Heat Treat Today is pleased to welcome this regular column spot, Answers in the Atmosphere, to David (Dave) Wolff, an independent expert focusing on industrial atmospheres for heat treat applications. This column explores various atmospheres with Dave and different industry specialists.

This informative piece on the critical role of atmosphere control in metal thermal processing was first released in Heat Treat Today’s October 2025 Ferrous & NonFerrous Heat Treatments/Mill Processing print edition.

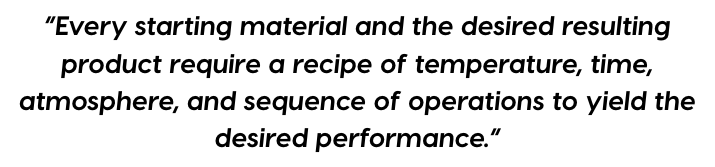

Thermal processing of metals is critical to successful production of fabricated metal parts and assembled systems. Characteristics of parts and devices, including blades, springs, wire and cable, medical implants, and electric motors, all depend on successful thermal processing to produce metallic components with specific properties to meet the requirements of the part, assembly, or device. What is sometimes overlooked, however, is that atmosphere is as critical as the heat itself. The wrong furnace atmosphere can undo the best processing recipe, while the right one ensures that parts achieve their intended properties consistently.

Tune into the news, and you will find stories about metal parts incorrectly handled during thermal processing: gears that degrade to powder, camshafts that were too soft, electric switches that fail, materials with the wrong magnetic properties, knives that cannot hold an edge, and so on. These are all problems that occur too frequently and are expensive to resolve, because metal parts are often components in a more complex and expensive assembly. (Imagine the responsibility of parts-making for military jet engines or body-implanted parts. You do not want to be the shop supplying inadequate parts!) It is imperative that heat treating and sintering processes are completed correctly the first time.

Metals thermal processing requires more than just heat. As indicated above, atmosphere is essential to the heat treating process, coming alongside temperature, time, and a specific sequence of operations in a recipe that will ensure the material yields the desired performance. Much like baking bread, thermal processing of metals requires equipment, materials, conditions, and recipes. The furnace is the main equipment (other operations may be performed in a less expensive thermal processing oven). Then there are the materials — the parts being heat treated — which may be bulk metals, alloys, or compacted powder parts with unique blends and surface morphology. The conditions of time, temperature, atmospheres, and perhaps a quenching step come together in a specified recipe. Properly done, heat treating and sintering operations will yield parts that meet the hardness, toughness, appearance, surface finish, shape, dimensions, and other specialized and specified properties.

Since cost is an important driver, metals thermal processors strive to produce compliant parts in as few steps as possible. Innovations can assist in making it possible to consolidate steps, too. But mistakes in thermal processing may result in defective parts or require expensive rework or even additional (secondary) operations to correct deficiencies.

Each issue, this column will focus on the atmospheres component of heat treating. You’ll read interviews with industry experts focused on the atmospheres used in thermal processing — from relatively inert atmospheres, such as vacuum, nitrogen, and argon, to chemically active atmospheres used for annealing, hardening, and sintering. We will assist thermal processors by explaining how various atmospheres work, what the key properties are that determine successful results, how to buy and utilize the atmospheres, and precautions and alternatives for that atmosphere.

My hope is that this column will help Heat Treat Today readers become better buyers and users of atmospheres, so that you can run a smoother, more reliable, and more profitable operation.

About The Author:

Independent expert focusing on industrial atmospheres for heat treat applications

Dave Wolff has over 40 years of project engineering, industrial gas generation and application engineering, marketing, and sales experience. Dave holds a degree in engineering science from Dartmouth College. Currently, he consults in the areas of industrial gas and chemical new product development and commercial introduction, as well as market development and selling practices.

For more information: Contact Dave Wolff at Wolff-eng@icloud.com.