A leading aviation technology company will receive two new furnaces from a manufacturer of metal heat treatment solutions with North American locations. The furnaces will be used in the production of engine components, particularly directionally solidified and single crystal castings.

CEO

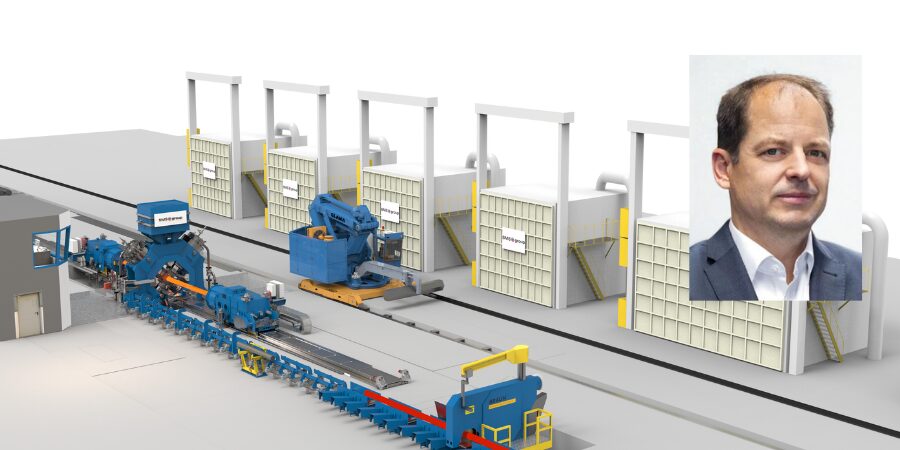

SECO/WARWICK Group

SECO/WARWICK will provide a Vector vacuum furnace and a VIM JetCaster furnace with a capacity of 25 kg, enabling the melting of nickel and cobalt alloys at temperatures up to 1700℃ (3092°F) to the Chinese aviation manufacturer.

“The device ensures a low percentage of casting defects, both macro and microstructural, as well as a significant reduction of the directional solidification casting process compared to the classical process due to increased mold withdrawal speeds,” said Sławomir Woźniak, CEO of SECO/WARWICK Group.

The latest jet engines use advanced blades cast produced by single crystal technology. The control system meets the needs of precise processes: casting, temperature control, as well as comprehensive data collection.

The Vector vacuum furnace is designed for aging and solution heat treatment processes. It achieves a maximum temperature of 1400℃ (2552°F) with a uniformity of ±5℃ (9°F) and can handle components with a total mass of up to 800 kg. Due to a high level of vacuum (up to 10⁻³ Pa), processes take place without intergranular oxidation, resulting in a quality surface for the components.

Press release is available in its original form here.