Today’s episode revolves around gun parts: How are they heat treated? How many gun component manufacturers are there in the U.S.? Doug Glenn, publisher of Heat Treat Today and host of this podcast, and Steve Kowalski, president at Kowalski Heat Treating, dive into this topic and what it takes to heat treat gun parts.

Below, you can watch the video, listen to the podcast by clicking on the audio play button, or read an edited transcript.

The following transcript has been edited for your reading enjoyment.

Doug Glenn (DG): Well, welcome to another episode of Heat Treat Radio. I have the immense pleasure of being able to sit down today with Steve Kowalski of Kowalski Heat Treating. Steve, you know, it’s nice to finally sit down with you. We’ve been talking for quite some time about doing this, so first off, welcome to Heat Treat Radio.

Steve Kowalski (SK): Well, good morning, Glenn. Thank you very much for having me today.

DG: You are very, very welcome. Now, we have to start, as I told you before hit the record button, over your left shoulder there is an interesting ball. You need to tell us about that real quick.

SK: Can you see it?

DG: Yes, yes, we can see it.

SK: For you and folks at home, this is a rubber band ball. For perspective, how’s that? It’s twenty-two plus years in the making.

DG: For those of you who are on the audio only version, it’s about the size of a basketball. Steve was telling us that you guys [Kowalski Heat Treating] have been using only the stuff that comes in the U.S. mail. It’s very impressive. It has nothing, absolutely nothing, to do with heat treating, but I did want to say that it’s pretty interesting.

Anyhow, Steve, we’re going to talk a little bit today about the heat treatment of guns, ammo, and that type of stuff. That’s just to whet the appetite of those who are listening and watching; that’s what we’re going to be talking about a bit, your organization does it.

But I’d like to have you take a minute just to talk about your background, very briefly. I know that it’s a long, long background . . . . ~chuckle~

SK: Careful, careful!

DG: Yes, I know! Trust me, you and I graduated from college the same year, so I know. So, it has been a long background. But briefly, tell the listeners/viewers about you, about the company, and then we’ll jump in with some questions about firearms.

SK: Wonderful. I’m second generation. My dad started the business back in 1975, so I was underage working, yes. Those of us in the commercial heat treat, a lot of us have grown up in businesses where we were the underaged employees. The transition took place about 15 years ago. We started off with one building, roughly 3,000 square feet, to process tools and dyes. Back in the day, Cleveland was one of the tool and dye capitals of the world- we had tons of tool and dye makers. Well, that business has evolved away.

Since 1975, we’ve grown the business to now having nine facilities on our campus, roughly 80,000 square feet, and those of you who know Kowalski Heat Treat, we specialize in those PIA jobs — it’s what we do. If it’s a problem, it’s pretty sure that it’s going to be coming to our facility.

We started in salt bath. Over the years we added high pressure quench vacuum processing, plasma nitriding, plasma nitrocarburizing, heat pyrogenics. One of our divisions specializes in nothing but keeping parts flat- round and flat. You can go to our website at KHTE.com and check out the various divisions and what we do. Basically, in our world today, we rack or assemble 95-97% of everything that comes through this door — it’s specially handled.

DG: The PIA, the “pain in the ass” ones is what you’re talking about. Do you guys have, therefore metallurgists and things of that sort on staff, as well, I assume?

SK: We have 48 people, we have 8 engineers on staff — anything from chemical to mechanical to electrical. We do not have any metallurgists on staff. We have access to great metallurgists in the area.

DG: Cleveland has them.

SK: Oh, my gosh, we actually are blessed here in Cleveland. If you need something — one phone call and we can find it.

You’re from Pittsburgh, aren’t you?

DG: Yes, just north of Pittsburgh. Don’t hold that against me.

SK: No, no, it’s okay — you’ve done remarkably well. ~chuckle~

DG: All things considered, there you go. I appreciate that. How very gracious of you, Steve!

SK: Oh, my pleasure.

