Modern rotary-wing aircraft propulsion systems rely on different types of gears to transmit power from the turbine engines to the rotors. The basic requirements of these gears are that they are high strength, sustain long life, meet weight considerations, and have a high working temperature and low noise and cost, among others.

Most importantly, these gears require a hard, wear-resistant surface with a ductile core.

Gas carburizing is the current heat treat method used to produce these aircraft quality gears, but this method of heat treatment is costly due to the large number of process steps, huge footprints, energy consumption, and environmental issues. Moreover, the final grinding of gear teeth to correct distortion produced during quenching reduces effective surface compressive stresses.

An investigation into low-cost alternatives for surface hardening aerospace spur gears was conducted where specimens of the selected gears were induction hardened using a patented process. Dimensional and microstructural analyses were conducted, and residual stress studies were performed. This article is a summary of the steps and observations of the case study that resulted from this investigation, which can be summarized this way:

The proposed induction process is a low-cost alternative to conventional gas carburization. In some applications, a 25% savings is estimated.

The first step to gear manufacturing demands a total understanding of aerospace gear requirements. As the gear transmits torque, the teeth are subjected to a combination of cyclic bending, contact stresses, and different degrees of sliding or contact behavior. It is, therefore, critical for a gear to have the proper case and core structure to withstand these loading conditions.

With every revolution, a cyclic bending load is applied, resulting in tensile stress at the root region of the gear. The core of the gear has to be soft to absorb impact load and prevent brittle failure. Due to high-speed contact between adjacent gear teeth, peak shear stresses generated at the surface act in the normal direction to the surface. Pitting, spalling, or case crushing types of failures can occur due to low residual stress or inadequate case depth.

For aircraft quality gears, typical surface hardness is around 58Rc to 60Rc. The case depth is in reference to 50Rc and is controlled by diametral pitch.

Carburization

Carburization hardening is the most widely used technique for surface hardening of aerospace quality gears. A brief introduction to carburization is necessary to understand the potential benefits of this process and how other surface transformation can improve on some of the drawbacks of this commonly used process.

After raw material is received, it is forged to achieve proper grain structure and core hardness. The alloy most commonly used is ASM 6260 (AISI 9310). This low carbon alloy steel exhibits high core toughness and ductility.

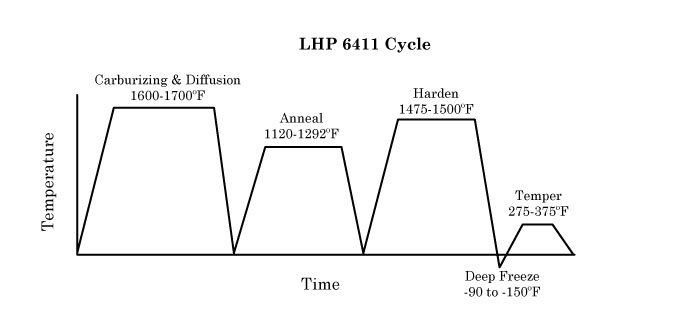

Parts are loaded in a furnace and heated to 1650ºF – 1750ºF in a carbon rich atmosphere, where approximately 1% carbon potential is maintained. The depth and level of carbon absorption depend on carbon potential, temperature, time inside the furnace, and the alloy content of the material. After the desired carbon gradient is achieved, the gears are cooled slowly. Then the parts are heated to austenitizing temperature and quenched.

