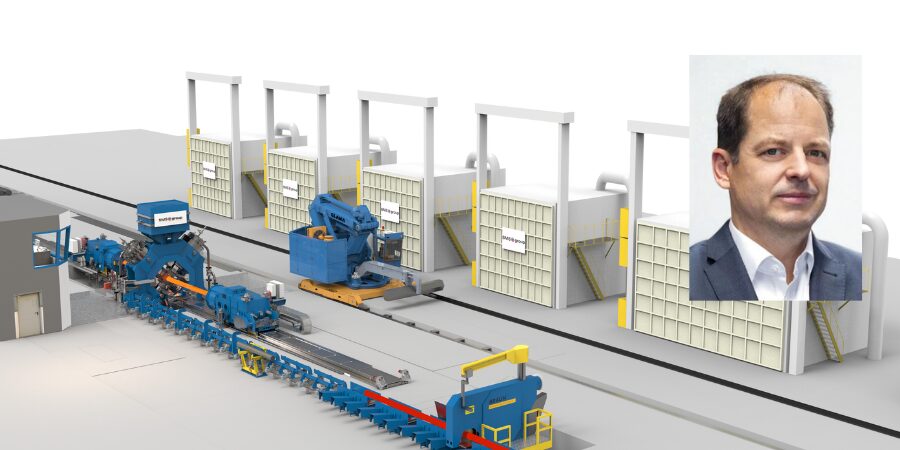

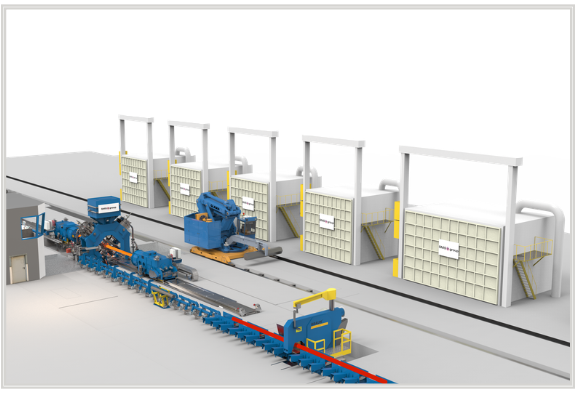

Haynes International Inc., has commissioned a new hydraulic radial forging line to increase its production of nickel- and cobalt-based alloys, serving markets such as aerospace and chemical processing in the United States. The integrated plant investment, which includes a forging machine, reheating and annealing systems, and automated material handling, is expected to improve production efficiency, metallurgical quality, and responsiveness to global demand while supporting growth in high-performance alloy manufacturing.

Slated for completion in 2027, the project features the SMX 800 / 25 MN hydraulic radial forging machine with a combined total pressing force of 100 MN, enabling direct conversion of ingots into billets and bars tailored for critical applications. The new line also incorporates cutting, loading, unloading, and bar finishing equipment to create a fully integrated solution that boosts throughput and supports advanced alloy processing.

Source: SMS group

Head of Forging Plants

SMS group

Supplied by SMS group, the radial forging line includes modern reheating and annealing furnaces designed to meet rigorous AMS 2750 temperature uniformity and tolerance standards, low-NOx burners to help maintain emissions below applicable environmental limits, and an integrated control system to manage production sequences with minimal operator intervention. Software tools, including Comforge®, will help optimize forging strategies based on real-time material behavior to improve yield and consistency.

At the core of the new capability is energy-efficient hydraulic technology that reduces installed electrical power requirements by roughly 50 percent while maintaining constant pressing force and precise process control. These features enable Haynes to deliver high-performance alloy products more efficiently while maintaining metallurgical quality to serve expanding needs in aerospace and other advanced industrial sectors.

Thomas Winterfeldt, head of forging plants at SMS group, said the project reflects a continued focus on pushing the limits of capability and efficiency in forging technology to meet material requirements in aerospace applications.

Press release is available in its original form here.