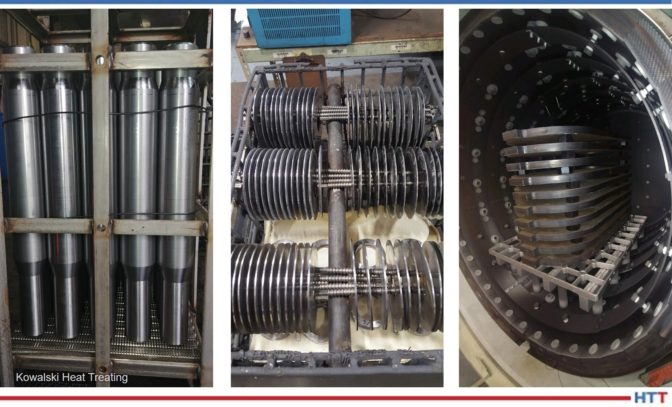

Source: Kowalski Heat Treating

DG: You’re right, though. Cleveland, I think, especially. Ohio, in general, but Cleveland, in general, are kind of like the forging center of the world. There’s just a lot that goes on there. But heat treat, in between Detroit and Cleveland, it’s kind of “heat treat central.”

Well, listen, that’s great. You’ve obviously been very successful. You’re good at what you do. I know it’s still a family business --- you’ve got you and your sister, at least, involved, right?

SK: Sisters, yes, correct. Two sisters are involved: one in the back office and Peggy Andrews is inside sales customer service. You’ve met Peggy.

DG: We’ve met Peggy; we know Peggy. Peggy is wonderful.

SK: And for all of you listening — I’m the quiet one in comparison.

DG: I believe that, now. I’ve met Peggy and she’s great.

Also, you’ve been a little bit humble because you were the president of the Heat Treat Society not too long ago, were you not?

SK: Yes.

DG: Which is quite an honor.

SK: Before me was Roger Jones and after me was Jim Oakes.

DG: Let’s talk firearms for a second. You know, it’s kind of interesting, because when you talk firearms, it’s always a little bit controversial. Obviously, there’s a political side to this conversation. We don’t really want to go down that road too much because we’re just going to talk about heat treatment. But I do want to ask you, which could be slightly bumping up against the political side: Have you seen, recently or in the recent past, any increase in that business that Kowalski is doing as far as firearms go?

"Well, in our firearms business (and I know we’ll be talking about the who, what, where, when, why of firearms and how processing is incredibly important), we work with the DOD (Department of Defense) and very unique programs, we work across the spectrum in the firearms from long guns to handguns and there seems to be a huge misconception in the world on firearms. ATF controls that world from the registration standpoint."

SK: Well, in our firearms business (and I know we’ll be talking about the who, what, where, when, why of firearms and how processing is incredibly important), we work with the DOD (Department of Defense) and very unique programs, we work across the spectrum in the firearms from long guns to handguns and there seems to be a huge misconception in the world on firearms. ATF controls that world from the registration standpoint. Every firearm has a serial number (certain components of it) so it is tracked. Our systems have evolved over the years — we’ve developed specific systems that are very sophisticated to be able to track the product that we process. The key components that require serialization or a serial number — we track them. We do hundreds of thousands of units a year, and they’re all tracked so that you and I can go across the political side. We’re really very, very proud of the fine work that my team does in the firearms industry. Most of our first responders, law enforcement, defense — they require and depend on what we do. I can make it very dramatic, but in reality, if we don’t do our jobs correctly, they can’t do their jobs correctly.

DG: Yes. And it’s somewhat of a life and death thing, too. I mean, if you’ve got malfunction because of a defective heat treat, or for any reason, it can be an issue.

SK: Our business has definitely grown in the last seven years. We’ve built a very good reputation in this industry. If you have a problem, chances are we’re going to be working with you to help you solve your problem. Firearms are extremely highly engineered with very tight tolerances.

DG: It’s kind of interesting, here, because you’re talking about serialization of parts and things of that sort that come in; you’re not getting fully assembled guns — you’re getting parts and pieces. So, you’re able to track— I’m curious, is that tracking a barcode, is it optical — how do you do it?

SK: The answer is “yes” to all of the above. It depends on the customer. If you have a sales agent, you have a serial number or you have a code and, in some cases, some of our customers are moving toward QR codes. So, if you receive in 10,000 units, whatever they may be, well that’s 0 to 10,000 and you need to ship 0 to 10,000 back. If you do not, ATF is notified.

DG: That’s interesting. Types of furnaces: Are you guys running batch furnaces or are you running continuous furnaces?

SK: We do batch. The majority of what we process for the gun world, for the firearms world, would be either salt to salt rack austempering or marquenching, vacuum and actually plasma processing, whether it’s FNC or nitriding. Those three areas, we’re involved with the gun world.

DG: Yes, I was curious, because you hear a lot about, especially. It’s a different market, but in the faster world, you hear fallout. If you’re going through a mesh belt furnace, you know, “Oh well, you lost a few fasteners down on the bottom of the furnace.” That would not work in your . . . .

