Lead Engineer

DANTE Solutions

![]() “The original LPC schedule, consisting of six boost-diffuse steps, was producing large amounts of carbides during the process. With large amounts of primary carbides in the case of the heat treated gear, rolling contact fatigue performance was decreased.”

“The original LPC schedule, consisting of six boost-diffuse steps, was producing large amounts of carbides during the process. With large amounts of primary carbides in the case of the heat treated gear, rolling contact fatigue performance was decreased.”

Heat Treat Today‘s Technical Tuesday feature, “Low Pressure Carburizing Process Improvement for a Ring Gear: Controlling Carbide Formation during LPC,” explores a case study, written by Justin Sims, lead engineer at DANTE Solutions, about how software modeling aids heat treaters in improving their low pressure carburizing process. Enjoy today’s Original Content.

Introduction

Low pressure carburizing (LPC) processes are becoming more widespread throughout industry due to the reduced cycle times and the control over the carbon profile through the case. Unlike gas carburizing, which utilizes a constant carbon potential to maintain the available carbon on the part surface at a specific value, LPC utilizes a series of boost and diffuse steps. A boost step involves the temporary addition of a carbon carrying gas to the furnace chamber, usually acetylene, to increase the surface carbon to the saturation limit of austenite. If not properly controlled, the carburized case may have an excessive amount of carbon, which damages the final microstructure. After a requisite amount of boost time, generally half minute to several minutes, the carbon carrying gas is evacuated from the chamber. The concentrated carbon in the shallow surface layer from the boost step is then allowed to diffuse into the part, reducing the surface carbon. These two steps are then repeated until the required case depth and carbon profile are achieved.

For steel alloys that do not contain a significant amount of strong carbide forming elements, the LPC process is relatively easy to control. However, with the advent of high strength steels for the aerospace industry, most of which contain substantial amounts of strong carbide forming elements, such as chromium, molybdenum, and vanadium, the LPC process can be challenging. The primary carbides formed during the LPC process, if not properly dissolved, can damage fatigue performance.

While Fick’s Second Law describes the diffusion of carbon through a low alloy steel with reasonable accuracy, the same is not true of medium and high alloy steels. This is due to the presence of carbides forming and dissolving during the LPC process. During a boost step, the carbides formed increase the total amount of carbon into the surface. During the diffuse step, as the carbon that is in solid solution diffuses into the part, reducing the carbon in austenite, the carbides can dissolve to provide more carbon to the solid-state solution. If the carbides are not allowed to fully dissolve or shrink to a significantly small size before the next boost step begins, they will continue to grow. In order to properly predict the carbon profile of medium and high alloy steels, the carbide formation and dissolution must be considered. The heat treatment simulation software DANTE has implemented this feature.

The following is a case study for redesigning a LPC schedule of a ring gear using DANTE. The original LPC schedule, consisting of six boost-diffuse steps, was producing large amounts of carbides during the process. With large amounts of primary carbides in the case of the heat treated gear, rolling contact fatigue performance was decreased.

