A company in advanced metal casting technologies has shipped its first commercial additive manufacturing evaporative casting (AMEC) machine to the University of Tennessee, Knoxville (UTK). The system will be installed at UTK’s manufacturing research facility, where it will support continuing education, casting research, and workforce development in next-generation manufacturing.

Lightning Metal LM-16 is Skuld LLC‘s flagship machine for additive manufacturing evaporative casting (AMEC). The machine is a tool-less, net-shape casting process capable of producing aerospace grade aluminum and other high-performance alloys with minimal post-processing. The system enables rapid prototyping, reduced lead times, and flexible alloy compatibility, making it ideal for both industrial and academic environments.

Source: Skuld LLC

Founder & CEO

Skuld, LLC

Source: Author

“This milestone represents…a signal that advanced casting is entering a new era,” said Sarah Jordan, co-founder and chief executive officer at Skuld. “The University of Tennessee is a national leader in manufacturing innovation, and we’re proud to support their mission with a system that bridges research and real-world application.”

Director, Sales and Marketing

Skuld

Source: Linkedin

UTK will use Lightning Metal LM-16 platform to expand its materials science curriculum, conduct applied research in casting and alloy development, and provide hands-on training for students and professionals entering the manufacturing workforce.

“This is exactly the kind of partnership we envisioned when we launched the Lightning Metal platform,” said Adam J. Penna, director of sales and marketing at Skuld. “It’s a platform that empowers innovation in evaporative casting utilizing 3D printing for improved features like edges and surfaces while also reducing the need for tooling cost…whether you’re solving supply chain challenges or training the next generation of engineers.”

The Technology

Skuld’s AMEC technology merges lost foam with polymer 3D-printing. Heating up to around 2000°F, the machine operates as an automated micro-foundry. The Lightning Metal LM-16 removes the safety issues of handling molten metal and is perfect for small, custom, one-off aluminum parts fasteners. It makes products in a 7″ cube, melting approximately 16lbs of aluminum, and can also process brass or bronze.

The machine is sized to be able to move through standard doorways and utilizes single-phase power, like a dryer plug.

The casting works by utilizing a hollow polymer shape in place of lost foam, where the molten metal vaporizes the polymer. This is a subset of the casting field called lost foam, which is a variation on lost wax investment casting, and eliminates around 90% of process steps, making for fewer costs and a faster process. The mold is insulated with a thin ceramic shell, ceramic beads, a metal container called a flask, and unbonded beads.

Source: Skuld LLC

Source: Skuld LLC

Source: Skuld LLC

Source: Skuld LLC

Heat Treat Today asked what difficulties Skuld faced in developing this technology. The development process faced several unique hurdles, such as heat retention due its small size (compared with a large furnace), as well as crafting the machine’s automation while not allowing it to be hackable.

Applications

Source: Skuld LLC

The Lightning Metal LM-16 is for those without an in-house foundry. It works well for replacement parts for in-house heat treatment, for example: hooks, baskets, or rollers. The machine can also produce spare parts or be utilized for prototyping pieces that can be used by higher volume machines. The Lightning Metal LM-16 operates well at around one hundred pieces per year.

The AMEC technology eliminates machining (which reducing costs for clean machining), and drives down the cost substantially associated with cooling for lost foam. The process also avoids HIPing, reducing the need for powder bed fusion parts.

The system enables reverse-engineering for discontinued items, and could be particularly applicable for heavy equipment, agriculture, compressors, and railroads.

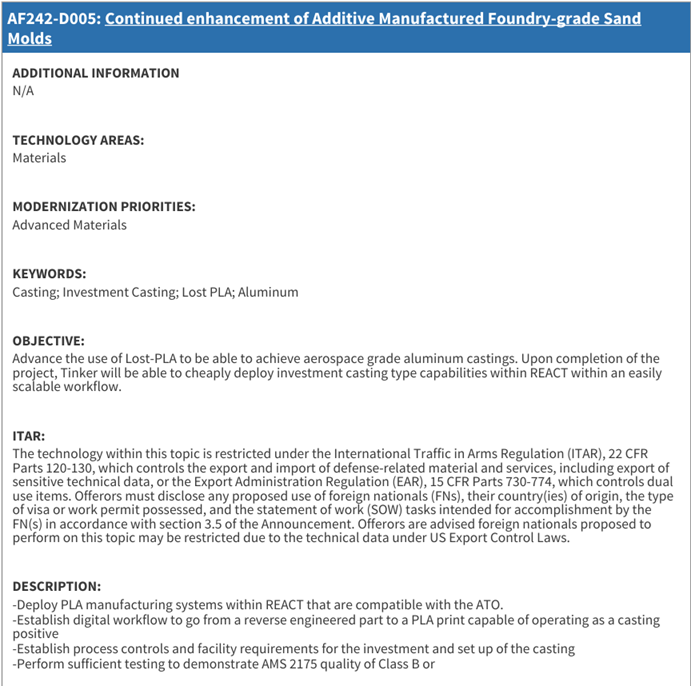

The Lightning Metal LM-16 deployment marks a major step in Skuld’s commercialization strategy, following over $9 million in Department of Defense contracts and successful pilot programs with the U.S. Air Force and Defense Logistics Agency. The company was recently awarded an SBIR for additive manufacturing.

For more information on this technological innovation, please contact Adam Penna at apenna@skuldllc.com.