Knowing the precise temperature from within your continuous heat treat process is now possible. In this Heat Treat Today Technical Tuesday article, Steve Offley, “Dr. O,” Product Marketing Manager at PhoenixTM identifies how this innovative temperature profiling system can help you with your continuous aluminum brazing or other processes.

Knowing the precise temperature from within your continuous heat treat process is now possible. In this Heat Treat Today Technical Tuesday article, Steve Offley, “Dr. O,” Product Marketing Manager at PhoenixTM identifies how this innovative temperature profiling system can help you with your continuous aluminum brazing or other processes.

This article appeared in the edition June 2020 edition of Heat Treat Today’s Automotive Heat Treating magazine.

In the automotive industry, aluminium brazing is key to many of the manufacturing processes used to produce radiators, condensers, evaporators, etc. The quality of the brazing process is important to the performance and product life for its intended function. A critical requirement of the brazing process is the optimization and control of the product temperatures during the complete brazing process. A valuable tool to achieve such requirements is the use of ‘Thru-process’ temperature profiling as a direct alternative to the traditional trailing thermocouples as discussed in the following article. Obtaining the product temperature profile through the brazing furnace gives you a picture of the product/process DNA.

The Basic Brazing Principle and its Temperature Dependence

Aluminium brazing employs the principle of joining aluminium metal parts by means of a thinly clad soldering ‘filler’ alloy, whose melting point is lower than the base/parent metal.

As part of the brazing process, control of the product temperature is critical to achieve selective melting of the filler alloy 1076°F-1148°F (580°C -620°C) to allow it to flow and fill the joints between the parent metal substrate without risk of melting the substrate itself. Often the difference between the melting points of the two materials is small, so accurate temperature monitoring through the entire furnace is critical to the success of the brazing process.

[spacer color="3366ff" icon="fa-lightbulb-o"]

PhoenixTM works with major automotive radiator manufacturer customizing a brazing barrier solution to meet their specific application needs.

PhoenixTM works with major automotive radiator manufacturer customizing a brazing barrier solution to meet their specific application needs.

PhoenixTM was approached by a major automotive radiator manufacturer in the USA. The manufacturer had a specific need for a reliable CAB brazing monitoring system that would withstand heavy use, approximately 45 runs per week. The two companies collaborated to design a unique barrier solution which was adopted for standard profiling use.

“The new barrier is great; the operators love them. All those design iterations paid off.”

It is estimated that barriers supplied back in 2014, which have seen routine use over five years and are still operational, have accumulated in excess of 2,500 successful profile runs without damage or any wear problems. Over the same period, many conventionally designed barriers have been scrapped due to HF acid damage of cloth and microporous insulation. The customer for this reason has now standardized the TS08 design for all their CAB profiling activity.

[spacer color="3366FF" icon="Select a Icon"]

Critical Challenges of the Brazing Process

Prior to any brazing process, it is important that the substrate surface is prepared correctly to allow the brazing process to work correctly. Surface preparation before brazing may involve thermal degreasing where the substrate temperature is elevated to drive off lubricants. A second more important procedure is the removal of any surface oxide layer to allow wetting, and therefore flow of the brazing filler alloy over the parent substrate. Unfortunately, aluminium is easily oxidized and the resulting aluminium oxide (Al2O3) prevents such wetting processes. Therefore, prior to brazing, the oxide layer needs to be eliminated. In most cases, cleaning of the substrate layer is achieved by the application of a corrosive flux, which in a molten state, dissolves the oxide layer.

The type of flux used must be matched to the application substrate and filler alloy composition. A common brazing process used today is that of the Nocolok Process® in which the flux is potassium fluoroaluminate K 1-3 AlF4-6, a white powder deposit.

For the reasons discussed above, elimination of oxygen - and especially water - from the brazing process is a critical requirement, so the furnace is generally run under a nitrogen atmosphere (Controlled Atmosphere Brazing ‘CAB’ Oxygen < 100 ppm, Humidity < -40°F /-40°C). The design and construction of monitoring systems needs to be carefully considered, as discussed later, to ensure that the furnace atmosphere is not contaminated (by oxygen and water), in any way.