Geometry and Model

Part: Ring Gear

- Material: Ferrium C64

- Outer Diameter: 5.5 inches

- Inner Diameter: 4.5 inches

- Height: 0.060 inches

- Number of Teeth: 40

Model: Single Tooth

- Cyclic Symmetry: Carbon boundary conditions

act uniformly on all teeth - Number of Elements: 233,850 linear hexagonal

- Number of Nodes: 245,055

- Higher mesh density near surface to capture

steep carbon gradients

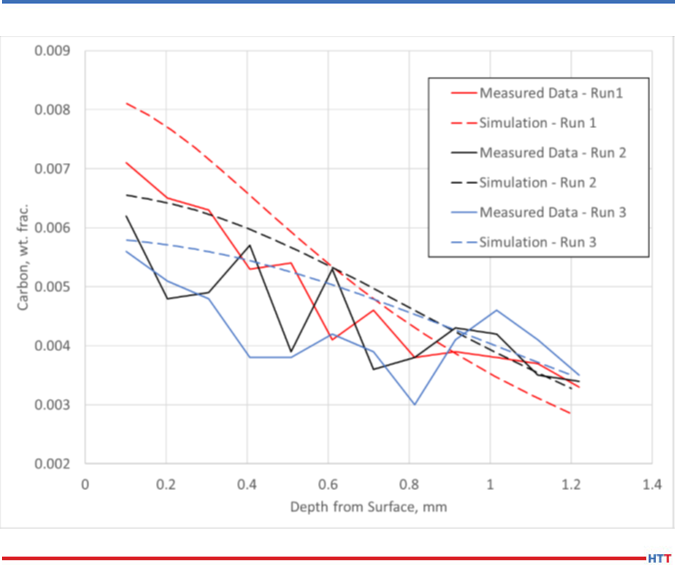

LPC Experiments vs. Prediction

- Experimental data versus DANTE prediction for 3 LPC runs

- LPC experiments conducted using a cylinder with a 4-inch OD and a 4-inch height made of Ferrium C64

- 3 different boost-diffuse schedules executed

- 6 boost-diffuse steps

- All 3 schedules used the same first 11 steps

- Final diffuse time increased for each run, with Run 1 having the shortest and Run 3 having the longest

- LECO used to measure the carbon profile of the test coupons

- DANTE model parameters for carbon diffusivity, carbide formation, and carbide dissolution fit from experimental data

- Simulation matches experimental data reasonably well

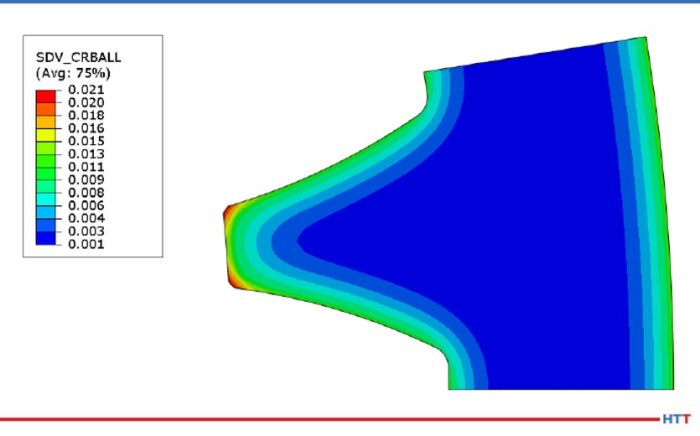

Baseline (Original Carburizing Process) Model Results

- The case depth originally was designed for 0.75 mm (0.030 inch) on the flank of the tooth, with a carbon value of 0.3% resulting in a hardness value of 50 HRC for Ferrium C64 when tempered at 495°C (925°F).

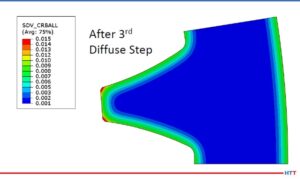

- The contour plot shows all carbon, the carbon in the austenite matrix and the carbon in primary carbide form, at the end of the process for the baseline model:

- Areas above 0.011 carbon contain primary carbides

- Tip contains a high amount of primary carbides

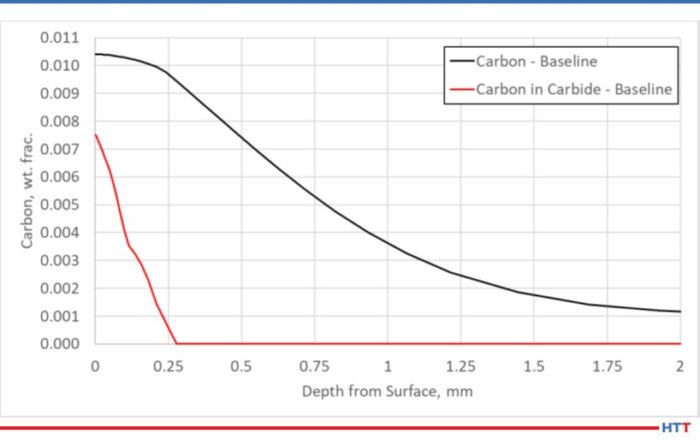

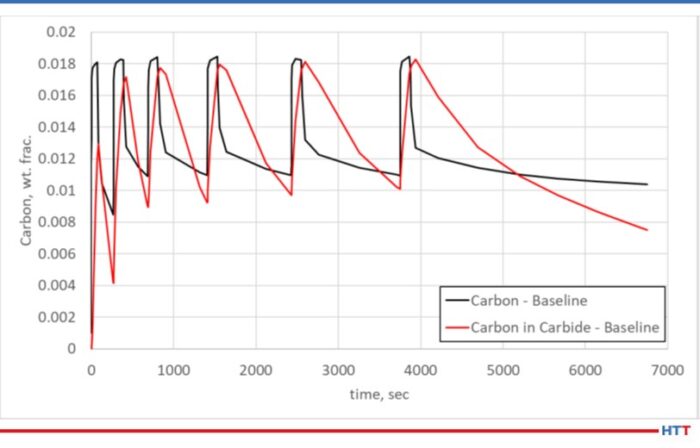

- Line plot shows the predicted carbon in the austenite matrix (Carbon) and the carbon in primary carbide form (Carbon in Carbides) at the surface of the flank for the baseline model over the total time of the process.

- Carbides present at a depth of 0.25 mm (0.010 inch)

- Case depth ~0.35 mm deeper than required

- Contour plot shows all carbon, the carbon in the austenite matrix and the carbon in primary carbide form, at the end of the 3rd boost and diffuse steps

- Line plot shows the predicted carbon in the austenite matrix (Carbon) and the carbon in primary carbide form (Carbon in Carbides) at the surface of the flank for the baseline model over the total time of the process

- Carbides formed during the first boost step continue to grow as the process progresses, indicated by the increasing carbon in carbide

- Final diffuse not long enough to fully dissolve carbides

Redesigned Carburizing Process Model Results

- To ensure the primary carbides dissolve completely before hardening, a new schedule was developed with the aim of reducing the carbon in primary carbide form:

-

- 3 boost-diffuse steps were removed, and the diffuse times increased substantially.

- An increase in diffuse time increased the schedule by approximately one-half hour, which is acceptable given the positive results.

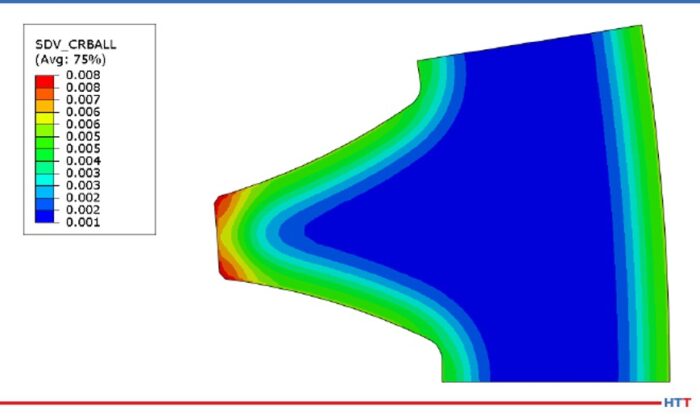

- The contour plot shows all carbon, the carbon in the austenite matrix, and the carbon in primary carbide form at the end of the process for the redesigned process model.