SK: I can make light and we joke a little bit about it, but you do not want folks with three letters on the back of their coat coming in.

DG: Exactly. If that happened, probably the next interview we’d do with you, you’d be wearing an orange suit and maybe you’d have a roommate.

SK: And I just don’t look good in orange.

DG: So, now, as far as the firearms industry, there are a lot of different metals and materials of that sort, but there are two basic things — I mean, I always talk about it and we talked about this a little bit before we hit the record button: There is ammunition and then there are gun components. You guys do not do ammo, correct?

SK: Correct. That is not a world we’re in. We are in the gun side — all of the components for guns. On any given firearm, you may have, in our particular case, we may be processing 12–15 different components for a handgun — anything from a barrel to a slide to a receiver to a firing pin, ejectors, extractors, triggers, trigger guard — the list goes on. It tends to be a different material; there are different properties that they develop that they need a firing pin versus a trigger guard versus a slot.

DG: Just a quick example if you don’t mind. It’s important for the heat treater to know what they’re doing, obviously, right? Why is that? Can you give us an example of why it is?

On any given firearm, you may have, in our particular case, we may be processing 12–15 different components for a handgun — anything from a barrel to a slide to a receiver to a firing pin, ejectors, extractors, triggers, trigger guard — the list goes on. It tends to be a different material; there are different properties that they develop that they need a firing pin versus a trigger guard versus a slot.

SK: Well, when you say “a barrel” is true. If a barrel is not “true,” straight, no distortion. We’ve all seen various TV shows where the person swings the gun around and the bullet shoots around the corner. No. Doesn’t happen. So, if the barrel isn’t true and hasn’t been processed appropriately and correctly, it’s not going to function the way it was designed.

A firing pin, which is a very distortion-sensitive component- if it’s bent, it doesn’t work. The gun will not fire. We could go on: slides and receivers. If they’re distorted, they’re not going to work. It’s not going to function. So, each component must be processed to achieve dimensional tolerance control. And then metallurgically, the structure: A gun has a very aggressive action.

DG: Mini explosions, basically.

SK: Literally. And so, it’s been designed to support all of that.

DG: The different components that I think about are the firing pin you were mentioning, right? It’s going to have a lot of impact on the shell casing on the firing pin.

SK: In that particular case (and we’re not giving any IP away), but those are austempered for structure. Doug, are you a metallurgist?

DG: No, I am not, actually.

SK: Nor am I. I’m a marketing guy, folks, with experience.

DG: Same here, same here.

SK: The design — if that pin chips, cracks, breaks, it doesn’t fire.

DG: Exactly. So, you’ve got the high impact parts like the firing pin, you’ve got barrels where you want good wear resistance and things of that sort and, obviously, they need to be true and straight. You’ve got springs in a lot of guns, especially your Ruger style where the receiver’s back — those things have to be heat treated appropriately.

Steve, what type of alloys typically are we talking about in some of these different parts?

SK: They range from high carbon materials (1050, 1060, 1070) up to high temp stainlesses, whether it’s 400 series, whether it’s a precipitation hardened series, mid to high alloy materials (4340, 4150) and then, as we get into the specials, the engineering world is continually trying to make a better product- a longer acting product, a more robust product- so we’re starting to see materials that, historically, weren’t used in this area. Plus, things that we don’t deal with, there are many components that are carburized using 8620, 9310, carburized and hardened, for the same purpose: wear and performance.

DG: Being in the Cleveland area, you are kind of in another hub and that’s where a lot of this 3D printing, additive manufacturing; I mean, there’s a lot that goes on there. I think there’s an organization in Youngstown, or in that area, that’s kind of a central hub there. Are you guys seeing any of that, whether it be in firearms or not? Have you had any experience with any of the AM?

SK: The answer is yes. AM is absolutely taking place; it’s incredible. The technology — what you can do today that you couldn’t do two or three years ago and then you have to effectively engineer backward forward, make it, and then make it right, then produce it, thermally process it (maybe); so, it’s one of those.

DG: It’s an interesting and evolving technology.

As a heat treater of gun components, not that you want to help any competitors or anything of that sort….

SK: Heck no, we love all of our competitors who are not working against us, how’s that?

DG: That’s fair enough, that’s fair enough.

As a heat treater, what are the things that jump into your mind that you have to be careful about when heat treating gun components? And if it helps, pick a specific component, whether it be a pin, a barrel or whatever. What do we need to be careful of?

