AI is moving from concept to practice in heat treating — driving furnace optimization, smarter scheduling, and predictive compliance. In this Q&A, Peter Sherwin, strategic marketing at Watlow, highlights how Model Context Protocol (MCP) will connect data, tools, and operators to reshape the industry’s digital future.

This informative piece was first released in Heat Treat Today’s October 2025 Ferrous & Nonferrous Heat Treatments/Mill Processing print edition.

Q1. What do we mean by “AI” in industrial heat treat?

It is probably best to start with a contrast. We have fixed code in heat treat applications, such as a setpoint programmer that is pre-programmed with ramps and soaks at specific temperatures for specific times. I like to think of AI (artificial intelligence) as introducing the concept of flexible code that learns from data over time.

AI has been used for a surprisingly long time in heat treatment. The original autotune algorithms used a form of AI and machine learning to adapt the PID parameters to a specific furnace, learning from real equipment process signals (such as temperature sensors) to provide optimum control.

Q2. Where is AI already working in heat treat?

AI is most obviously used in equipment optimization, and there are a growing number of cases expanding from process control to energy optimization. Less obvious uses are within the heat treating plants. For example, AI in contract review can highlight key customer requirements, pull together relevant specifications, and help craft recipe design or selection.

A common issue across plants is the need to continually optimize and re-optimize production planning and scheduling. Because heat treating occurs near the end of the manufacturing chain, last-minute changes are common. The ability to quickly re-plan based on specific requirements is a typical use of AI.

Following the process, quality analysis is now supported by AI with optical microscopy that leverages microstructural datasets. AI can also be used for financial analysis, recruitment, and customer support.

Q3. What is MCP?

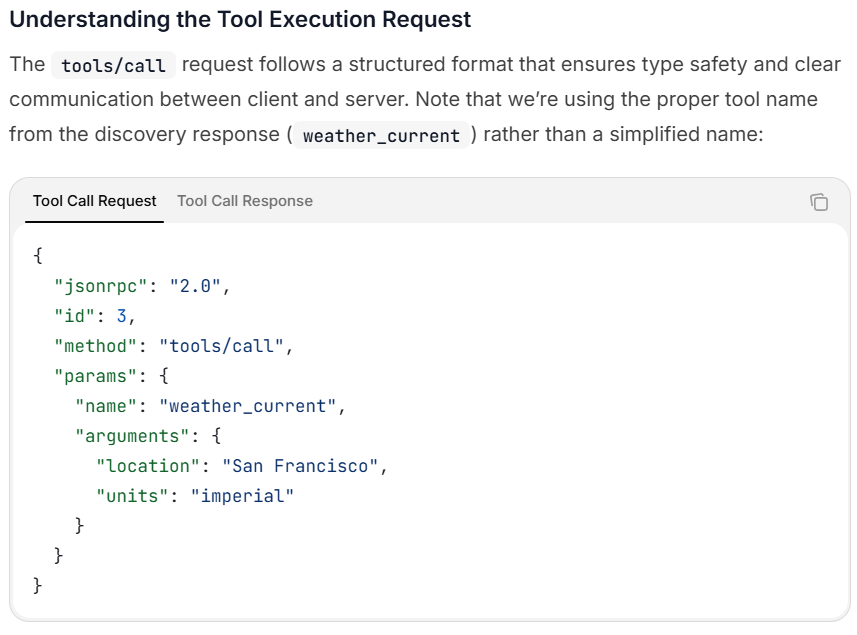

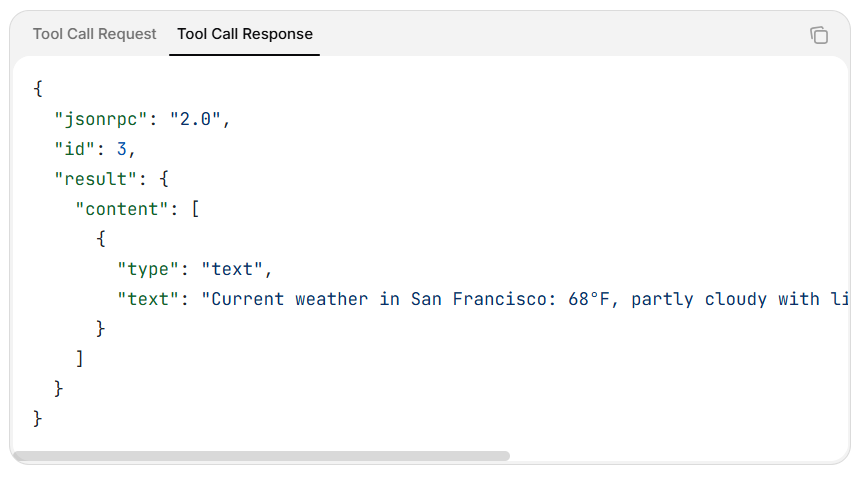

Model Context Protocol (MCP) is a structured method for AI applications and agents to securely discover data, call tools, and share context. Developed by the engineering team at Anthropic in 2024, it has now received widespread adoption across major technology providers, such as Microsoft and OpenAI.

In simple terms, it enables large language models (LLMs) to communicate reliably with other data sources.

Q4. What MCP adoption is happening today?

It is still early, but MCP adoption is accelerating rapidly. Most software companies are developing MCP servers. Many B2C applications already exist, and there are now a growing number of industrial applications, such as those from Highbyte, Flow Software, and Siemens.

