Vacuum Brazing, Quench and Temper Furnaces Part of Heat Treat Expansion

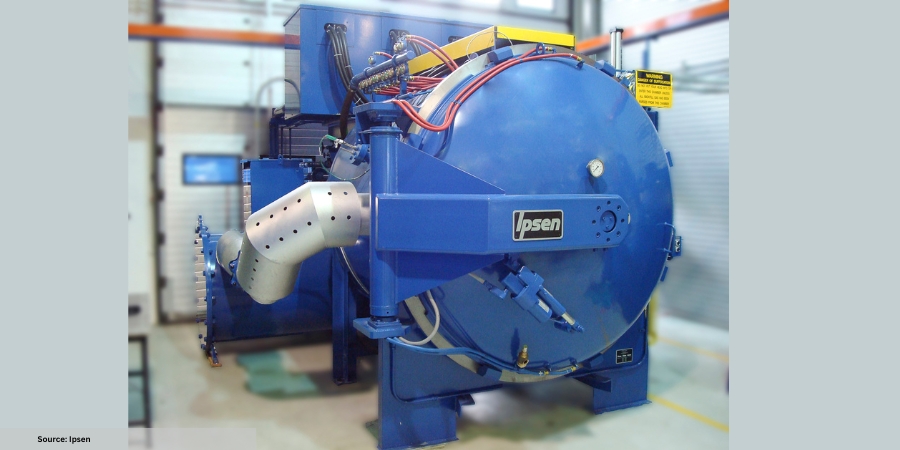

A Polish heat treatment provider recently announced the startup of vacuum brazing processes at its newest plant in Kalisz for the power generation and aerospace industry. The new facility houses vacuum furnaces as well as borescopes, spectrometer, welding systems, hardness testers, selective plating equipment and a sandblasting cabinet.

In addition, Hauck Heat Treatment has invested in the installation of new heat treatment equipment at their Dzierżoniów location, including new sealed quench furnaces (batch size 910mm x 760mm x 1220mm), one tempering furnace and one endogas generator.

The company also reported that its services to the Eastern European market have expanded with the addition of thermo-chemical treatment, carbonitriding.

Vacuum Brazing, Quench and Temper Furnaces Part of Heat Treat Expansion Read More »