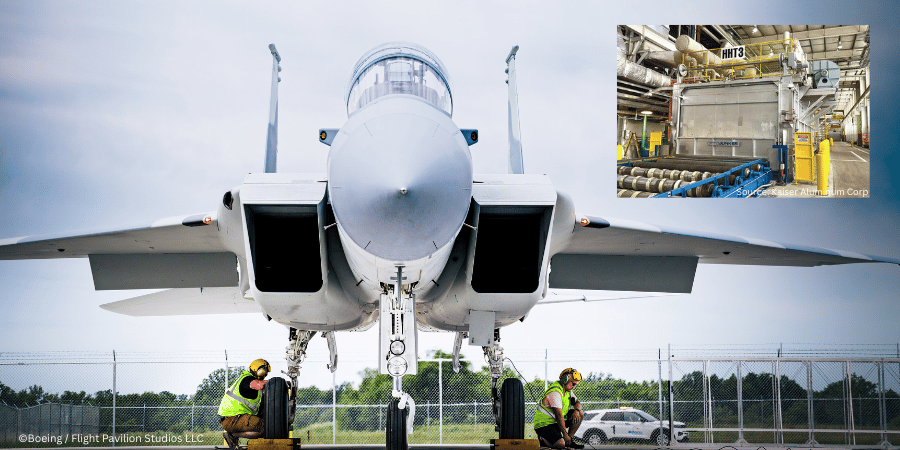

Kaiser Aluminum Corp., a producer of heat treated, flat-rolled aluminum products, has completed a $25 million expansion of its Trentwood rolling mill in Spokane Valley. This marks the latest phase of the company’s long-term strategy to increase heat treatment throughput for aerospace, automotive, and general engineering markets.

The original source was published in Spokane Journal of Business, and the following content has been adapted for our Heat Treat Today audience.

The project, which is part of more than $415 million invested in the facility over the past 20 years, extends one of the mill’s major heat treat furnaces, increasing plate-processing output by approximately 5 percent. For in-house heat treaters, the upgrade reflects a continued industrywide push toward higher-capacity, efficiency-driven thermal operations as demand for tight chemistry and reliable mechanical properties climbs.

Source: Kaiser Aluminum Corp.

According to Kevin Barron, vice president of manufacturing, the expansion enhances the mill’s ability to heat treat and stretch large-format aluminum plate products without altering staffing levels at the 1,000-employee site. The project was completed within the plant’s existing footprint with support from regional contractors and furnace supplier Otto Junker USA.

The Trentwood mill, one of only three U.S. sites capable of producing heat treated aerospace-grade plate, has undergone seven phases of reinvestment since 2005. Recent work builds on earlier additions to the facility’s furnace lineup, along with upgrades to hot rolling, homogenizing, and casting capacity — areas closely linked to the performance and consistency of downstream heat treating.

Kaiser paused expansion activities during the pandemic, storing some equipment purchased pre-COVID. With the current project complete, the company has reestablished its pattern of continuous, phased improvements intended to keep pace with global aerospace and defense demand.

For manufacturers with in-house heat treat operations, Kaiser’s latest phase underscores a broader trend: large producers are expanding thermal processing capability not only to increase volume but to ensure uniformity, cleanliness, and repeatability at scale. As aerospace OEMs tighten specifications, upstream suppliers are reinforcing their heat treatment infrastructure to meet rising expectations for precision and throughput.

Kaiser Aluminum, headquartered in Franklin, Tennessee, operates 13 facilities across the U.S. and Canada. The Trentwood site remains a key supplier to Boeing and other aerospace manufacturers, continuing a relationship that dates back to World War II.

Press release is available in its original form here.