An HVAC manufacturer contracted a new controlled atmosphere brazing furnace. With this system, the company anticipates gains in both productivity and energy efficiency and reduction in their plant’s overall carbon footprint.

The contract for the system was awarded to SECO/WARWICK’s American subsidiary.

“Their manufacturing line is not a smooth, even flow of identical parts," remarked Marcus Lord, managing director at SECO/WARWICK USA, "Instead, part flow is intermittent and variable sizes. It is why we made the Active Only® CAB Furnace, to meet just such a demand.”

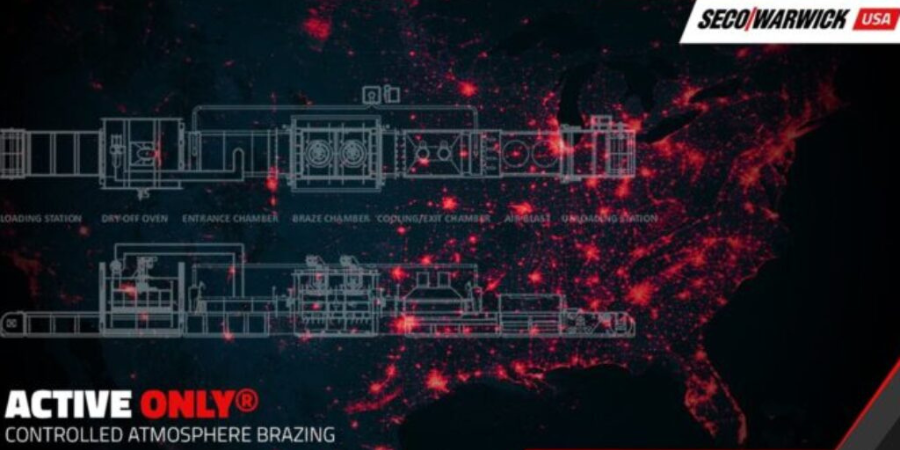

The operating sequence of the Active Only® CAB furnace is divided into stages, including: loading, drying in the dryer, nitrogen purging in the purging chamber, heating and brazing in a proprietary convection chamber, pre-cooling in the cooling chamber with an air-jacket, and the final direct air cooling in the final cooling chamber.

This semi-continuous furnace system will operate on a part-time basis; it will also allow for variable heating and cooling rates, depending on indexing times. Additionally, the furnace can braze the widest variety of heat exchangers when lower total production requirements are needed.