This is the second in a 4-part series by Dr. Steve Offley (“Dr. O”), Product Marketing Manager at PhoenixTM, on the technical challenges of monitoring low-pressure carburizing (LPC) furnaces. The previous article explained the LPC process and explored general monitoring needs and challenges. In this segment, Dr. O talks about the data logger and its monitoring capabilities.

(LPC) furnaces. The previous article explained the LPC process and explored general monitoring needs and challenges. In this segment, Dr. O talks about the data logger and its monitoring capabilities.

The Range of the PhoenixTM Data Logger

A data logger, an electronic device that records data over time or in relation to locatio, can be useful in a variety of configurations and modified to suit the specific demands of the process being monitored. A range of models are on the market. At PhoenixTM they include 6 to 20 channels with a variety of thermocouple options (types K, N, R, S, B) to suit measurement temperature and accuracy demands (AMS2750 & CQI-9). Provided with Bluetooth wireless connection for short-range localized download and reset (direct from within the barrier) the logger memory of 3.8M allows even the longest processes to be measured with the highest resolution to deliver the detail you need. An optional unique 2-way telemetry package offers live real-time logger control and process monitoring with the benefits detailed in a later section.

Live Radio Communication

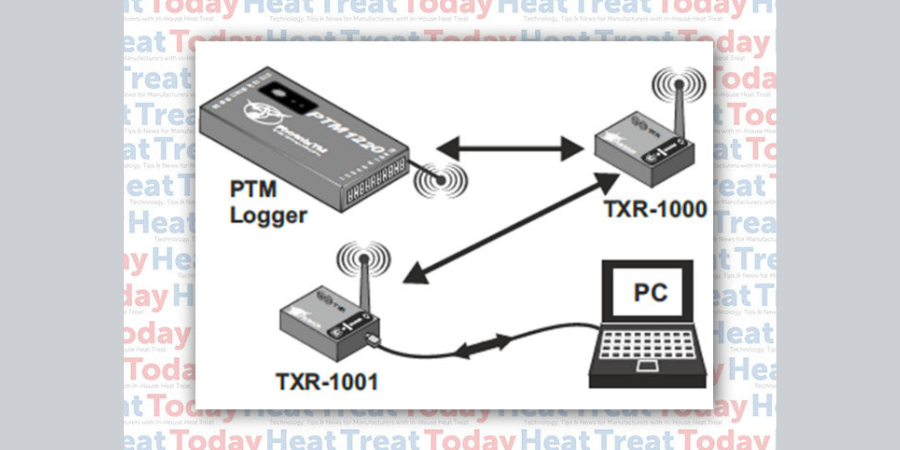

The logger is available with a unique 2-way RF system option allowing live monitoring of temperatures as the system travels through the carburizing processes. Furthermore, if necessary using the RF system it is possible to communicate with the logger, installed in the barrier, to reset/download at any point pre, during and post-run.

Provided with a high performance “Lwmesh” networking protocol the RF signal can be transmitted through a series of routers linked back to the main coordinator connected to the monitoring PC. The routers are located at convenient points in the process, positioned to maximize signal reception. Being wirelessly connected they eliminate the inconvenience of routing communication cables or providing external power as needed on other commercial RF systems.

In many processes, there will be locations where it is physically impossible to transmit a strong RF signal. In carburizing obviously within the oil quench, the RF signal is not capable of escaping when the system is submerged. With conventional systems, this results in process data gaps. For the PhoenixTM system, this is prevented using a unique fully automatic ‘catch up’ feature. Any data that is missed will be sent when the RF signal is re-established post-quench guaranteeing in most applications 100% thru-process data review.

Thru-Process Data Analysis and Temperature Uniformity Surveys (TUS)

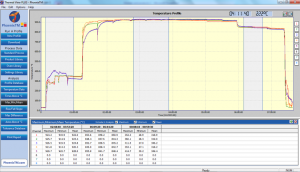

In thru-process temperature monitoring, the data logger collects raw process data directly from the product or furnace as it follows the standard production flow. To understand the data to allow process control and optimization, a Thermal View software analysis is used.

Using a range of analysis tools, the engineer can interpret the raw data. Key analysis calculations can be performed such as:

- Max / Min — Check maximum and minimum product temperature over whole product or product basket through phases of process carburizing, diffusion and quench.

- Time @Temp — Confirm that the soak time above required carburizing temperature is sufficient for correct carbon diffusion and surface properties.

- Temperature Slopes —Measure the quench rate of the product to ensure that the hardening process is performed correctly.

Next up in the series: Designing an Innovative Thermal Barrier — The carburizing process by its nature is very demanding when considering protection of the datalogger from high temperatures and rapid temperature and pressure changes experienced in either the gas or oil quench.