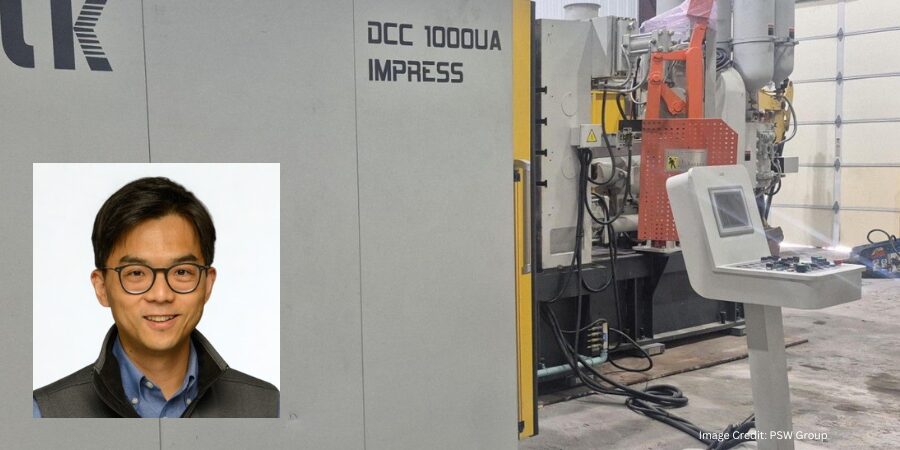

PSW Group announced the launch of its High Integrity Diecasting Center (HIDC) at the Magretech plant in Bellevue, Ohio, a new semi-solid casting center that enables clients to trial and optimize aluminum and magnesium castings with improved quality and structural integrity. The facility uses semi-solid and high-pressure die-casting technologies to support prototyping, process development, new product introduction, and pilot-to-production scaling for clients evaluating liquid and semi-solid casting processes. The investment places semi-solid casting R&D and engineering at the core of PSW’s strategy to accelerate low-carbon, high-integrity light metal innovation.

The new center features semi-solid casting technologies, including Comptech and Rheo-Structural Systems (RSS) for aluminum and Thixotropic Piston Injection (TPI) for magnesium. Notably, HIDC is one of the few semi-solid casting centers in North America offering both aluminum and magnesium semi-solid casting alongside conventional and structural high-pressure die-casting (HPDC).

Global Head of Products and Sustainability

PSW Group

“As clients demand lighter, stronger, and lower-carbon components, HIDC’s semi-solid platform unlocks quality, efficiency, and speed to market,” said Dr. Tao Wang, global head of Products and Sustainability at PSW Group. “By integrating advanced semi-solid technologies with our global R&D, we accelerate alloy development while reducing production emissions.” The HIDC gives original equipment manufacturers (OEMs), Tier 1 suppliers, and die casters the ability to trial, develop, test, and optimize new aluminum and magnesium alloys and evaluate casting technologies to determine the best combination for their specific products and applications.

“The HIDC enhances our U.S. manufacturing footprint and shortens time-to-market for next-generation components,” added Dr. Wang. It’s a pivotal step in our roadmap to low-carbon, high-integrity light metal systems.”

Press release is available in its original form here.