Heat Treat E-Commerce: A Growing Trend or a Passing Fad?

![]() E-commerce? In the heat treating industry? Heat Treat Today was curious about this new trend, so we asked three heat treat insiders about their industry e-commerce experiences. Is e-commerce coming to the industry? Where has it succeeded; where has it failed? Is e-commerce a growing trend or is it just a passing fad? Find out if your future will include heat treat e-commerce or not!

E-commerce? In the heat treating industry? Heat Treat Today was curious about this new trend, so we asked three heat treat insiders about their industry e-commerce experiences. Is e-commerce coming to the industry? Where has it succeeded; where has it failed? Is e-commerce a growing trend or is it just a passing fad? Find out if your future will include heat treat e-commerce or not!

Contributors include Shawn Orr, engineering manager, and Jonathan Lance, senior marketing specialist, at Televac®—The Fredericks Company and Clint Hall, the vice president of Marketing at Olsträd Engineering Corporation and Combustion 911.

Introduction

CBRE Group, Inc., an American commercial real estate services and investment firm, projects that U.S. e-commerce sales will increase $330 billion between 2020 and 2025. Others, like market research firm Statista, project an increase by about one-third.1 This may be the case for industry in general, but are purchasing habits of heat treaters changing, too? Could “e-commerce” be the next big thing for heat treaters?

We asked several heat treat industry insiders what they thought e-commerce could offer to heat treaters and how this service addresses a variety of purchasing needs.

What is “E-Commerce”?

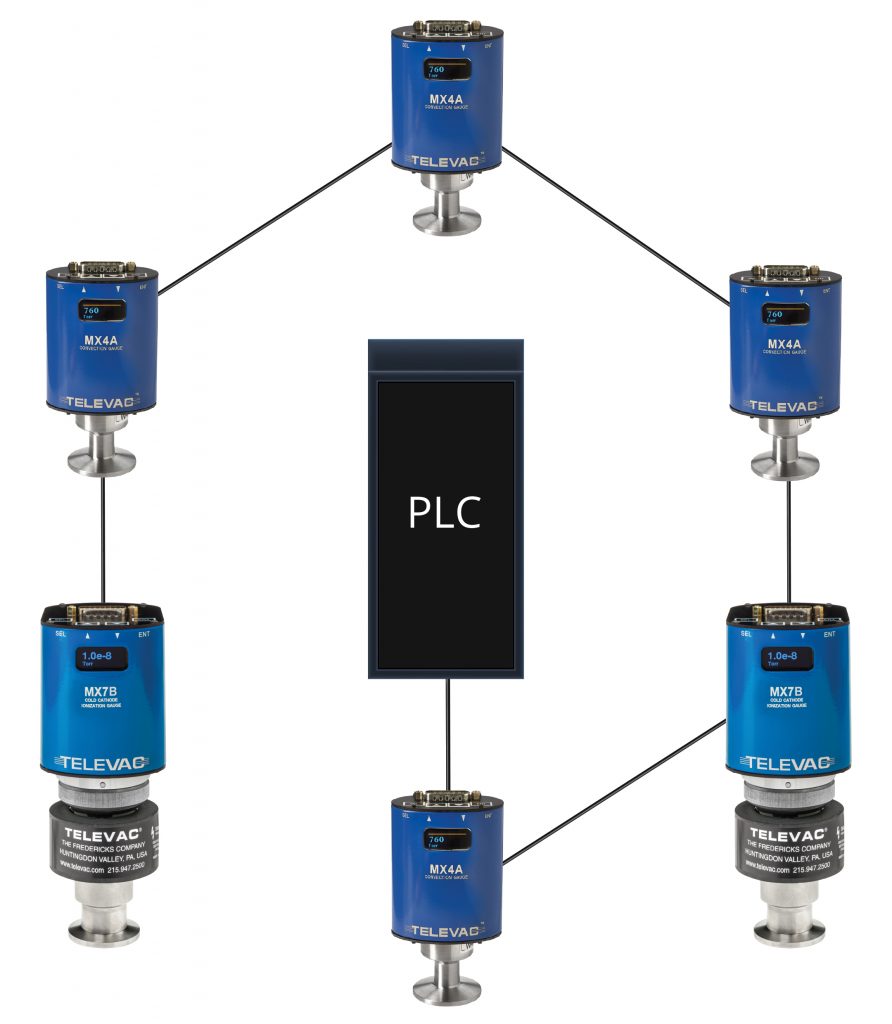

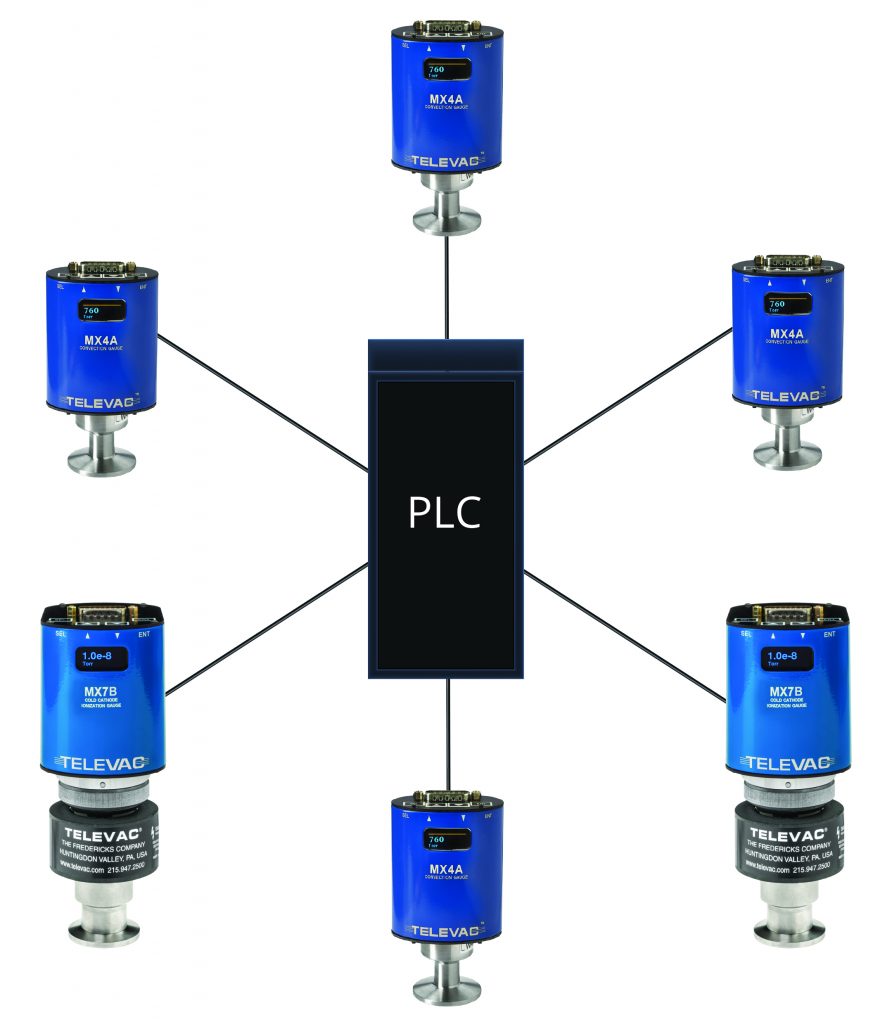

Shawn Orr & Jonathan Lance: “Televac® is a designer and manufacturer of vacuum gauges, so to us e-commerce means offering our products for sale through our website and making them as easy as possible to purchase with the shortest possible lead times. Having online pricing and the ability to order online eliminates any lag time associated with waiting for a quote, email, or call from one of our sales representatives.”

Clint Hall: “We view e-commerce as (spare) part sales via the internet. We sell combustion equipment heat treaters use to keep their furnaces running.” Hall represents Olsträd Engineering Corporation’s Combustion 911 service.

Engineering Manager

Televac®—The Fredericks Company

Photo Credit: The Fredericks Company

Senior Marketing Specialist

Televac®—The Fredericks Company

Photo Credit: The Fredericks Company

Vice President of Marketing

Olsträd Engineering Corporation and Combustion 911

Photo Credit: Olsträd Engineering

[accordion style="colored"][acc title="Televac®—The Fredericks Company"]Televac® serves the heat treat industry by providing low-cost, robust, full range vacuum gauging solutions. With Televac®’s new e-commerce website, they are able to reduce lead times, while providing the same high-quality products, services, and support. [/acc][acc title="Combustion 911"]Combustion 911 is an e-commerce website which serves the heat treat industry by providing spare parts, but also complete combustion systems. Heat treaters use combustion systems to safely transport combustible fuels.[/acc][/accordion]

Getting on the Cutting Edge

These insiders shared that their initiative to implement e-commerce for heat treaters largely came from looking at the growing use of web retail in other manufacturing and service industries. They also elaborated on several practical lessons that come with spearheading a web-based, transactional initiative.