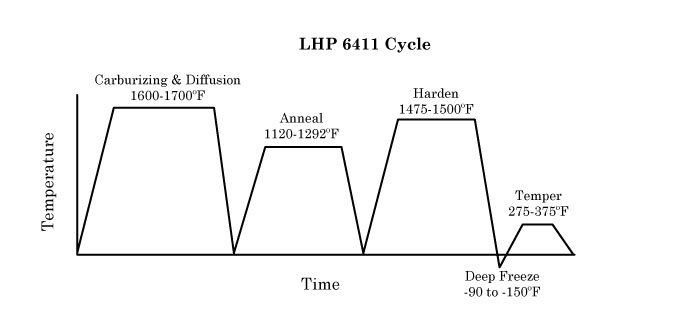

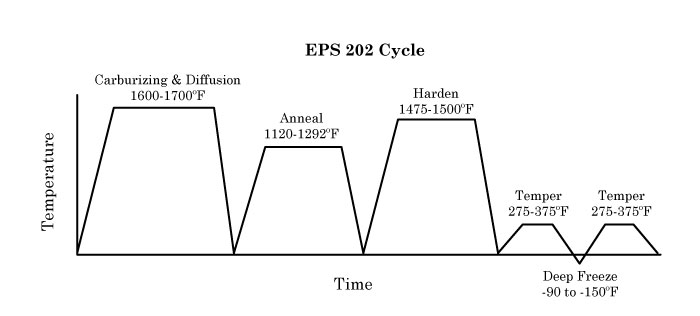

The process depends on the size, geometry, dimension tolerances, and other gear requirements.

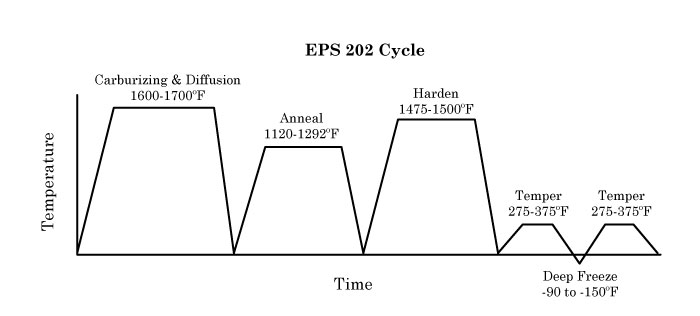

The heat treat cycles shown above are two commonly used carburization processes. The difference in post carburization steps depends on the alloy used and final product requirement.

The characteristic of carburization is the inherent distortion associated due to the difference in cooling rates between the thin web and thicker rim. Distortion can occur as a size growth, a change in involute profile, or the loss of crown in spur gears.

Case Hardening by Selective Heat Treatment

The number of process steps required to case carburize a gear can be significantly reduced only if the gear tooth surface areas are heat treated.

Processes for locally heating only the tooth surface include induction, flame, laser, and electron beam.

In order to use induction, steel with a minimum of 0.5% carbon must be used. Several different alloy steels were experimented with, such as AMS 6431, AlSl 6150, and AlSl 4350/4360/4370. These steels were selected due to their combination of toughness, temper resistance, hardenability, and strength. The hardened case is obtained by heating a specific volume of the tooth surface above the transformation temperature for that material. Rapid contour heating produced a case of martensitic structure around the profile-hardened area, resulting in high compressive residual stress at the surface at the root fillet. This compressive stress increases the tooth bending fatigue life, where tensile stress exists due to tooth bending.

Transformation hardening allows a significant reduction in process steps and associated fabrication costs, due to two different factors:

- Since sufficient carbon is already present in the base material, copper masking, plating, stripping and carburization steps are eliminated.

- In selective hardening, the area of the heated zone is limited to only the hardened sections, and distortion is minimal and predictable.