SK: I’m looking up over your head (which is beautiful, by the way) at the sky here in Cleveland, Ohio. The way I’m going to answer this is this: You are dealing with a component that, if we take guns out of it and, say, use medical devices. We’ll use medical devices in lieu of saying guns so people can appreciate where I’m going with this. You have bad players out there — people who are trying to circumvent the system. With medical devices, you need to have approvals — you need to have FDA. It’s very similar in the gun world- you need approvals, you need make sure that they’re making components that comply with, whether it’s the OEMs’ specification or ATF specification being sterilization (making sure things are marked appropriately). Internally, here, we have secure quarantined areas where we do all of this work. Your personnel — I have to be approved to be able to process these parts. My background has to be checked.

This company, my company, approves those people who can touch these components. Internally, we have secure, bonded areas. Parts are bonded in and they are bonded out. Use the terminology you like, but basically, you’re securing from our floor to an area because it is that important. If we’re dealing with the aerospace world or nuclear world, you are going to make sure your systems and processes and procedures are all locked down.

DG: So that’s a procedural, operational uniqueness, let’s say, to handing guns. How about technically? Like in the aerospace industry, you’ve got NADCAP, in automotive you’ve got, you know, in aerospace still you’ve got AMS for pyrometry, CQI-9 and things of that sort. The medical industry, which you mentioned, Steve, has MedAccred and things of that sort. Any such beast in the firearms? I haven’t heard that there is.

SK: Basically, we have overlapped between our guns and gun industry as a whole with the DOD work that we do, so we go back and forth. What you mentioned here, most of those requirements and procedures are already in place. It makes it easier if you’re doing CQI-9 relevant work, you’re not going to start and stop. So, the equipment is already covered in those areas. The procedures — you build them so that you’re not building fourteen different procedural systems. It’s difficult to control.

DG: You’ve already kind of answered this but let me just ask it straightforward just in case there’s something else, and if there’s nothing else, that’s fine. For the people in your company and for you guys, generally speaking, is there any specific training or knowledge or experience that you have to have to be heat treating gun components?

SK: Yes. And those are: one, experience is an incredible teacher and often times. For Kowalski Heat Treat (I can’t speak for competitors, I’ll speak for us), normally, if a product hits our floor, hits our dock, hits my inbox, historically, somebody has had a problem with processing that component — whether it’s distortion, whether it’s metallurgically the properties they’re achieving, whether it’s actually out in the field — you’re my favorite, you’re my test. You’re going to call and say, “Hey, Steve, I got this thing and I’m not happy with its performance and I need to improve its performance. What can we do?” Then you start the entire investigatory process of what have you done, what have you achieved, did you actually test or are you just feeling that what you’re telling me is you’d like to have something better but you don’t know what? So, we have a design team here that will work very closely with your folks to help design a better process, a more robust process. If we’re talking to the general industry, as we are right now, I think we can all agree that the quality and consistency of the materials that we are receiving in today are dramatically different than they were five years ago, eight years ago, ten years ago.

SK: Worse. Worse being not as consistent as they were. Yes, we all have that grade A and four of us will process grade A today and we will get result B. Next week you’re going to get B-, B+, possibly an A, maybe a C.

We’re joking internally, but the first thing most heat treaters do — because, quite frankly, we’re paranoid; the entire world is out to get us and it’s always the heat treaters fault. . . . It’s always our fault. So, the first thing we do when enter into a relationship is we say, “Doug, hi, I’m Steve. I’m sorry.”

DG: Get that out of the way, start out that way.

SK: Then we move forward from there. But that has been a serious challenge on the consistency of the materials coming to us.

DG: So, you guys test all incoming material?

SK: Yes. And don’t use the word “all.” But yes, we have an inspection and we work closely with customers. As you get your material in, send it to us. Before you start making a product, send us something that we will process and validate for you so that you know that what you’ve got will respond the way you thought it’s supposed to respond. Then, we can move forward being more efficient with that.

DG: You’ve hit on this before, too, but I just wanted to see if there are any other comments that you want to make on this and that is the type of equipment that is necessary for doing the heat treating of these gun components. I know you mentioned salt, so you’re in a salt bath, right?

SK: Salt neutral hardening, salt hardening, and then marquenching or austempering, depending on the component. It’s critical. There are a significant number of parts that respond extremely well to rack austemper, rack marquenching. Extremely well. And we’d probably say that our team here, they’re spectacular. I get to talk about it which is really pretty cool. Hey, I’ve got these great people with me that do this great work, and they do! Their job is to make me look good. As you know, your support staff, yes, don’t even say it, I know it’s a fulltime job, it’s never done . . . . ~chuckle~

DG: You took the words out of my mouth! ~chuckle~

SK: So, salt is critical in this industry. Vacuum processing.

