Aero/Auto Aluminum Manufacturer Expands Heat Treatment

Taiwan Hodaka Technology, an aerospace and automotive manufacturer, extends its market reach by adding an aluminum aging furnace to its heat treatment capabilities. The furnace, which is designed for aging using T77 technology, will allow the company to meet the highest safety and strength standards.

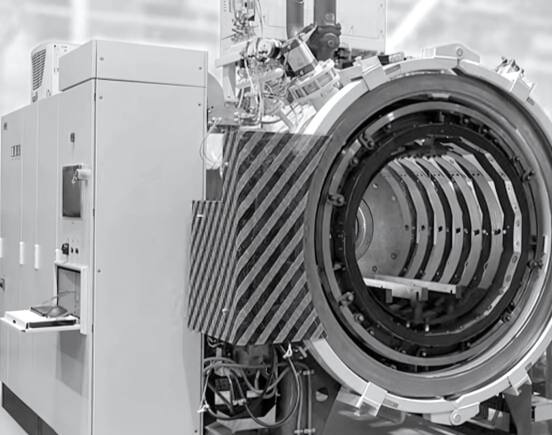

This is the first transaction between Taiwan Hodaka Technology, which is involved in the design and processing of parts made of aluminum alloys, and SECO/WARWICK. The furnace operates in the temperature range from 176° to 428°F (80° to 220°C) with a temperature uniformity in the last heating phase, of ±47.4°F (3°C) in accordance with the AMS 2750 standard.

“The solution supplied by SECO/WARWICK will allow us to enter a new market segment. We are a partner for many key players in the aviation industry. The T77 aluminum aging furnace will enable us to serve customer requirements even better. At the same time, the new technology will support our commitment to reducing our impact on the environment,” said Dr. Sam Chiang, vice president for R&D at Taiwan Hodaka Technology Co. Ltd.

For heat treated alloys (2xxx, 6xxx and 7xxx series), the letter T and one or more digits are used after the alloy series symbol. The first digit is the most important, as it indicates the type of heat treatment applied to the alloy, while the remaining digits (if provided) indicate heat treatment variants or their modifications. The 7000 series of aluminum alloys have the highest strength of all other aluminum alloy series and are commonly used in aviation since they are held to the highest safety and strength standards.

“T7 denotes the process of solution heat treatment and artificial aging to an overaged state to obtain specific properties, e.g. increased corrosion resistance,” said Tomasz Kaczmarczyk, sales manager of the Aluminum Process and CAB Furnaces Team at SECO/WARWICK. “Sometimes, in addition to the digit denoting the standard heat treatment, an additional digit is used to denote modifications to the given treatment or stress relief procedures. For example, for 7xxx alloys, the symbol T77 denotes retrogression and re-aging. The use of this process improves the alloy’s corrosion resistance, which is so crucial in the production of aircraft parts. The applied technology will allow Taiwan Hodaka Technology to produce high-quality profiles used in the aviation industry in accordance with the AMS standard.”

Vice President of Aluminum and CAB Products Segment

SECO/WARWICK

“The furnace on order equipped with electric heating will process 1500 kg of aluminum profiles with a maximum length of 5500 mm. This is a two-zone solution with a total heating power of 420 kW. The solution for aluminum aging, powered by electric heaters, eliminates the problem of CO2 emissions and is in line with the ecological trend increasingly common in heavy industry,” said Piotr Skarbiński, vice president of the CAB and aluminum products segment at SECO/WARWICK.

The furnace will be used at the company’s newly built plant in Taiwan.

The project partner was PEERENERGY, which offers thermal process consulting, project management, and equipment supply for the aerospace, military equipment, and semiconductor industries.

The press release is available in its original form here.

Find heat treating products and services when you search on Heat Treat Buyers Guide.Com

Aero/Auto Aluminum Manufacturer Expands Heat Treatment Read More »