Q5. What will “MCP-compliant” mean for AI developers?

From a developer’s perspective, this should be easier than crafting individual application programming interfaces (APIs) that require strict mapping between software products. Any changes on the other end of the system would normally require the API to be restructured. MCP is expected to support inheriting updates without code changes and provide a more uniform setup.

Q6. How would MCP specifically benefit heat treat?

In the last 30 years, I have seen three waves of technology. The first wave was automation that leveraged PLCs, setpoint programmers, and carbon probes to reduce manual errors and improve utilization.

The second wave focused on regulations in aerospace (AMS2750) and automotive (CQI-9) to harmonize auditing processes, improve quality, and reduce in-use failures (reducing recalls). These regulations focused on ensuring ongoing equipment capability (such as TUS for furnaces and ovens), instrumentation and quality thermocouples via SATs, independent calibration, and operator procedures and training.

The last wave focused on Industry 4.0 and IIoT to further automate and optimize previous improvements. However, apart from some isolated cases, many Industry 4.0 solutions have not delivered the expected value. There are many potential reasons, but one standout is the focus on continued machine automation at the expense of human intervention.

The benefit of MCP is that it acts as a bridge between data and the people who need to use that data to improve processes.

Q7. What are the biggest adoption barriers (and how to reduce them)?

I am typically an early adopter of technology. I was asked to automate a manual sealed quench furnace (batch integral quench) to automatic setpoint and carbon control in the early 1990s, which was one of my first projects. I began exploring technology solutions for Industry 4.0 and IIoT back in 2013. There will always be both early adopters and laggards.

Sometimes it makes sense to wait until technology matures and becomes more reliable, but this feels different. For the first time, data will build upon data, and learning early from that data will put companies ahead.

Cybersecurity and IT policies will scrutinize any new technology. One opportunity for AI is to also strengthen cybersecurity robustness. I recently heard that if you do not respond to a technology breach within 30 minutes, you will lose significant data. Human intervention alone will not be fast enough. AI is truly a double-edged sword.

There is also a growing fear that AI will take jobs. This has been demonstrated in the software industry, where it is estimated that 30 percent of code is now written by AI. I do not believe a heat treater can reduce staff further, since most are already operating with skeleton crews. The real opportunity is to enable all individuals to accomplish more, supported by AI.

The final point is when to adopt this technology. The pace of improvement over the past two years has been tremendous, and we are only now reaching the point where new models are robust enough for industrial application.

Q8. Pace of change: start now or wait?

The base LLMs needed time to improve and become more reliable while reducing hallucinations. Each version of ChatGPT has made significant leaps in knowledge and robustness. The latest model, GPT-5, is beginning to provide the level of reliability needed for industrial applications; this progress will continue.

Q9. What AI-powered products or services will emerge with MCP?

We can do a bit of future gazing. I compiled several ideas as part of my preparation for my presentation at ASM Heat Treat in October. In each example below, you will notice that a human remains in the loop. Instead of manually fetching specific data and information, the agent provides timely information.

EnergyOptimizerAgent — Subscribes to “Power/Furnace*/kW” tags and day-ahead tariff feeds. Models alternate start times and sends a proposal called “propose_shift” to a PlanningAgent. If planners accept, the new schedule is written back to the UNS so control logic and enterprise resource planning (ERP) software stay aligned.

ComplianceAgent — Monitors SAT and TUS counters published by the Edge Process Management (EPM) platform. When drift approaches a set threshold, it issues “propose_sat” with a suggested window and part list. After the test, AuditPackAgent gathers .uhh files and publishes a cryptographic hash so auditors can verify authenticity without manual file transfers.

UniformityMonitorAgent — Streams zone temperatures and compares each batch with stored “golden” fingerprints. If deviation grows, it assembles options, such as rerouting the load or adding a soak. Operators approve or reject through a dashboard.

MaintenanceSchedulerAgent — Reads valve-cycle counts, fan-vibration spectra, and motor current signatures. Calls a computerized maintenance management system (CMMS) tool to open a work order, reserve a slot, and order spare parts when limits are reached.

OperatorCopilotAgent — Listens to every proposal on the MCP bus and presents it in chat form. For example: “Shift Load B932 to 13:30 to avoid the peak tariff. Accept or ask why.” One tap reveals historian trends, specification clauses, and the agent’s reasoning trail, giving junior staff instant context while keeping humans in charge.

Q10. Any drawbacks or cautions with MCP?

AI and MCP will continue to be targets for cybercrime. It is important to architect any solution so that the base control and operation of equipment remain safe, even if the AI layer is breached.

At ASM Heat Treat, I will touch on some architectural solutions that can support safer AI implementations. As with anything internet-related, precautions must be taken. With AI, you also introduce the possibility of human-like imposters.

There is risk in everything we do, and everyone needs to continually assess risk versus reward. In many cases, MCP may tip the balance by providing more value than past technology solutions.

The responses in this article represent Peter Sherwin’s personal views and not necessarily those of his organization.

About The Author:

Strategic Marketing

Watlow

Peter Sherwin is passionate about offering best-in-class solutions to the heat treatment industry. He is a chartered engineer and a recognized expert in heat treatment control and data solutions.

For more information: Contact Peter Sherwin at peter.sherwin@watlow.com.