DG: Why did you go vacuum, by the way?

SK: With stainlesses and the various materials that we’re currently using, having high pressure quench vacuums/high pressure quench, it allows for a significant amount of flexibility. We can finetune a recipe, or cycle, to achieve properties that the customer needs where it makes it repeatable.

DG: And you’ve got, what, how high pressure? What bar are we? Ten bar quench?

SK: Yes.

DG: So, you’ve got salt to salt, you’ve got high pressure gas quenching coming off of a vacuum heat treat. Anything else?

SK: And then we do plasma nitriding. I will say that we have the technology we have utilized to optimize processing. Is ours the best for everything? Absolutely not. No question about it. And when it’s not, we’re going to say, “Hey, Billy, I need you to call Doug and I need you to tell Doug that Steve said to call him and ask the following three questions. Doug’s got the answer for you.” And your equipment for his application is better than mine; it works best. So, I think anyone in the heat treat world can recall the scars on our backs from the days that we thought we could give you exactly what you need [indiscernable]. It’s not the best answer.

DG: Do you do much heat treating of gun components in straight atmosphere or air furnaces?

SK: We don’t have them.

DG: You don’t have them at all. And do you do induction?

SK: No, not yet. No oil quenching here whatsoever. We’re here in Cleveland in a residential area and we are zero quantity generator of hazardous waste.

DG: Nice. I’m sure your neighbors appreciate that.

SK: Oh, they absolutely do.

DG: If they know.

SK: Oh, they do.

We know what we’re really good at and that’s our work.

DG: A couple more questions on this. We talked about the uniqueness of heat treating gun components because of the traceability and the serialization and all that stuff. Is there anything else technically unique about the heat treatment of any of these gun parts that kind of make them interesting or more of a challenge?

SK: Yes. Have you met my wife?

DG: I don’t believe that I have.

SK: There is a comment that she tells me all the time: Everything that goes through my mind doesn’t have to come out my mouth. She’s incredibly wise and way smarter than I am!

In the heat treating world of gun components, one of the areas that would be critical is it is not a bulk processing world. It’s not about running more and more and more parts at one time. You will not get optimum results. It’s a sensitive process. We’re heat treaters and we’re very sensitive with what we do.

But distortion is critical. The way the parts have been designed, you cannot effectively, in my humble opinion, put them into a 2436 or 3648 basket and max load it — you will not get optimal results. It’s not going to happen. So, there is a tremendous amount of racking.

"In the heat treating world of gun components, one of the areas that would be critical is it is not a bulk processing world. It’s not about running more and more and more parts at one time. You will not get optimum results. It’s a sensitive process. We’re heat treaters and we’re very sensitive with what we do." - Steve Kowalski, Kowalski Heat Treating

DG: That, actually, was my question: Not that you would know this number right off the top of your head or anything, but the percentage of time spend racking, I assume, is higher.

SK: It’s 2:1, 3:1, 4:1, 5:1.

And, for those of your listeners who understand salt processing, we can rack for two days and process for an hour/two hours.

DG: Let’s say it’s just manually intensive, then.

SK: We have an incredible team of individuals here who do things that, if you watch, you’re just like…. In some cases, it’s truly awe-inspiring because they create for us success. They help us learn new ways of processing. It’s not, hey, you’re going to do it the way Steve says. Critical process control, but they provide us the answers on making things better.

DG: I’ve got two other quickie questions for you. We may have already covered them. One was just if there is any common mistakes? I know you guys don’t make mistakes, but . . . .

SK: Heat treaters do not make mistakes!

DG: That’s correct. But is there any common mistakes with the heat treatment of gun components? Because, if you guys really are, as you say, the people that are taking care of the PIA jobs, it’s usually coming from people who have made a mistake.

SK: Yes. It’s when to say no. You and I have talked and we’ve talked to our peers — they’re brilliant people. We tend to all lament, usually, the same thing. Something comes in and it’s not quite right or correct and we don’t say, “Stop. Doug, you did not make this correctly. We can’t do what you want us to do because of you’ve provided to us.” Or the next step would be folks who assume.

But the rest of it is process control. Once you develop, you rock the process and when you do that, the only real big issue we’ve run into anymore is consistency of material coming in.

