In this Technical Tuesday installment, Kazunori Hokaku, business director/general manager/sales engineering dept. at Tokai Konetsu Kogyo shares the sustainability benefits of SiC heating elements.

This informative piece was first released in Heat Treat Today’s May 2025 Sustainable Heat Treat Technologies print edition.

In recent years, Silicon Carbide (SiC) heating elements have been increasingly used in demanding applications involving high temperatures and extreme atmospheres. Battery material manufacturing is one of many such applications. Therefore, improved service life contributes to increased productivity and sustainability as well as reduced industrial waste. This article discusses the long service life for recrystallized SiC heating elements having both excellent oxidation and corrosion resistance.

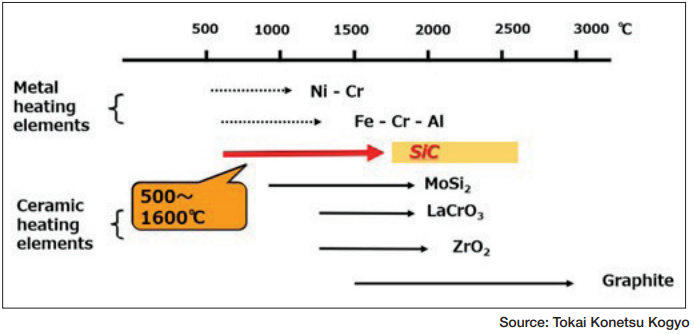

Tokai Konetsu Kogyo in Japan has been manufacturing EREMA® SiC heating elements since 1936. SiC heating elements are categorized as ceramic heating elements, which are widely used in a temperature range between 932°F–2912°F (500°C–1600°C) as shown in Figure 1.

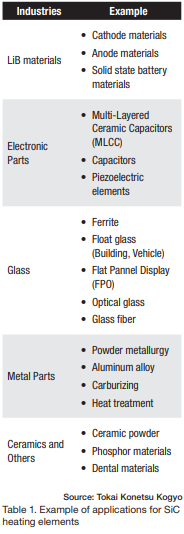

The heat value per unit area (i.e., watt density) of SiC heating elements is quite high, 5 to 10 times that of metallic Nichrome wire heating elements, for example. SiC heating elements are chemically stable and an environmentally friendly source, free of air and noise pollution compared to gas-fired or liquid fuel systems. As such, they are chosen and used for a variety of applications, such as Lithium-ion battery material (i.e., cathode/anode/solid state battery materials), powder metallurgy, aluminum, hardening and case hardening applications (e.g., carburizing), electronic parts (MLCC, ferrite), and dental materials as shown in Table 1.

SiC heating elements come in a variety of shapes, namely straight rod, U-shaped, and W-shaped designs. They are affordable and easy to handle compared to other ceramic heating elements. It is important to remember, however, that their service life is drastically influenced by high temperatures and the atmosphere.

The failure mechanism of a SiC heating element to its service life is shown in Figure 2. SiC reacts with O2 and creates SiO2, by which the resistance of the heating element increases.

Therefore, increasing bulk density and reducing specific surface area are key to service life longevity. This relationship between bulk density and service life in alkaline atmosphere (Li2CO3) has been explored by Tokai Konetsu Kogyo using scanning electron microscopy (SEM) photos with results as shown in Figure 3.

Silicon Carbide 101

■ Electric heating elements are a popular choice of many heat treaters. They come in a variety of shapes, sizes, and materials. One of the most common types are silicon carbide (SiC) heating elements, known by several tradenames including Globar™ and StarBar™. They are used extensively throughout the heat treating industry when high temperatures, maximum power, and heavy duty cycles are required.

A SiC heating element is typically, but not always, an extruded tubular rod or cylinder made from high purity grains of silicon carbide that are fused together by either a reaction bonding process or a recrystallization process at temperatures in excess of 3900°F (2150°C). The result is a chemically stable material with a low thermal expansion coefficient and little tendency to deform.

Recrystallization forms fine grains of silicon carbide that act as “bridges” or connection points between larger grains thus forming conductive pathways. The number of bridges formed dictates the material’s resistance: the greater the number, the lower the resistance. The secret to the creation of a good heating element is controlling this formation process within the material to develop a consistent electrical resistance

The factors that influence the life of a SiC heating element include the type of furnace atmosphere, watt density, operating temperature, type of service (continuous or intermittent), and maintenance. Furnace type, design, and loading play an important role as well. SiC heating elements are extremely versatile operating, for example, in air up to 3000°F (1650°C).

Finally, the choice of heating element depends on many factors. For example, SiC heating elements are capable of higher operating temperatures and higher watt loadings than say metallic elements; they are self-supporting and can be used in furnaces either too wide or too long to be spanned by other element types and are relatively easy to change while hot. SiC heating elements are used extensively in brazing and sintering furnaces running continuously at or above 2050°F (1120°C) and for other processes where the temperature range lies between 2375°F (1300°C) and 2725°F (1500°C).

With permission from the author, Dan Herring, the information cited has been used in part from, Herring, Daniel H. “Electric Heating Elements Part One: Silicon Carbide.” Industrial Heating, September 2008. ■

SEM photos show the Sustainable Development Goals (SDGs) model observed increased bulk density with low porosity and very thick neck growth of SiC grains. The specific surface area for the SDGs model of 0.03 m2/g by Brunauer–Emmett–Teller (BET) method is smaller than that of the standard high-density grade of 0.05 m2/g.

As a result, the graph in Figure 3 shows that the service life for the EREMA®SDGs model (BD = 2.65) is the longest, which means a reduction not only in downtime of furnace operation but also of industrial waste.

About The Author:

Business Director/General Manager/Sales Engineering Dept

Tokai Konetsu Kogyo

Kazunori Hokaku graduated from Kyoto Institute of Technology in 1985 with a major in ceramics. He has been with Tokai Konetsu Kogyo Co., Ltd., since 1985 and is currently the business director/general manager/sales engineering dept.

For more information: Contact Kazunori Hokaku at k.hokaku@tokaikonetsu.co.jp