What if your furnace could run faster, cheaper, and cleaner — without major capital investment? Carl Nicolia, president at PSNERGY, LLC, discusses how using waste heat recovery and smart combustion monitoring can cut cycle times in half, reducing gas consumption, and eliminating zone temperature variations.

This informative piece was first released in Heat Treat Today’s October 2025 Ferrous & Nonferrous Heat Treatments/Mill Processing print edition.

Optimizing combustion and reclaiming waste heat can dramatically improve furnace performance. A real-world bar and coil annealing case study shows how simple retrofits reduced ramp cycle time, cut gas consumption, and eliminated zone temperature variation. The results demonstrate how heat treaters can boost throughput, lower costs, and improve quality without major capital investment.

The Challenge of Industrial Furnace Efficiency

Industrial furnaces are the backbone of metals processing, enabling heat treatment, annealing, forging, and countless other applications. Despite their importance, these furnaces are inherently inefficient. In most cases, less than half of the energy generated by burning natural gas actually reaches the load. Energy is continuously lost through exhaust gases, radiant losses, opening losses, and the heating of fixtures and refractory walls.

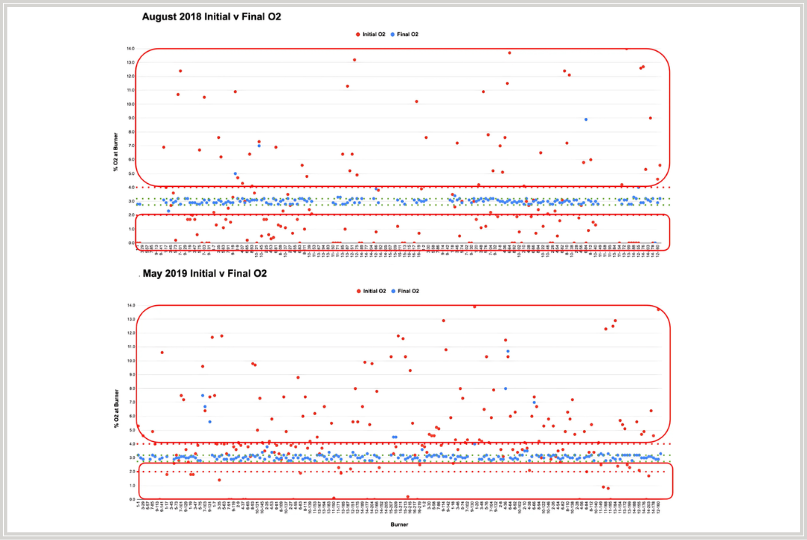

On top of this inefficiency, combustion ratios drift over time. Burners fall out of tune, air-to-fuel ratios shift, and temperature distributions across zones become imbalanced. Even with regular maintenance, most furnaces run well below their optimal performance for a significant portion of their operating lives. See figures 1a and 1b, which illustrate how quickly furnaces drift out of tune. Therefore, regular monitoring and adjustment are essential to avoid energy losses and reoccurring performance issues.

This raises a critical question for heat treaters and metal processors: how much efficiency is being left on the table? And more importantly, what would it mean for throughput, energy costs, and product quality if some of that efficiency could be reclaimed?

The following case study of a bar and coil annealing furnace provides a compelling answer.

The Application

The facility in this example operates a batch furnace dedicated to bar and coil annealing. The furnace is equipped with 14 non-recuperated U-tube burners across two heating zones.

While reliable, the furnace faced two persistent challenges: long cycle times and inconsistent temperature uniformity across the two zones. Both issues reduced throughput and posed risks to product quality and delivery while also driving up energy costs.

The Problem

The problems facing this manufacturer were not unusual. Long cycle times limited furnace productivity, creating bottlenecks in meeting customer demand. At the same time, uneven zone temperatures made it difficult to maintain uniform metallurgical properties in the product.

With natural gas prices trending upward, energy costs compounded the problem. Every additional hour in the cycle not only resulted in lost throughput, but also higher gas consumption.

The Objective

The project set out with three clear objectives:

- Reduce total cycle time: By shortening ramp-up time, the furnace could complete more loads per month, increasing throughput.

- Improve zone uniformity: Temperature variation between zones not only affected quality but also required longer soak times to ensure the coldest parts of the load met specifications. Eliminating this variation would allow for both higher quality and shorter cycles.

- Lower gas consumption: With energy representing a major portion of operating costs, reducing fuel usage was essential to improving competitiveness and profitability.

The Solution

This improvement method went beyond the traditional practice of tuning a furnace every six to twelve months. Instead, it involved a broader approach utilizing waste heat recovery and digital monitoring tools to achieve optimal combustion at every burner.

