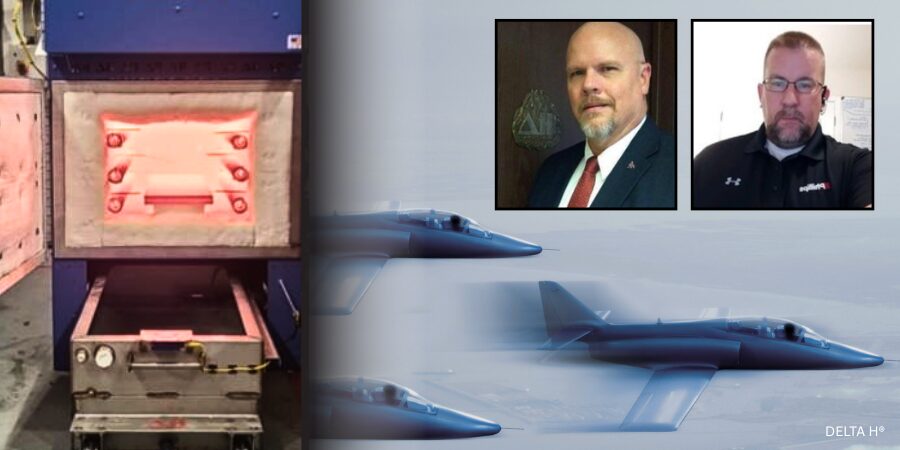

A Defender Series furnace has been provided for Al Udeid Air Base, providing the U.S. Air Force with mission-critical capability to heat treat all aviation-grade metals used in aircraft maintenance.

Source: DELTA H®

DELTA H® and Phillips Federal commissioned the dual-chamber system which features a radiant heat lower chamber (1,000°F–2,000°F, 12”W x 12”H x 48”D TUS volume) with inert atmosphere. A convection heat upper chamber (200°F–1,200°F, 18”W x 12”H x 48”D) is capable of rapid cooling from 1,000°F to below 200°F in under 30 minutes, allowing solution heat treating and aging (T6) in the same chamber before part freezing is required.

Source: DELTA H®

Source: DELTA H®

Commissioning included hands-on training and qualification of USAF Metals Tech personnel in system operation, AMS2750 compliance, TUS/SAT execution (via SuperSystems SDS 8120), pyrometry recordkeeping management, and heat treating fundamentals for aviation grade metals.

Director and CTO of DELTA H, Richard Conway, shares: “Mary and I were honored to work directly with the outstanding Airmen at Al Udeid — true professionals whose determination to master heat treating reflected their deep commitment to the mission. It was humbling to see our furnace system play a small part in supporting their readiness. In a time of growing uncertainty, DELTA H is proud to stand with our Warfighters on the front lines, providing the tools they need to defend freedom.”

Product Manager

Phillips Federal

Source: Linkedin

Product manager at Phillips Federal, USAF Retired, SMSgt, John (JD) Murray shares: “As a Retired USAF Aircraft Metals Technician with multiple deployments to my credit, I am overjoyed to see the deployed location receive the best equipment possible. DELTA H furnaces are essential to keep our aircraft flying, fighting, and winning.”

The furnace is equipped with a dual-bath quench tank supporting both water and oil quenching, and final testing confirmed AMS2750 compliance with the convection chamber achieving Class 1 (±5°F) and the radiant chamber Class 3 (±15°F) uniformity. PMEL completed all calibrations, certifying the system for immediate aircraft parts processing.

Press release is available in its original form here.