DG: I’ve heard, and I want to be careful, and we may have to edit this out, but you mentioned incoming material specs being an issue, the consistency of the material coming in. I have heard that a lot of times the inconsistency in that material is coming in from overseas, let’s just put it that way, and not necessarily Europe.

SK: Far overseas.

DG: Far overseas. Let’s just say far to the East overseas. I guess my question is: Is that still the source of it or are you seeing less issues with that?

SK: Because of what we’ve run and because of the customers that we’ve worked with, historically, that hasn’t been a big problem — not in this market. Although there is high volume, it’s not a tremendous amount of weight. It’s more of the chemistries, the supply chain. We’re hearing it. Part of it is frustrating stop saying supply chain when your guy just didn’t show up and do his job. But, as heat treaters, we will say, we have to be very diligent in contract review. There is mentoring of our younger employees, customers mentoring their younger employees who don’t have the knowledgebase, yet, to understand what they’re actually working with. It’s not a disparaging comment — you learn from making mistakes. You absolutely learn, and that’s experience. So, we’ve seen a talent drain in the last few years. And that is exacerbating the problem.

DG: Right now, you’re doing heat treatment of gun components. Obviously, I’m not going to ask you company names because that wouldn’t be the right thing to do, although it would be fun to do, but it wouldn’t be the right thing to do. But are you pulling in business, let’s say, from pretty much nationwide?

SK: Yes. We don’t get a significant business from overseas. This is due to transportation challenges. Plus, it’s part of our continuous supply chain worth being manufactured, let’s just say, in England, and then ship it to the states to do X, Y and Z, and it ends up being assembled in some state in this country. But as far as countrywide, continent-wide: yes, we’re all over the country.

DG: Do you think the normal guy, like myself (I’m going to classify myself as a normal guy, in this case), would be surprised at the number of gun component manufacturers in this country?

SK: Yes.

DG: Because when I think of gun manufacturers, I’m thinking there are maybe a half dozen to a dozen at most.

SK: Try a different number.

DG: Try a different number — maybe add or multiply that. See, I don’t know!

SK: We’ve been very fortunate that we’ve attended and been at the SHOT show; it’s been held in Las Vegas for the last number of years. You get a better perspective attending that. Now, you have to be approved to attend it, and those who have understand where I’m going with this. There are a number of manufacturers in this country. And we’re not talking about folks who . . . . I’m a family business — we are a family business; we have 45–48 people. We are a small business. I’m talking about companies with hundreds of employees that you’ve never heard of that make components and guns and support that industry.

It’s a significant industry and, by and large, without getting into the politics of this, some of the nicest people we have ever met — truly just generous. I’m talking about even purchasing agents! (For those of you who have dealt with purchasing agents in industries that we will not discuss that have four wheels and an engine!) They’re basically decent people. It’s fascinating.

DG: It kind of rocks your world when a purchasing agent is a real person. It’s like, Oh really, they have heart.

Well, listen Steve, congratulations. It sounds like you guys are doing great work there. I know that you guys do more than guns. Do you care to share, just briefly, what else you do?

Source: Kowalski Heat Treating

SK: Those that know the company, when we say PIA stuff: if it’s a problem, it’s coming to us. Distortion sensitive. We have a significant market in power transmission, clutch plates, brake discs, big round flat things, visually, from three inch in diameter to 50 inches in diameter — that’s our world. You name the market: power transmission, auto . . . . We don’t do much in the aerospace industry; it’s just not something that my people and I want to deal with. Other than that area, medical, nuclear, Department of Defense. We do a significant amount of research and development where folks like you say, “Hey! I have an idea! Can you help us?” and we assist them on the metallurgical heat treat side on building processes. Outdoor power equipment. Basically, if you have a problem, I’ve got 10 guys for you who are incredible at what they do. We just like having problems. I’m telling you how we work: If I can solve your problem, if our team can solve your problem, are you going anywhere else?

DG: Exactly right. Nope, not going to do it.

SK: And we like to try and have fun doing it.

DG: Yes, that’s right. Get the work done and enjoy it if you can.

Steve, listen, I really appreciate you being here, I appreciate you talking to us a little bit about guns and ammo, I guess mostly gun parts. And, again, congratulations, it sounds like you guys are doing well. We appreciate your insights.

SK: It’s a pleasure, an absolute pleasure. Thanks, Doug.

For more information, contact:

Website: www.khtheat.com

Doug Glenn

Publisher

Heat Treat Today

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio .