A Cincinnati-based heat treat technology solutions provider recently completed a controls and software upgrade for the bearings brand of an engineering and manufacturing group at the latter’s facility in Dahlonega, Georgia, including instrumentation and software for hardening furnaces, quench, washer/rinse, and temper equipment.

Super Systems Inc. and JTEKT Corporation’s Koyo Bearings  brand announced that the scope of the upgrade includes all engineering, installation, controls, and software for Koyo’s gas-fired hardening furnace line. The new automation included a turnkey retrofit of new control cabinets as well as software necessary for furnace control and historical process data review. The controls and software provide JTEKT with the confidence to heat treat parts to meet the highest standards with complete traceability for its Koyo brand bearings.

brand announced that the scope of the upgrade includes all engineering, installation, controls, and software for Koyo’s gas-fired hardening furnace line. The new automation included a turnkey retrofit of new control cabinets as well as software necessary for furnace control and historical process data review. The controls and software provide JTEKT with the confidence to heat treat parts to meet the highest standards with complete traceability for its Koyo brand bearings.

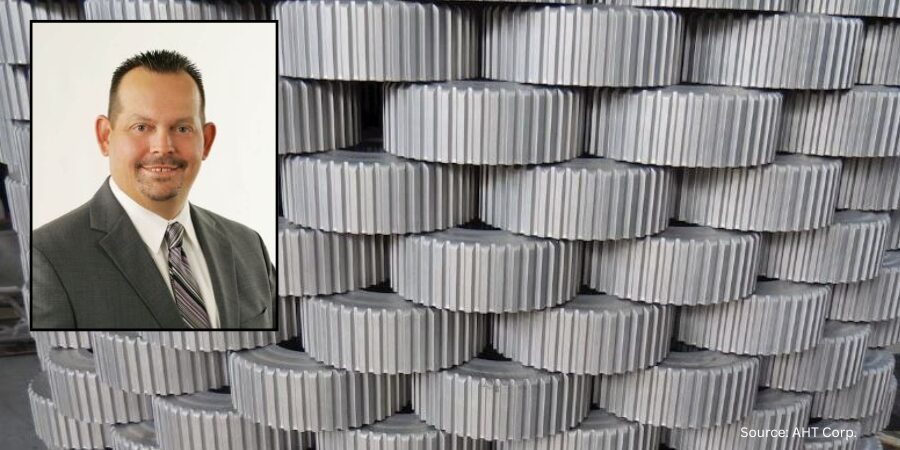

“We have been fortunate to work with JTEKT on a number of automation projects over the years and we are looking forward to participating in more innovative heat treating opportunities in the Dahlonega facility,” says Bob Fincken, Super Systems National Sales Manager.

“SSi’s ability to understand our needs and provide customized solutions has been a tremendous benefit to us,” says Michael Rebula, Heat Treat Supervisor at JTEKT.