Solar Atmospheres, Inc. has announced that it has become the first company to receive MedAccred critical process reaccreditation. Furthermore, Solar Atmospheres, Inc. successfully expanded its scope of accreditation to include Hardness Testing and Metallography & Microindentation Hardness. MedAccred is an industry-managed critical process supply chain oversight program which was developed by leading medical device companies to improve device quality and most importantly enhance patient safety.

The effort to establish MedAccred began in 2010 when the Performance Review Institute (PRI) was asked to consider the development of a Nadcap-style special process supplier accreditation program for the medical device industry. An industry roundtable was organized and convened in 2012 among interested medical device companies and PRI. Following this roundtable meeting, briefings were held with the FDA Center for Devices and Radiological Health’s (CDRH) Office of Compliance and the FDA’s Office of Global Operations within the Office of the Commissioner. The program purpose and scope was discussed, along with the results of proof of concept audits which were conducted to demonstrate the program’s viability. The FDA provided positive feedback and strong encouragement to pursue the development of the program.

By 2014, several critical process Task Groups were operating on a formal basis, program documents were drafted, circulated and approved by the executives of the participating companies and audit criteria had been published in several critical process areas. Solar Atmospheres, Inc. committed to hosting the first MedAccred audit.

In early 2015 the first MedAccred critical process accreditation was issued to Solar Atmospheres Inc. for Heat Treating.

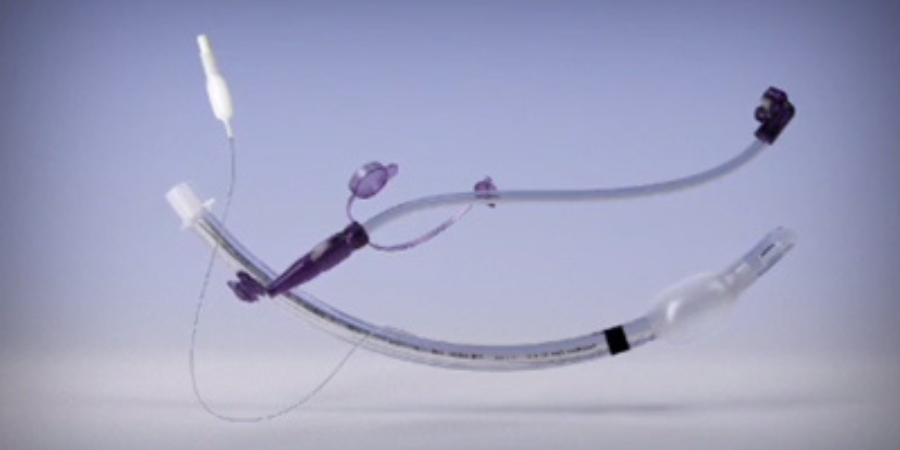

Today’s functioning critical process Task Groups include Cable & Wire Harnesses, Heat Treating, Plastics Injection Molding, Printed Circuit Board Assemblies, Sterilization and Welding. The industry managed task groups develop audit criteria, conduct audits, and award MedAccred Critical Process Accreditations to leading suppliers at all tiers in the Medical Device Supply Chain. Many companies are seeking MedAccred Accreditation to demonstrate their commitment to quality and patient safety. Future MedAccred Task Groups under consideration for development include Material Testing Laboratories, Assemblies, PCBs, Batteries, Chemical Processing, NDT, Cleaning, Coating, Optics, Packaging, etc. Active OEM and Contract Manufacturer participants include: Johnson & Johnson, Philips, Stryker, GE Healthcare, Medtronic, NYPRO Jabil, Steris, etc. The list of participating suppliers is growing steadily.

Joe Pinto, Executive Vice President and Chief Operating Officer of PRI explained the significance of Solar Atmospheres’ accomplishment: “Gaining a critical process accreditation from MedAccred is recognition of a company’s commitment to quality and the high standards of critical process manufacturing which they maintain. The successful completion of a reaccreditation audit is a clear indication that a company is able to consistently uphold those extremely high standards over an extended period of time. I would like to congratulate the whole team at Solar Atmospheres on this important achievement.”

![]() Source: Today’s Medical Developments

Source: Today’s Medical Developments