The process involved:

- Installing ceramic radiant tube insert assemblies into the U-tubes

- Utilizing a combustion monitoring and alerting system to measure air-to-fuel ratio at all burners on the furnace

- Adjusting all burners to operate within an optimal excess oxygen window (typically between 2.8% and 3.2%) and maintaining those settings over time

- Ensuring balance between zones allowing the furnace to deliver uniform heating to the load

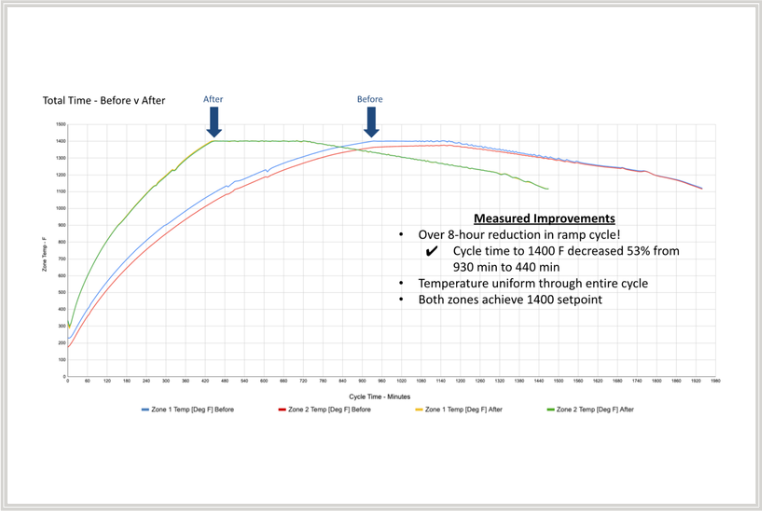

The project began with installing waste heat recovery on all 14 of the non-recuperated U-tubes. In this case, ceramic radiant tube inserts (RTIs) were used because they are quickly and easily installed and capture waste heat normally lost out the exhaust, keeping the energy inside the furnace. Additionally, the RTIs improve temperature uniformity, and reduce gas consumption (see Figure 2).

Installing combustion monitoring at each burner is key to keeping the improvements in place. Instead of waiting for issues to show up in product quality, operators can see what is happening at the burners in real time. When a burner starts drifting out of balance or tune, they have the data to correct it immediately. Constant visibility helps the furnace stay efficient and consistent.

Precision is important when considering the physics of combustion. Measuring excess oxygen at less than 1% (running rich) indicates incomplete combustion is occurring, leading to carbon monoxide and soot formation. At the other extreme, running with too much excess air (running lean) wastes energy. Even 5% excess oxygen results in roughly 13% less energy to the load, while 7% excess oxygen increases those losses to 21%, all while burning the same amount of natural gas.

The Results

The outcomes of this project were dramatic.

- Ramp cycle reduced by 53%. Prior to any improvements, the furnace cycle time was 30 hours, with ramp-up time accounting for a major portion of the overall cycle. After optimization, ramp-up time was reduced by 8 hours, enabling faster turnaround and greater throughput.

- Gas consumption reduced by 59% per load. Improved combustion efficiency means that less fuel is required to reach the same metallurgical results. This reduction directly lowers operating costs and CO2 emissions per ton.

- Zone temperature variation eliminated. By balancing combustion across zones, the furnace achieves uniform heating, reducing the risk of quality issues and minimizing the need for extended soak times.

For the manufacturer, these results translated into both immediate savings and long-term operational advantages. Throughput increased while emissions and quality risks were reduced (see Figure 3).

Broader Implications for Industry

While this case study focuses on a single bar and coil annealing furnace, its implications extend across the heat treat and metals industries.

Most industrial furnaces, regardless of size or application, experience similar inefficiencies. Over time, combustion drifts away from optimal conditions, often unnoticed until performance or quality issues arise. Standard practice, tuning once or twice a year, is rarely enough to maintain proper function.

Capturing waste heat and utilizing technology to monitor and maintain combustion represent major opportunities for manufacturers. By reclaiming even a portion of the 10–30% efficiency losses that occur between tunings, facilities can realize double-digit improvements in throughput and energy consumption.

The return on investment can be substantial. In most cases for these improvements, it’s months. Additional throughput alone will often justify the investment. In many locations, natural gas providers have incentives in place for these projects as they are proven to make substantial reductions in energy use. Just as important, optimizing combustion extends the life of burners and tubes, reduces maintenance emergencies, and stabilizes furnace operation; again, reducing cost and improving efficiency.

Conclusion

Industrial furnaces are indispensable, but they do not have to be inefficient. This bar and coil annealing case study demonstrates that even established furnace systems can achieve impactful performance gains through retrofit combustion optimization.

By focusing on cycle time, energy use, and zone uniformity, manufacturers can unlock faster throughput, lower costs, and higher product quality, while also reducing emissions and operating stress.

The lesson for heat treaters is clear: combustion is not just a background process, it is the heartbeat of the operation. Maintaining combustion properly through the use of easily implemented technology can turn a productivity drain into a competitive advantage.

About The Author:

President

PSNERGY, LLC

Carl Nicolia is president of PSNERGY, LLC, which provides modern solutions to combustion problems, improving equipment life, enhancing productivity, and reducing emissions through smart application of proprietary products, services, and technology.

For more information: Contact Carl Nicolia at cnicolia@psnergy.com.