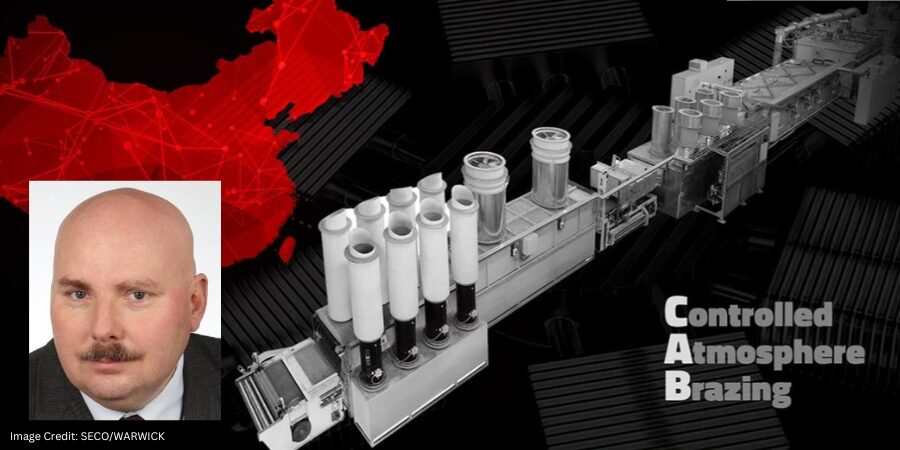

An automotive manufacturer is expanding stainless steel brazing capacity at its Midwest manufacturing facility, adding a new 24-inch belt, four-zone brazing furnace. The system will support increased production of automotive components, including braking and fluid line parts, where consistent thermal processing and atmosphere control are essential to quality and reliability.

Designed for controlled-atmosphere processing, the furnace will operate in a nitrogen/hydrogen environment and is engineered to deliver repeatable results, stable production flow, and operator-friendly performance.

Executive Vice President, Sales & Marketing

Gasbarre Thermal Processing Systems

The order marks the company’s third brazing furnace supplied by Gasbarre Thermal Processing Systems, building on two existing installations currently supporting day-to-day operations. The equipment was selected based on the design and performance of prior systems, which have delivered dependable uptime with minimal issues while maintaining a clean, accessible layout that operators find easy to use — a key factor in a high-output environment.

“This order reflects the trust we work to earn through durable equipment, repeatable processing, and responsive support,” said Ben Gasbarre, executive vice president of sales and marketing at Gasbarre Thermal Processing Systems.

Press release is available in its original form here.