A heat treater in the U.S. Midwest anticipates greater heat treat abilities of ingots with a new gas-fired car bottom furnace. The furnace will be capable of handling both steel and aluminum ingots, with loads up to 150,000lb per cycle.

Vice President, Metal Furnaces

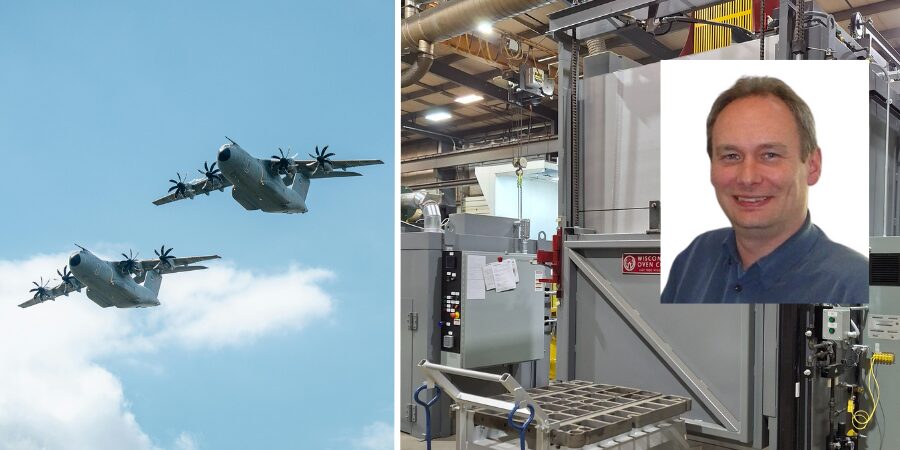

NUTEC Bickley

Source: NUTEC Bickley

NUTEC Bickley designed the furnace to operate across a wide temperature range. The high levels of temperature uniformity to be delivered by the combustion system mean that this furnace will be qualified to undertake AMS2750 compliant surveys.

Arturo Arechavaleta, NUTEC Bickley’s vice president of Metal Furnaces, said: “Our customer for this important project has been serving the industry with a dedicated heat treat facility for many decades, and is a widely recognized and trusted name in steel and aluminum circles.”

The working dimensions of the furnace are 12ft w. by 35ft l. by 14ft 6in h. Normal operational temperatures range between 300°F (150°C) and 1650°F (900°C), with a maximum of 2000°F (1095°C). With burners firing above and below the load, there are 11 automatic control zones (five top, six bottom). The optimum approach to heat treat these heavy loads is pulse firing with variable excess air.

The furnace uses high-velocity nozzle-mix burners in a staggered configuration to fire above and below the load, maximizing heat transfer and providing optimum temperature uniformity. One of the IMPS® (Integrated Multizone Pulsing System) modes is Excess Air Firing. Among other things, it allows control over very low temperature while high turbulence is maintained to achieve temperature distribution.

Source: NUTEC Bickley

Source: NUTEC Bickley

Source: NUTEC Bickley

In the Ratio Firing mode, the air and gas valves pulse in a synchronized pattern, from low to high fire in stoichiometric ratio, to ensure optimal fuel efficiency. This is made possible by using the kinetic energy generated by the flame speed and the rapid transition from low to high fire which increases entrainment and turbulence, thus promoting a better temperature distribution without the need for a high level of excess air.

Press release is available in its original form here.