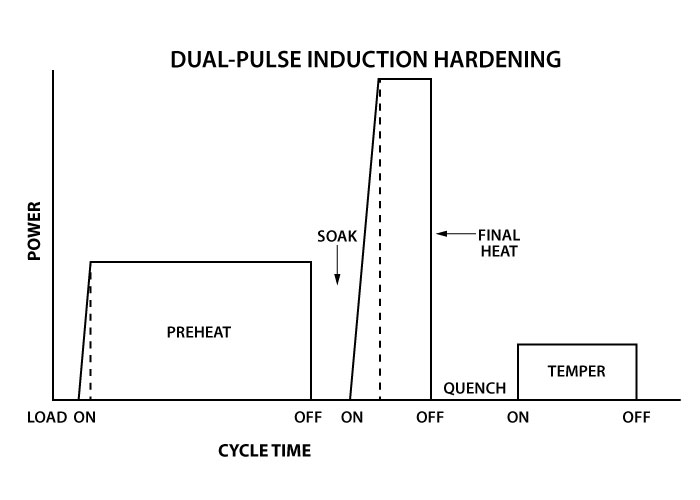

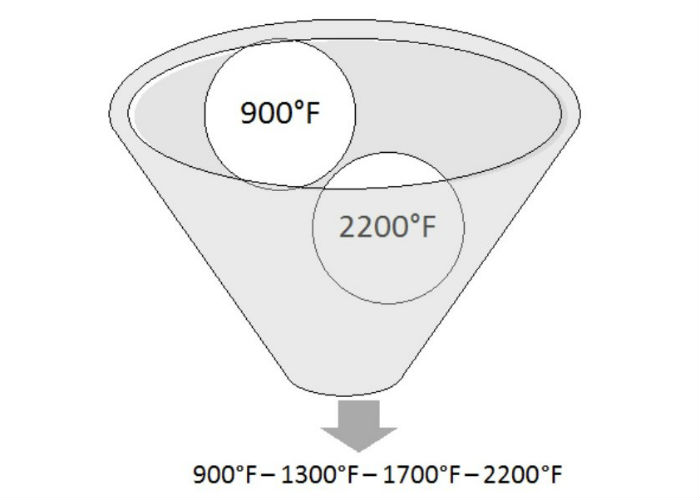

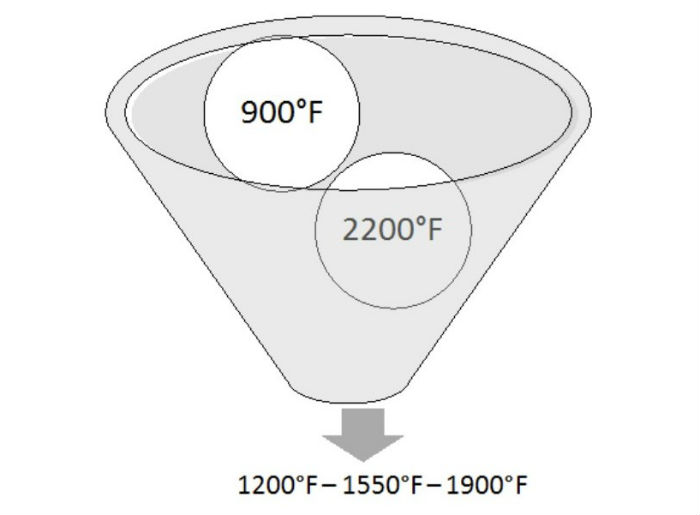

Surface hardening applications are generally controlled by three process parameters, namely frequency, power level, and time. In this respect, several different hardening processes have been used for gear hardening. The proposed method discussed in this presentation is known as Dual Pulse Induction Hardening (DPIH).

DPIH Process

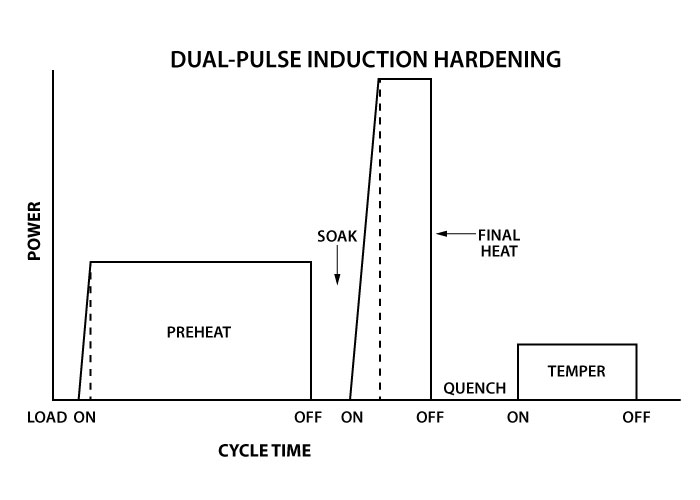

The DPIH is a patented process (U.S. patent #4,639,279). The process uses single frequency for both the preheat and final heat cycles. Two different power levels are used. This allows the entire process to be performed in one setup, using a single solid-state power supply.

