A Texas-based manufacturer of custom-built, match-grade rifles and performance parts for rifles and pistols recently announced that superior vacuum heat treatment capabilities result in the expansion of its line of parts for Steyr Arms Inc. A-1 pistols.

Ranger Point Precision, based near Houston, Texas, reported that their advanced heat treating process and salt bath black nitride allows for the conversion of any 40 S&W pistols to a .357 Sig, delivering match-grade accuracy, increased durability, reduced chamber friction, and extended barrel life. The expanded line includes both standard and threaded options along with thread protectors and mini-comps for .357 Sig / 9mm calibers.

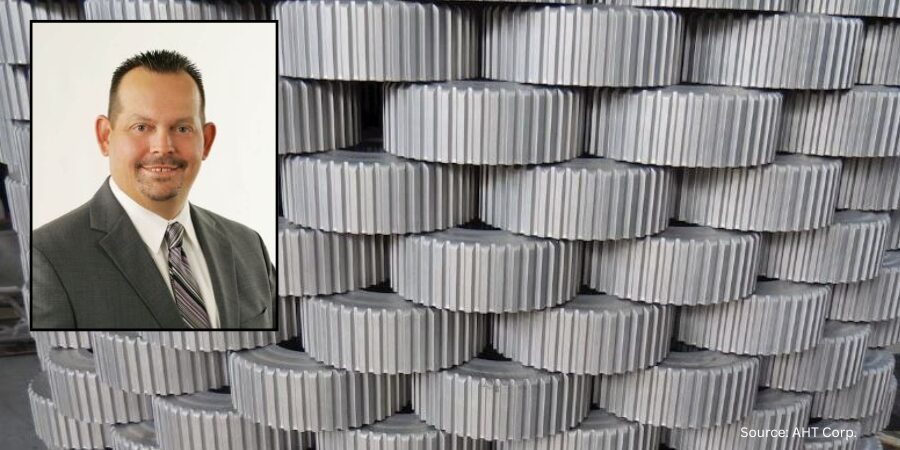

“We start with premium Douglas barrel blanks with precise rifling, then use minimum spec chamber reamers, and the most advanced methods for heat treating and salt bath black nitride to produce the best Steyr pistol barrel available on the market,” said Adam Devine, CEO, co-founder, and head of R&D, Ranger Point Precision.

Steyr .357 pistol barrels are vacuum heat treated to 42 HRC and salt bath black nitride coated, giving them a surface hardness above 80 HRC.