From the wheels of the Mars Curiosity robot to aircraft wings that can fold to different angles while in the air, NASA's Glenn Research Center in Cleveland is expanding the applications for a newly developed alloy that can "remember" and return to its original shape.

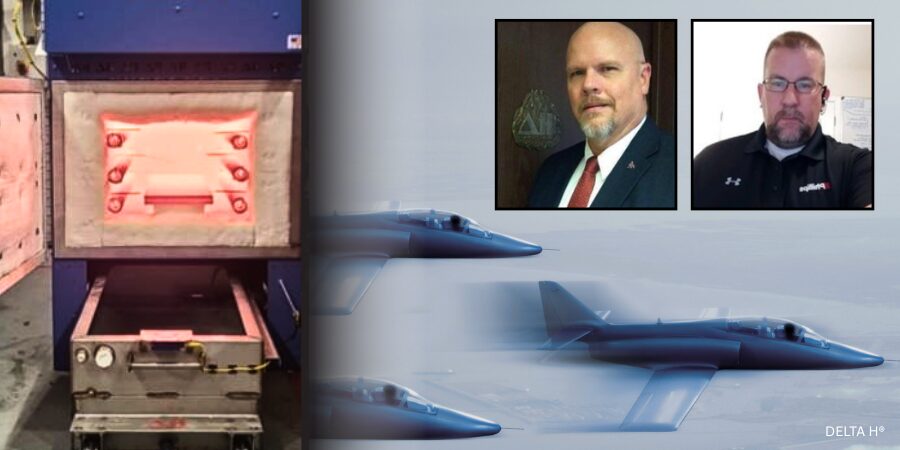

In December, Heat Treat Today reported on tires made from heat-treated, shape-memory alloy that results in a woven-mesh metal to provide NASA’s Curiosity robot an easier ride across the rough terrain of Mars. Earlier in January, NASA announced the recent flight series of Ptera, an aircraft with specially made wings meant to improve aerodynamics. The test maneuvers, which took place at NASA’s Armstrong Flight Research Center in California, were part of the Spanwise Adaptive Wing project, or SAW, which aims to validate the use of a cutting-edge, lightweight material to be able to fold the outer portions of aircraft wings and their control surfaces to optimal angles in flight, resulting in multiple in-flight benefits to to aircraft in the future, both subsonic and supersonic -- flying faster than the speed of sound.

SAW, which is a joint effort between Armstrong, NASA’s Glenn Research Center in Cleveland, or GRC, Langley Research Center in Virginia, Boeing Research & Technology in St. Louis and Seattle, and Area-I Inc. in Kennesaw, Georgia, intends to obtain a wide spectrum of aerodynamic benefits in flight by folding wings through the use of an innovative, lightweight material called shape memory alloy. This material is built into an actuator on the aircraft, where it has the ability to fold the outer portion of an aircraft’s wings in flight without the strain of a heavy hydraulic system. Systems with this new technology may weigh up to 80 percent less than traditional systems.

The recent series of flight tests at Armstrong successfully demonstrated the material’s application and use by folding the wings between zero and 70 degrees up and down in flight. The shape memory alloy is triggered by temperature and works by using thermal memory in a tube to move and function as an actuator. Upon being heated, the alloy would activate a twisting motion in the tubes, which ultimately moves the wing’s outer portion up or down.

During the SAW test flights, which included long legs of flight in which the necessary maneuvers for the research could be done, onboard controllers heated and cooled the SAW actuators, folding the wing panels to different angles between zero and 70 degrees.

"We put the SAW technology through a real flight environment, and these flights not only proved that we can fly with this technology, but they validated how we went about integrating it," said SAW Principal Investigator Matt Moholt. "We will use the data from these flights to continue to improve upon the actuation system, including speed and smoothness of actually folding the wings, and we’ll apply them as we get ready to fly again in 2018."

Does anyone know the alloy being used in this application? If so, please email editor@HeatTreatToday.com, and we’ll repeat your answer to our entire audience once we receive it.

Heat Treat Today's report on memory shape tires: "NASA Reinvents Wheel: Heat Treated, Shape-Memory Tires"

NASA’s news release and related videos: "NASA Tests New Alloy to Fold Wings in Flight"

The NASA flight test, posted at NASA Armstrong Flight Research YouTube channel: