EthernetIP is the future of vacuum gauge communications for vacuum furnaces. It’s simple to integrate and improves accuracy by reducing latency from legacy analog 0 to 10 V DC outputs.

Televac – The Fredericks Company

Learn about EthernetIP and its place in your heat treat department in this Technical Tuesday original Heat Treat Today article by Shawn Orr, Technical Business Development manager with Televac – The Fredericks Company.

This article first appeared in the latest edition (March 2020) of Heat Treat Today’s Aerospace Heat Treating magazine.

What is EthernetIP?

EthernetIP (IP for Industrial Protocol) is an implementation of the digital communication standard referred to as the Common Industrial Protocol (CIP). It’s a modification of standard Ethernet and is managed by the organization ODVA, Inc. If you’re familiar with the OSI model (Open Systems Interconnection), EthernetIP defines the session layer, the presentation layer, and the application layer, with the other layers (1 through 4) defined by standard Ethernet.

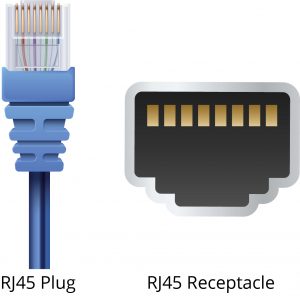

EthernetIP uses standard RJ45 connectors (Figure 1) which are 8P8C (8 position 8 contact). The widespread use and availability of standard Ethernet cables makes them a more affordable solution compared to custom cables and connectors used by many manufacturers for their devices.

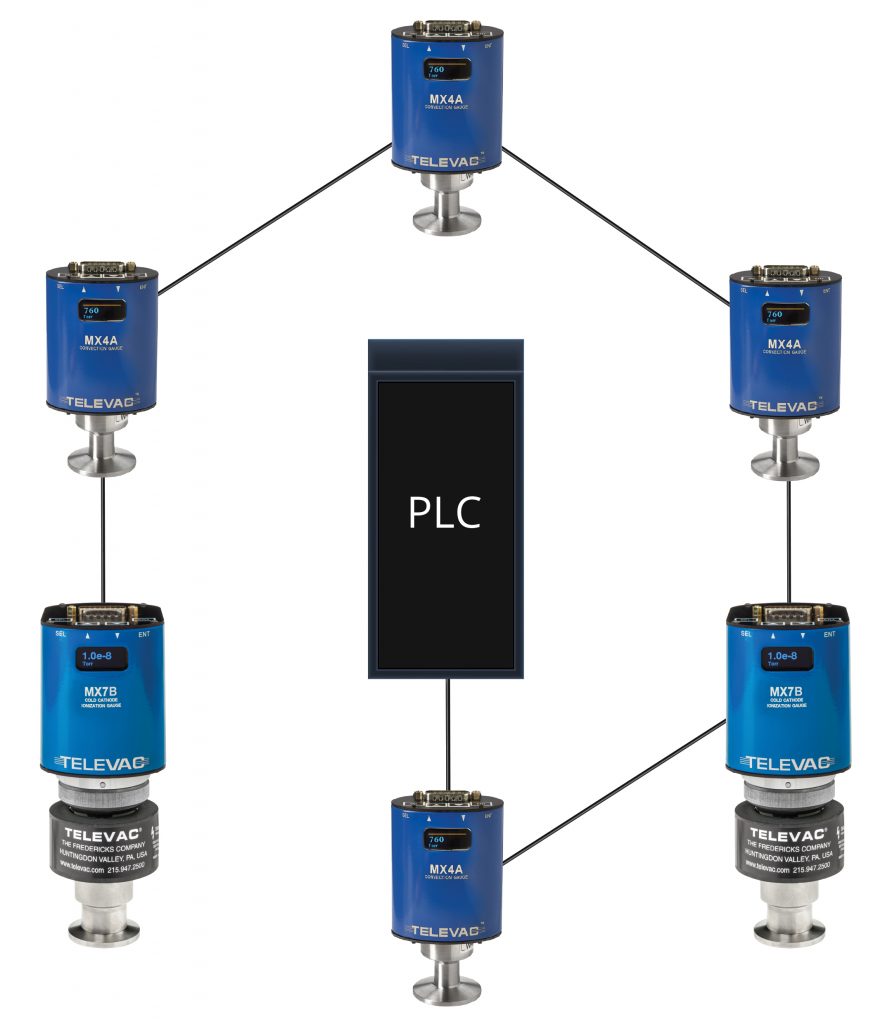

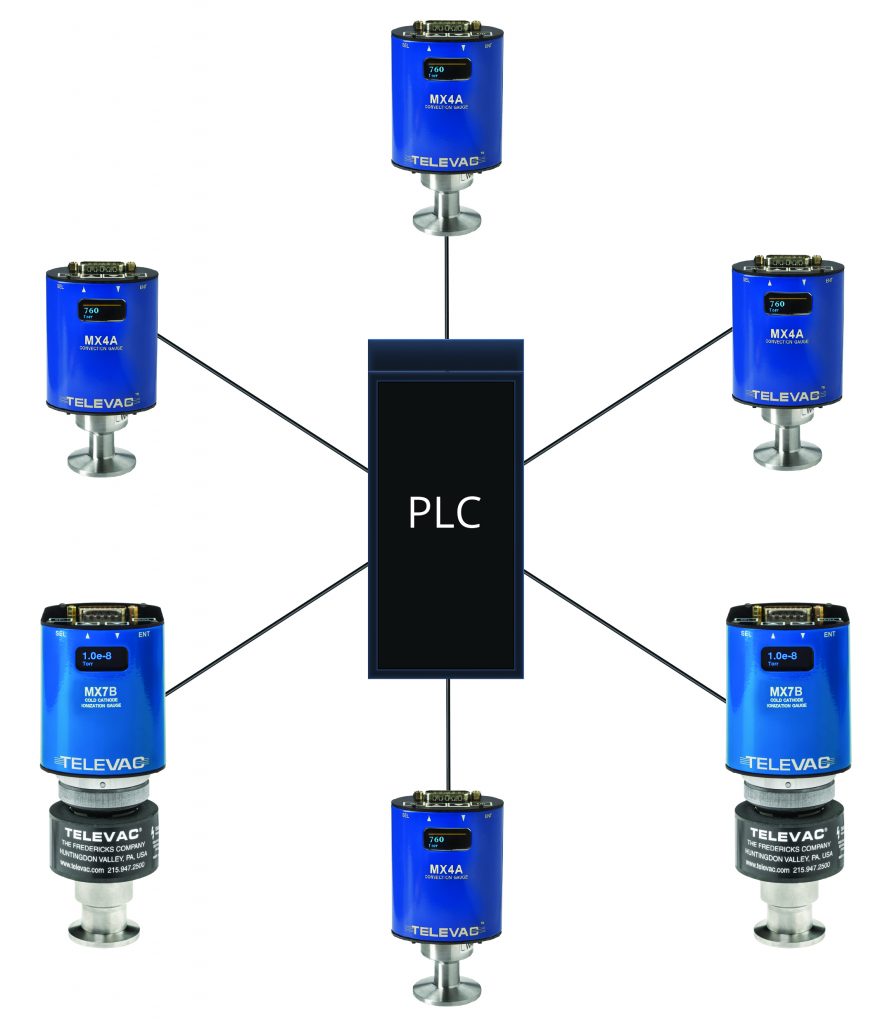

EthernetIP can be configured with various topologies including ring (daisy chaining) and star (point-to-point) configurations (Figures 1 & 2). This can further reduce integration complexity and cable complexity by daisy chaining various components together on the same EthernetIP connection. Each device will have a unique IP address (or they can be grouped together in some cases depending on the implementation), but all configurations will allow you to communicate with all devices individually and digitally.

