An international, multi-billion-dollar corporation at the forefront of drivetrain technologies has commissioned a complete isothermal annealing line, due to be delivered in Q1 2026. The furnaces are designed to be in compliance with CQI-9, the comprehensive audit covering the most common heat treat processes employed by the automotive industry. This investment underscores the automotive industry’s commitment to delivering higher-quality components while meeting stringent manufacturing standards.

Vice President, Metal Furnaces, NUTEC Bickley

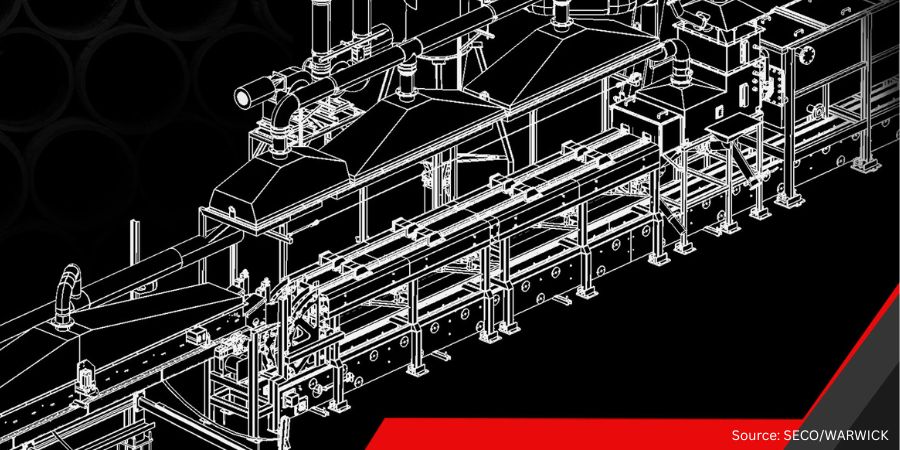

The system has been designed in close collaboration with NUTEC Bickley to ensure everything meets the company’s specific operational needs. The contract comprises both high-temperature and low-temperature furnaces, as well as an isothermal cooling chamber and blast cooling tunnel, together with all the ancillary equipment and full material handling and conveying system.

Arturo Arechavaleta, VP Metal Furnaces at NUTEC Bickley, said: “Our client for this multifaceted project is an auto component world leader that supplies nearly every major vehicle manufacturer. It has an established reputation in delivering high quality parts and promoting sustainability in the supply chain. I am delighted the NUTEC Bickley was chosen to partner in the design and manufacture of this isothermal annealing line.”

At the heart of the new facility will be a double pusher tray high-temperature furnace (HTF) designed specifically for processing carbon steel automotive parts. The system incorporates a fully automatic electrical double pusher system with steel trays sliding over rails with idle rolls. Processing two trays across the width helps reduce the line’s footprint while maximizing throughput.

The natural gas unit features four automatic temperature zones, each with two high-velocity nozzle-mix burners that provide excellent turbulence and outstanding recirculation within the furnace chamber. Operating temperatures range between 850°C and 950°C (1560°F-1740°F), with temperature uniformity targets of ±5°C (±40°F) for processes below 680°C (1260°F) and ±10°C (±18°F) at or above 680°C (1260°F).

The isothermal annealing process involves multiple stages that work in seamless coordination.

First, forged carbon steel parts move into an isothermal cooling chamber (ICC) after initial heat treating where the load temperature is rapidly reduced from 950°C (1740°F) to 660°C (1220°F) within five to 10 minutes, bringing parts to their transformation point. This rapid cooling uses ambient air supplied from an external cooling fan.

Then, parts proceed to a low-temperature furnace (LTF) operating at between 630°C and 700°C (1170°F-1290°F), which uses a fuel-only control system for enhanced temperature uniformity. The furnace relies on three automatic temperature control zones and six burners.

Finally, tray loads pass through a blast cooling tunnel (BCT) where forced convection cooling with ambient air brings parts down to approximately 400°C (750°F) before exit.

The complete line includes comprehensive material handling and conveying systems that operate fully automatically. It features entrance and transfer cars with movement systems, transfer car tracks, exit transfer cars with tray dumper units, integrated air cooling units, return conveyors with electrical dolly systems, and automated loading stations. The entire parts handling system is linked to the process via Master PLC and HMI for seamless operation.

Press release is available in its original form here.