Sustainability pressures are reshaping heat treating as aerospace and automotive suppliers across North America face growing demands to reduce the carbon footprint of thermal processing. Lower-emission operations are increasingly influencing customer decisions, with companies seeking partners who can help meet bold decarbonization targets. Against that backdrop, Bodycote has reached a zero-emissions milestone that highlights how decarbonized heat treating can be achieved at scale.

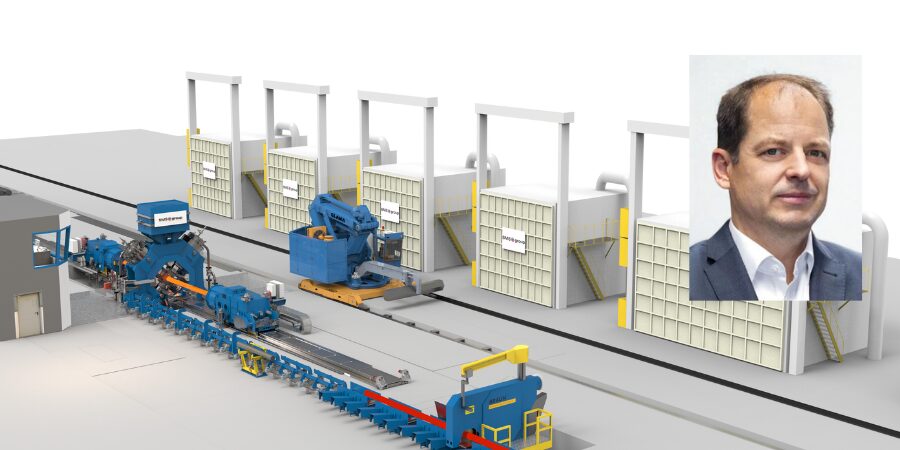

CEO

Bodycote

Source: Bodycote

The milestone was achieved at Bodycote’s Derby and Rotherham heat treatment facilities in the United Kingdom, which now operate with zero direct carbon emissions. The plants, which specialize in heat treating turbine blades for Rolls-Royce jet engines, are fully electric and powered by 100 percent renewable electricity, eliminating the need for fossil fuels or carbon offsetting.

“Our customers, many with ambitious 2030 targets, are looking for suppliers who can support their decarbonization efforts. Recently, a customer with a 90% carbon reduction goal came to us because of the impact offered by our lower-carbon thermal processing. These are real demands, and the clock is ticking,” said Jim Fairbairn, CEO of Bodycote. The development reflects broader efforts to address industrial energy use while maintaining process reliability for demanding applications.

Bodycote’s transition to zero emissions is achieved through investment in industrial heat electrification, energy efficiency, and renewable energy sourcing. A new closed-circuit adiabatic cooling system was recently introduced at the Derby plant, located alongside the Rolls-Royce site. Replacing evaporative cooling towers, this installation delivers electricity consumption savings — including peak-load reductions — of 73%, cuts water usage by more than 85%, and avoids the need for chemical dosing and cleaning.

“For Bodycote, leading in this space is not only the right thing for the planet, but also the right thing for our global business,” said Fairbairn. “As well as the progress made in Derby and Rotherham, we are running pilot decarbonization projects across Europe and North America.”

Those pilot efforts are intended to inform broader adoption across the company’s global footprint, including North American facilities serving aerospace, automotive, and other demanding markets. By sharing best practices and scaling proven technologies, Bodycote aims to support customer sustainability goals while maintaining quality, consistency, and process reliability.

Press release is available in its original form here. Additional information provided by Bodycote.