Design Principles and Challenges of a "thru-process" Brazing Furnace Monitoring System

The ‘thru-process’ profiling system concept is based on the principle of sending a data logger through the brazing furnace which is protected from the heat and harsh brazing environment by a thermal barrier. Multiple thermocouples connected to the product test piece (radiator), which are connected directly to the data logger, measure the product temperature (and furnace) as it travels through the furnace storing the information in the data logger memory. The resulting temperature profile can be reviewed, analyzed, and a validation report generated. As the system is compact and travels with the product, there is no need to use the cumbersome and potentially hazardous challenge of feeding (and retrieving) long thermocouples through the furnace, as required in the use of traditional trailing thermocouples.

Innovative Thermal Barrier Design

The thermal barrier has the job of providing thermal protection to the data logger. Although this is the case for aluminium brazing, the barrier also needs to be designed in such a way as to avoid damage to itself from potentially hostile corrosive chemicals generated in the furnace, and prevent contamination of the CAB atmosphere from barrier outgassing materials.

Traditionally, thermal barriers are manufactured employing micro-porous block insulation wrapped in high-temperature glass cloth. During use, moisture trapped in the insulation block is released within the barrier cavity where it can form hydrofluoric (HF) acid in combination with chemicals in the brazing flux. Over only a short period of time, the highly corrosive HF acid can cause significant damage to both the barrier cloth and insulation. This compromises the integrity of the barrier, reduces its thermal performance, and potentially creates a dust contamination risk to the process.

Air trapped in the micro-porous insulation block and within the barrier cavity during heating can expand and escape from the barrier into the furnace. Obviously, being made up of 21% Oxygen (O2 (g)), the air will contaminate the CAB environment, and potentially create a risk of aluminium oxide formation resulting in wetting/brazing problems.

To eliminate the damage to barriers, extend operational life expectancy, and minimize outgassing of air (O2(g)) or moisture, PhoenixTM developed a unique new TS08 specifically for the demands of CAB brazing.

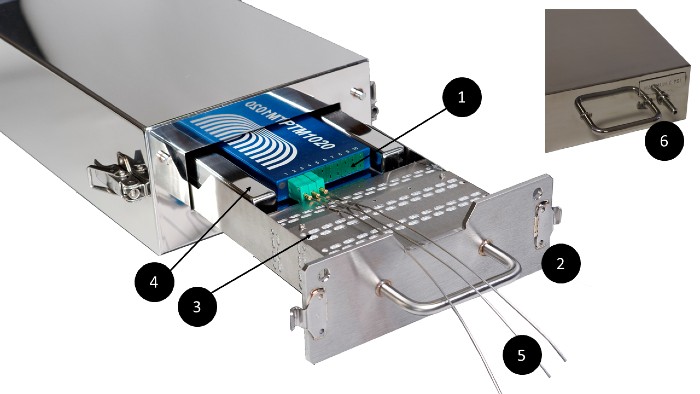

As shown in figure 1, the logger draw loading mechanism significantly reduces the amount of insulation cloth that is exposed to the aggressive flux. Prior to supply, the insulation block is preheated in a high vacuum and back flushed with nitrogen (N2(g)) to drive out any air trapped in the porous insulation structure. For processes where any air outgassing is a significant contamination risk, it is possible, with specific barrier configurations, for customers to purge the small barrier cavity of any remaining air with a supply of low-pressure Nitrogen (N2(g)).

