Heat Treat Today’s Technical Tuesday feature means that on just about any given Tuesday, there will be an article that aims to educate our heat treating readers — be it in a process, equipment, metals, analysis, critical parts, or more. Enjoy this sampling of Technical Tuesday articles from the past several months.

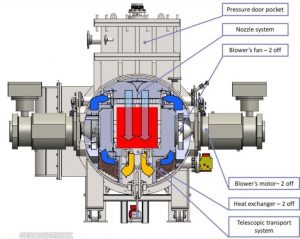

Case Study: Heat Treat Equipment Meets the Future Industry Today

Source: SECO/WARWICK

How has one heat treat furnace supplier contended with modern challenges of manufacturing? In this case study about a shift away from traditional forms of heat treat, explore how vacuum furnace technology has more technological horizons to bound.

Several key features discussed will be the various challenges that characterize modern industry; the differences between historical heat treat furnaces and vacuum furnaces; furnace features that can meet these obstacles; and a close look at what one equipment option from SECO/WARWICK helps. Additionally, explore the case study of a process that resulted in the following assessment: "all technological requirements have been met, obtaining the following indicators of efficiency and consumption of energy factors calculated for the entire load and per unit net weight of the load (700 kg)."

Read the entire article here.

How Things Work: Thermocouples

Source: Heat Treat Today

How do thermocouples work? How would you tell if you had a bad one? Those ever present temperature monitors are fairly straightforward to use, but when it comes to how it works — and why — things get complicated.

This transcript Q&A article was published in the print edition last year (2022), but there was too much information to fill the pages. Online, read the full-length interview, including the final conversation about how dissimilar metals create EMF. Included in the discussion is proper care of the T/C and knowledge of when it’s time to replace.

Read the entire article here.

6 Heat Treat Tech Trends Fulfilled in 2022

Source: Unsplash.com/getty images

What’s “hot” for heat treaters in recent months? The trends are pointing towards streamlining upgrading information systems, more efforts to reduce carbon footprint, and ensuring processes in salt quenching and electricity use are as efficient as they can be.

Each of the 6 trends included in the article demonstrates that heat treaters are making thoughtful and responsible decisions and purchases. Considerations include care for the environment and methods to help employees share and receive information needed for each job.

Read more about each of the trends to see what’s happening with equipment purchases and technology decisions and how companies are pushing to make that carbon footprint smaller.

Read the entire article here.

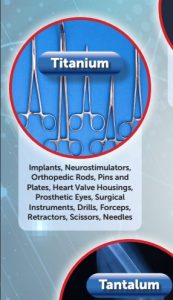

A Quick Guide to Alloys and Their Medical Applications

Source: Heat Treat Today

If you're pining for a medical heat treat quick resource in our "off-season," we have a resource for you. Whether you are a seasoned heat treater of medical application parts or not, you know that the alloy composition of a part will greatly determine the type of heat treat application that is suitable. Before you expand your heat treat capabilities of medical devices, check out this graphic to quickly pin-point what alloys are in high-demand within the medical industry and what end-product they relate to.

The alloys addressed in this graphic are: titanium, cobalt chromium, niobium, nitinol, copper, and tantalum.

Read the entire article here.

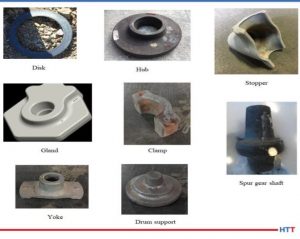

Resource -- Forging, Quenching, and Integrated Heat Treat: DFIQ Final Report

Source: Joe Powell

How much time and energy does it take to bring parts through forging and heat treatment? Have you ever tried to integrating these heat intensive processes? If part design, forging method, and heat treat quenching solutions are considered together, some amazing results can occur. Check out the report findings when the Direct from Forge Intensive Quenching (DFIQTM) was studied.

Forgings were tested, in three different locations, to see if immediate quenching after forging made a difference in a variety of steel samples. The report shares, “The following material mechanical properties were evaluated: tensile strength, yield strength, elongation, reduction in area and impact strength. Data obtained on the mechanical properties of DFIQ forgings were compared to that of forgings after applying a conventional post-forging heat-treating process.”

Read the entire article here.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com