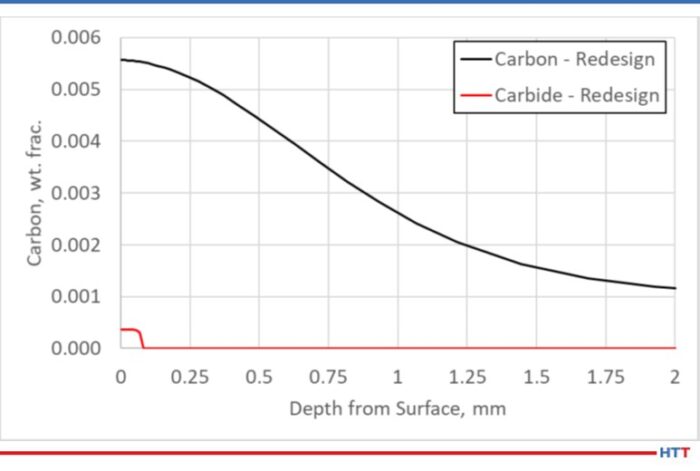

- Line plot shows the carbon in the austenite matrix (Carbon) and the carbon in primary carbide form (Carbon in Carbide) from the surface of the flank towards the core for the redesigned model at the end of the process

- Small carbides (negligible) at a depth of 0.1 mm (0.004 inch)

- Easily removed with finish grinding operation

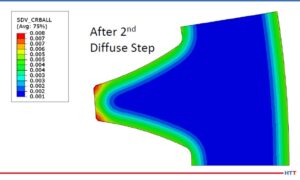

- Contour plot shows all carbon, the carbon in the austenite matrix and the carbon in primary carbide form, at the end of the 2nd boost and diffuse steps for the redesigned process

- Primary carbides are nearly fully dissolved, even in the tip (carbon is higher, but it is not in carbide form), at the end of the diffuse step

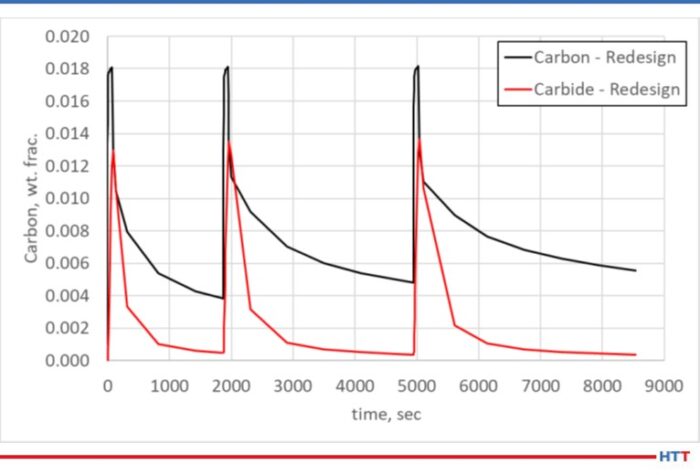

- Line plot shows the predicted carbon in the austenite matrix (Carbon) and the carbon in primary carbide form (Carbon in Carbides) at the surface of the flank for the redesigned model over the total time of the process

- Carbides are nearly fully dissolved after each diffuse step

Summary

- The heat treatment simulation software DANTE model parameters for carbon diffusivity, carbide formation, and carbide dissociation fit from experimental data.

- Any steel alloy and LPC equipment can be fit to the DANTE carburizing model.

- The software successfully predicted the results of a low-pressure carburizing process that was resulting in poor part performance during rolling contact fatigue:

- Model showed that large primary carbides exist at a depth of 0.25 mm (0.010 inch).

- Model showed that the carbides do not have time to dissolve during the boost steps.

- The software was used to successfully redesign the boost-diffuse schedule to improve rolling contact fatigue performance:

- Model showed that small primary carbides (negligible) exist at a depth of 0.1 mm (0.004 inch).

- Model showed that the carbides nearly fully dissolve during the diffuse steps.

- Small carbides were removed during the finish grinding operation.

- Rolling contact fatigue performance improved due to the absence of primary carbides near the surface.

- Additionally, the software is not limited to Ferrium C64 with respect to primary carbide formation during LPC:

- Continually updating the material database with carbide behavior for different alloys

- Continually validating the model with experiments

About the Author: Justin Sims is a lead engineer at DANTE Solutions. For more information, contact Justin at DANTE Solutions

All images were provided by DANTE Solutions.