Communications are done in one of two ways; cyclically (Class 1 EthernetIP connection) and acyclically (Class 3 EthernetIP connection). Cyclic communications output the same set of data over and over at a specific rate. Acyclic communications allow you to send commands and receive data back from the EthernetIP device at any time. Acyclic communications give you more control, but cyclic communications can be simpler to integrate.

How Does It Apply to Heat Treating?

So, you might be wondering, how does this apply to vacuum furnaces? All vacuum furnaces have a PLC (programmable logic controller) which is essentially the brain of the furnace. In North America, one of the most common types of PLCs is a Rockwell Automation® Allen-Bradley® PLC which has, you guessed it, EthernetIP capability! PLCs almost always have an HMI (human machine interface) where the operator can control various functions of the furnace.

The PLC takes a variety of inputs from other controllers and sensors which come in many shapes and forms. Some of the most basic are analog signals like 0 to 5 V DC or 0 to 10 V DC. Others are more complex forms of digital communication like EthernetIP. This means that you can use your PLC and HMI to take readings and adjust settings on connected EthernetIP devices.

What Are the Benefits of EthernetIP?

We already talked about some benefits of EthernetIP, but there are many others. Another significant benefit is having digital communications to your vacuum gauging and other devices on the furnace. Let’s use the example of vacuum gauge calibration.

Benefit 1 – Calibration

Many who have worked with devices on vacuum furnaces like vacuum gauges know that calibrating them can be a real hassle. Gauges often have potentiometers (sometimes called pots) that are adjusted with a set screw. This means that you’re trying to look at one reading on the HMI of your furnace while adjusting a gauge that’s possibly on top of the furnace, meaning you need two people. This is a worst-case scenario, but you get the idea; it’s not convenient.

Having digital communications over EthernetIP means that your calibration can be done from the HMI, because you can adjust the calibration digitally with most digital vacuum gauges. No more climbing on top of the furnace and adjusting pots! This is especially useful as Nadcap and AMS (specifically AMS 2769) standards become stricter, you may want to start doing more calibration at your facility instead of sending your gauges out to another facility for calibration.

Benefit 2 – Cost

One of the most significant benefits is the cost of using EthernetIP enabled devices. In addition to cheaper standard Ethernet cables, most furnaces will include other devices with EthernetIP capability, so an EthernetIP communications module for the PLC is already included. This means that if you have analog devices (such as 0 to 5 or 10 V DC), you can remove the need for costly ADC (analog to digital converter) modules by switching your devices to EthernetIP.

Benefit 3 – Power

Another benefit is powering your devices. Because there are open pins on a standard Ethernet cable with standard EthernetIP connections, it’s possible to utilize the unused pins to supply power over the Ethernet cable. There are other implementations where the power is supplied over the data lines. This is called PoE (Power over Ethernet). This eliminates the need for additional, potentially costly and complex power connections for your EthernetIP enabled devices. PoE is done many different ways, but three have been standardized by IEEE called Alternative A, Alternative B, and 4PPoE.

Benefit 4 – Accuracy

The last benefit is accuracy. Using an analog signal can cause signal loss and is susceptible to signal degradation from noise depending on the cable length, particularly in industrial environments. The speed of an analog to digital conversion is also typically done with an equation and can be slow and somewhat inaccurate for a variety of reasons. Eliminating analog to digital conversions improves the latency and accuracy of readings on your HMI. No more mismatches between your gauge display and your vacuum furnace HMI!

How Do You Integrate EthernetIP into an Existing System?

Talk to your furnace manufacturer or a system integrator. First, you’ll need to make sure you have an EthernetIP enabled PLC, then you’ll need to make sure that your furnace configuration supports the addition of specific EthernetIP devices. Since each type of device communicates differently over EthernetIP, you may need to have PLC code and HMI changes made to your system to support something like an EthernetIP vacuum gauge.

About the Author: Shawn Orr is the technical business development manager for Televac – The Fredericks Company and has served as the technical liaison between its customers and engineering, responsible for identifying and implementing new growth opportunities.

(Photo Source: Figures 1-3: Televac – The Fredericks Company)