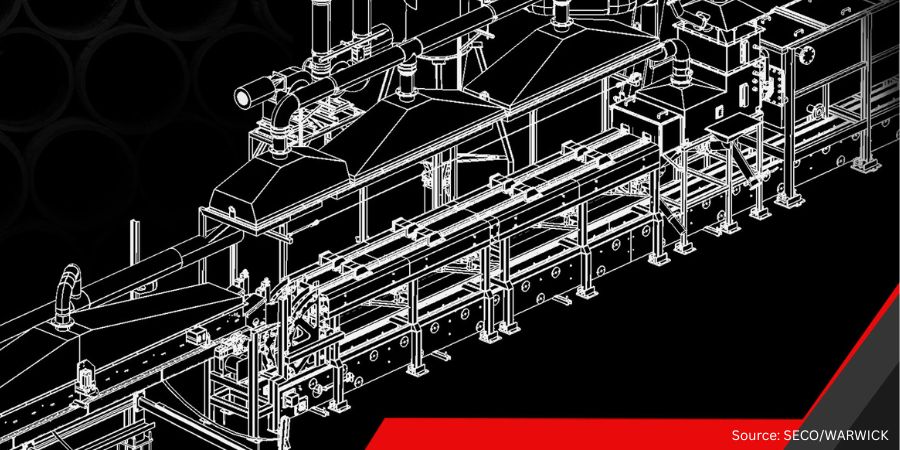

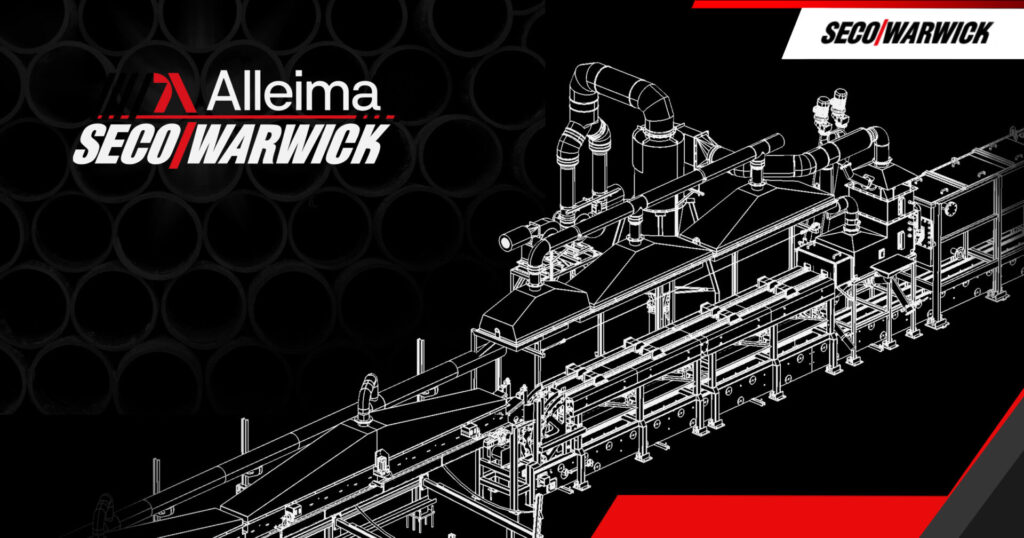

Tube Annealing Furnace for Stainless Steel and Special Alloys Manufacturer

Alleima, a manufacturer of steel components and special alloys, will receive a new tube annealing furnace. The electric atmospheric furnace line is intended for bright annealing of high-alloy tubes and will be used in the production of nuclear applications components.

SECO/WARWICK is providing the furnace as their 5,000th device.

Source: SECO/WARWICK

Vice President of Aluminum and CAB Products Segment

SECO/WARWICK

Production Unit Manager

Alleima

Source: LinkedIn

“Our partnership with SECO/WARWICK has lasted for many years. We are delighted that we could celebrate it in a special way, as our impressively large tube annealing line (over 140 meters long – 460 ft) happens to be the 5,000th SECO/WARWICK device. We feel that together we are creating not only a remarkable history, but also the future as this solution will help us spread our wings,” said Magnus Mellberg, production unit manager at Alleima.

“The furnace was created specifically for this partner’s needs. It will allow them to increase production capacity…This is important as the demand for high-alloy components in this market has increased. It is an unusual construction, verified through analysis and simulations, and implemented in reality. It offers very good technological results after the annealing process,” explained Piotr Skarbiński, vice president of the Aluminum and CAB Business Segments at the SECO/WARWICK Group.

Press release is available in its original form here.

Tube Annealing Furnace for Stainless Steel and Special Alloys Manufacturer Read More »