Hall: “We started Combustion 911 in 2009. We saw companies like Amazon and Walmart create a space for retail on the web, and we reasoned we could do the same thing for combustion parts. Our initial thought was to create and maintain a space where maintenance staff could easily source parts using a purchasing card, removing barriers and red tape that might keep them from getting the part quickly.”

When asked about lessons he and his team learned, he shared, “The lessons we learned were many and varied. For example, our first lesson was the need to include our phone number on the website. We thought this was going to be hands-off for us, and we were dead wrong. There are a lot of people in the world who don’t trust online shopping carts and will not use them. There are also a lot of people working with combustion equipment who need some reassurance they’re buying the right replacement part, and they’d rather speak on the phone than hash it out over email.

Second, we learned there aren’t nearly as many maintenance folks out there with purchasing cards (p-cards) as we’d thought. Most of our Combustion 911 transactions go through purchasing staff or third-party buyers.”

They continued, “Building e-commerce functionality into an existing website wasn’t always an easy task. It was a challenge to maintain the look and feel of our website while also offering a streamlined e-commerce experience for our clients. One of the major takeaways was that it isn’t always about making an online sale, but instead it’s about maintaining quick access to the resources that our website offers to clients, like datasheets, manuals, application notes, instructional videos, and interactive tools, among others.”

The Evidence: How E-Commerce Helps Heat Treaters

Orr & Lance: “There are many instances where we’ve seen our e-commerce website help our clients. One specific example was when a client needed 8 of our 2A thermocouple vacuum gauges to ship the same day because they had a system down. They were able to place the order on our website within minutes of realizing their need and make a payment that was processed immediately, allowing us to quickly receive the order and ship out the gauges the same day.

“We’ve also found that our e-commerce website significantly reduces the amount of time and effort required for our clients to place an order. An online order eliminates multiple emails or phone calls between our clients and the team, and streamlines the payment process. Because of these improvements, we can often reduce our lead times by several days, getting our products to our clients faster.

Photo Credit: The Fredericks Company

Hall: “The combustion market has been going through an upheaval due to the consolidation and eradication of many legacy brands. End users find themselves in a position where they need replacements for parts that have been discontinued or aren’t immediately available. We’ve been able to help users get back up and running using alternative parts with the same function, from stock.

“Additionally, e-commerce gives us a chance to reach a wider audience, which means we can help those in need find the assistance they’re looking for. It takes sustained effort to be relevant on the web, but the result is higher visibility, and the rewards are of equal benefit to us and our clients. They get the help they need, and you get the opportunity to serve them.”

The “Preferred” Purchasing Method

All three insiders attest to the ease-of-use for their clients. Whether it is measured in increased traffic to their website or how the tool has become the preferred purchasing method.

Hall: “Combustion 911 has been going strong since its inception (and once we added our phone number). An unlooked-for boon in this website has been the generation of leads for system sales. We offer combustion and automation engineering, suites of parts, assembled manifolds, control panels, installation, service, the works. These services are available piecemeal or all together, and we’ve developed long-term clients from Combustion 911 inquiries in every category.”

Orr & Lance: “Since we launched our e-commerce website in 2020, we have seen a significant increase in online orders each month from clients purchasing our vacuum gauging. We’ve found that many of our clients prefer purchasing online because they want the same experience they have with other online retailers.”

Final Thoughts

Perhaps you are on the frontier of either purchasing or selling heat treat equipment, parts, or services online. As has been discussed, streamlining purchasing habits, finding a new heat treat product provider, or being able to “click” the most up-to-date product with quick shipment options are all appealing reasons to try e-commerce. But as with any change or innovation: Do your research to make sure that this service is right for you before you dive headfirst. Happy buying!

References

1 David Sparkman, “Industrial Real Estate Demand Rising,” Material Handling & Logistics (7 July 2021). www.mhlnews.com.

About the Authors:

Shawn Orr, engineering manager at Televac®—The Fredericks Company, is responsible for the company’s engineering department and all engineering projects related to research and development and manufacturing.

Jonathan Lance, senior marketing specialist at Televac®—The Fredericks Company, is responsible for addressing all marketing needs for the company, including website development, graphic design, digital advertising, and analytics.

Clint Hall is the vice president of Marketing at Olsträd Engineering and Combustion 911. Olsträd provides advanced combustion, controls, and automation systems across a broad spectrum of industries, and represents ESA (burners, flame safety, combustion solutions) and Elektrogas (combustion controls) in North America.

Heat Treat E-Commerce: A Growing Trend or a Passing Fad? Read More »