The DPIH process consists of the steps described below:

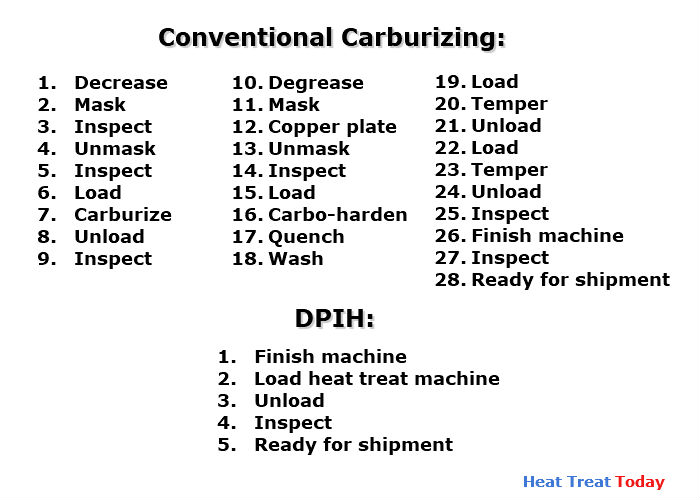

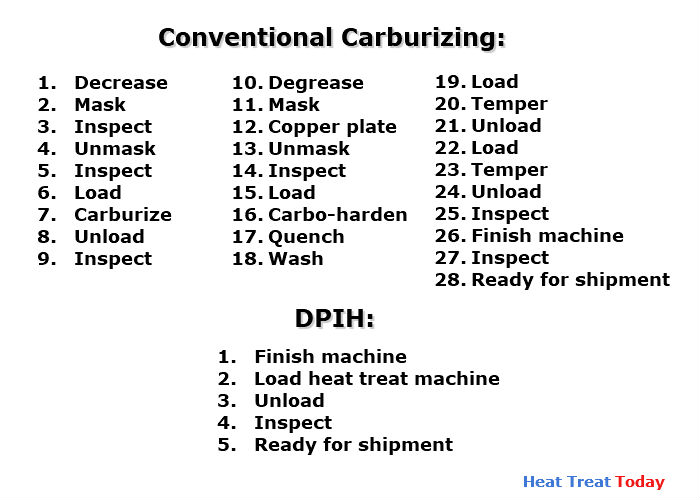

The heat treatment process steps for both the carburized and DPIH processes for the aircraft gear are compared below:

An 85% reduction in heat treat process steps occurs when the gear hardening method is changed from conventional gas carburization to DPIH.

Conclusion:

Comparison of the above data and the conventional carburization process to DPIH process.

Carburizing grade material has to be changed from low carbon to medium carbon steel for induction hardening. In both the processes, surface hardness achieved is comparable, but the characteristic of induction hardening is that the gear section maintains a constant hardness value from the surface up to the transition zone, where it rapidly drops to core hardness levels, unlike a more gradual decrease in hardness in case of carburized gears. Low distortion of induction hardening gear is also a major cost reducing factor.

Acknowledgment:

This work was performed at AGT, Division of General Motors.

Madhu Chatterjee is founder and president of AAT Metallurgical Services LLC in Michigan with extensive experience in advanced engineering, research and development, and process and product improvement. He is also one of the original dozen consultants that inaugurated Heat Treat Today’s Heat Treat Consultants resource page. You can learn  more about Madhu Chatterjee here.

more about Madhu Chatterjee here.

Look for more on aerospace heat treating in the upcoming special aerospace manufacturing edition of Heat Treat Today.