A tinplate company will receive a new order for a tinplate coating line (TCL) and tinplate double reduction mill (TDRM) from a company with North American locations specialized in sustainable thermal processing solutions for the metals and mining industries.

Chief Representative Officer of South East Asia and Oceania

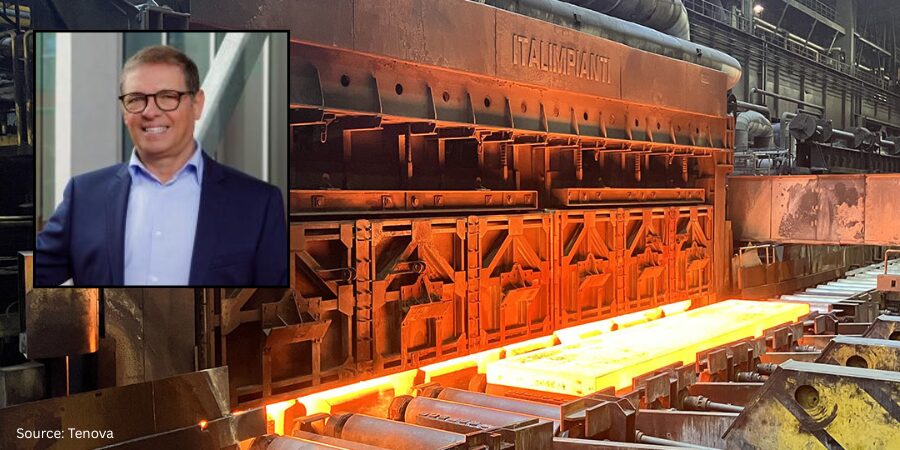

Tenova

Source: Tenova

These orders from Tenova are for the Tinplate Company of India Ltd., a subsidiary of Tata Steel, for its new Tinplate Complex at the Jamshedpur plant in Jharkhand, India.

The TCL includes an independent pre-tinning section with sulfuric acid for iron control in the electrolyte solution and an advance tinplate coating control close loop to achieve the best strip coating quality and stability. The IGBT AFE rectifier technology allows for efficiency in tinplate coating which moreover allows for low electrical consumption.

The TDRM plays a key role in obtaining a combination of ultra-light strip gauge and required hardness. This mill is equipped with automatic gauge control (AGC) cylinders, an automatic flatness control (AFC) system, a roughness control system, and a dedicated reduction control for double reduced (DR) tin plate.

Giuseppe Zanzi, chief representative officer of South East Asia and Oceania at Tenova, commented, “We are very proud to have been selected as the main technological partner for Tata Group tinplate expansion. Thanks to our solutions, Tata will be able to achieve a sustainable production based on low electrical consumption and very large production capacity.”