- PhoenixTM Datalogger with 6, 10 or 20 Channels

- Front loading logger tray with encapsulated thermal insulation protecting from HF

- Thermal breaks reduce heat conduction to logger

- Heat sinks provide additional thermal protection employing phase change technology

- Mineral Insulated Thermocouple inserted into radiator fins

- Rear barrier optional Nitrogen feed nozzle for pre-run purging of insulation and barrier cavity of air (02(g))

Unveiling the Mystery of your Brazing Furnace with a ‘thru-process’ Temperature Profile Trace

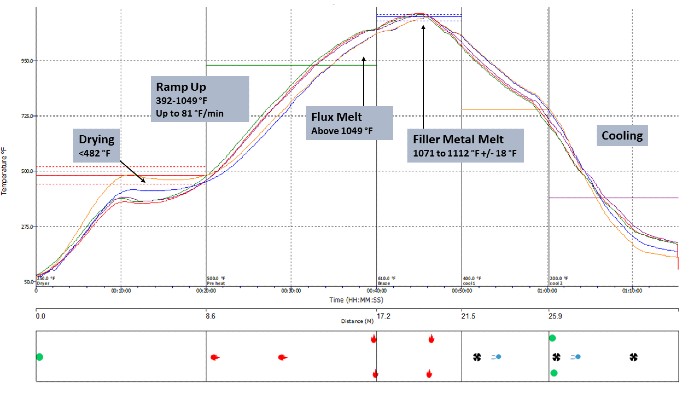

The key temperature transitions/phase of the brazing process are clearly shown on a typical temperature profile as in figure 2.

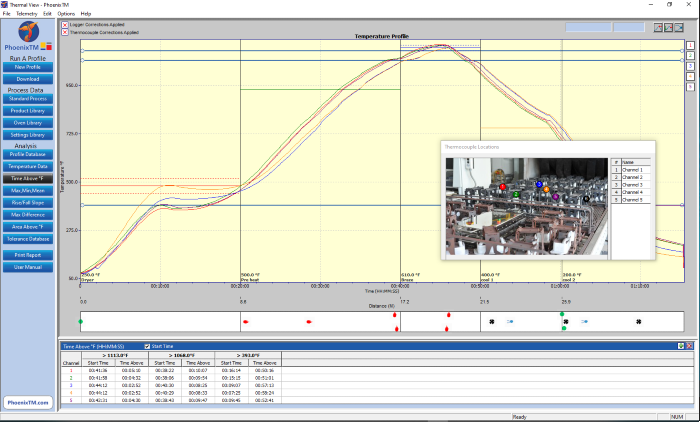

The brazing system is supplied with Thermal View Plus software, which is designed to provide full analysis and reporting tools for monitoring the brazing process against the monitoring requirements detailed in Table 1.

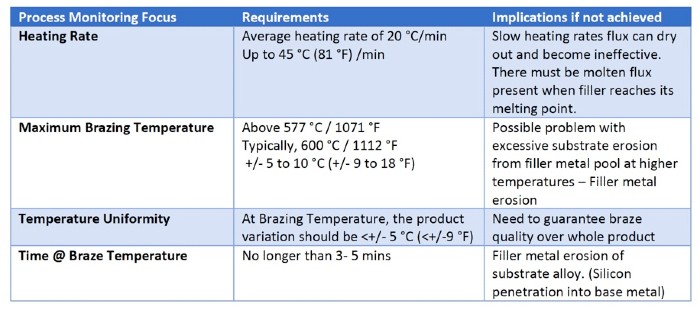

Below in Table 1 is a summary of the target temperature transitions in the CAB brazing process, the impact on process, and possibly, the quality of the brazed final product.

The PhoenixTM brazing system is supplied with Thermal View Plus software, which is designed to provide full analysis and reporting tools for monitoring the brazing process against the monitoring requirements detailed in Table 1.

Overview

The PhoenixTM ‘Thru-process’ brazing system provides a rugged, reliable, and clean solution for performing product temperature profiling of Automotive CAB brazing furnaces. Providing the means to Understand, Control, Optimize and Certify the brazing heat treat process.

About the author: Steve Offley, “Dr. O,” the product marketing manager at Phoenix TM, is an experienced global marketing manager with a demonstrated history of working in the industrial temperature monitoring industry over the last 25 years.

For more information, contact Steve at Steve.Offley@phoenixtm.com.