Manufacturer Upgrades Hot Zone For Aerospace Industry

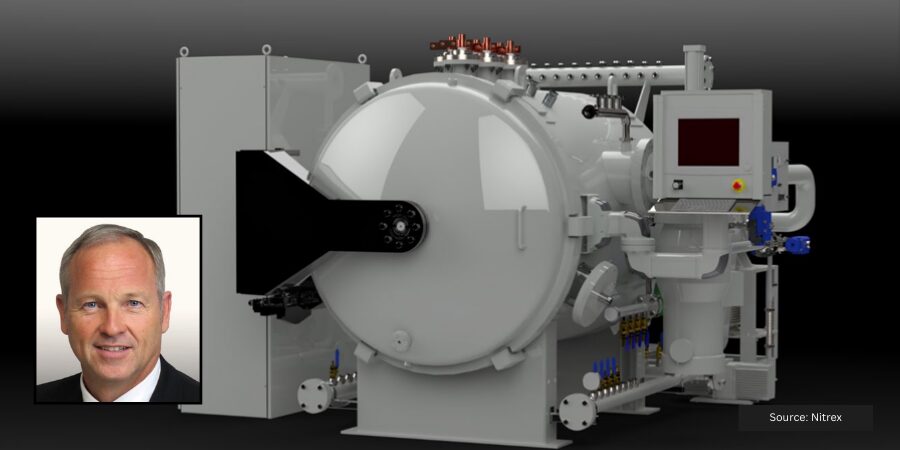

A prominent United States-based global aerospace company replaced a hot zone for their vacuum furnace. The company performs thermal processing on a variety of critical aerospace components used across multiple aircraft platforms.

Aftermarket Sales Manager

Solar Manufacturing

Source: Linkedin

Solar Manufacturing was contracted to replace an Ipsen VFC-924 hot zone.

John Hahn, aftermarket sales manager at Solar Manufacturing, noted: “They trusted our engineering and service teams to design and build a hot zone with key modifications that would enhance performance and longevity.”

The hot zone was implemented with improvements to boost hot zone efficiency, serviceability, and lifespan, such as graphite felt insulation for thermal efficiency, CFC 0.050” hot face for increased durability, and CFC edge trim throughout (door, bottom, and top bung) to extend hot zone life.

Press release is available in its original form here.

Find heat treating products and services when you search on Heat Treat Buyers Guide.Com

Manufacturer Upgrades Hot Zone For Aerospace Industry Read More »