A Canadian leader in the coating industry will expand their heat treat capabilities with a floor-standing box furnace used for ceramic coating applications for parts in the aerospace industry.

A Canadian leader in the coating industry will expand their heat treat capabilities with a floor-standing box furnace used for ceramic coating applications for parts in the aerospace industry.

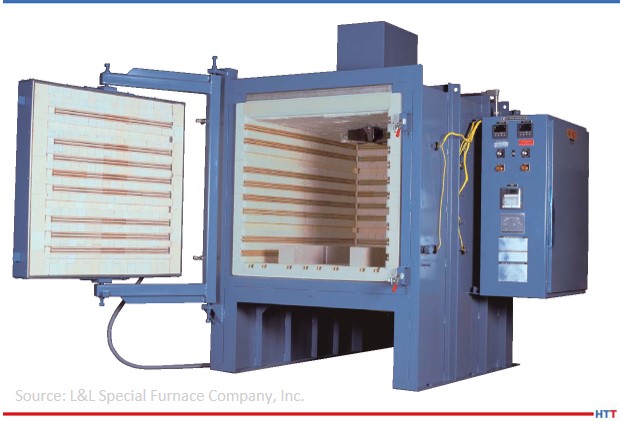

The L&L Special Furnace Company Inc. model XLE214 is used for curing and bonding ceramic coatings to various steel bodies. This process provides extra strength to aerospace parts that are subject to various heats and stresses under normal operating conditions.

The furnace has an effective work zone of 22" wide by 16" high by 20" deep. A horizontal door with ceramic hearth and support bricks is included to incorporate the customer’s loading system. Nickle chrome elements are used in the furnace that are resistant to any potential contamination the process may cause. Heat shields provide a safe-to-touch case temperature under operating conditions.

The model XLE214 is controlled by a Eurotherm program control with overtemperature protection, chart recorder with jack panel, solid-state relays, and zone controls for balance of temperature gradients. Thermocouples, fusing and electrical interconnections are included. The furnace control circuit is completely tested to ensure proper operation prior to shipping.

The furnace case is sealed for use with inert atmosphere to help reduce oxygen impregnation with the parts. The furnace has a manual inert flow panel to control the inert gas flow into the oven.

The model XLE214 also includes a high-convection fan for uniformity of ±10°F/5.5°C above 500°F/260°C to 1,875°F/1,023°C. There is a 4" diameter venturi with a variable frequency drive to evacuate outgassing that occurs during the curing of the ceramics to the steel part. The system is completely automated through the program control logic.