Dogs come in all shapes, sizes, and colors, and in the case of certain breeds, they are also prone to higher incidences of hereditary defects, deformities, or infirmities.

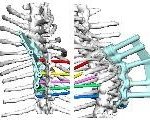

Small dogs can present particular health issues that are a challenge to correct because their size and weight offer little to no margin for error. In dachshunds and Shih Tzus, abnormal bone growth can sometimes cause their front paws to point outwards. And pugs, and other breeds with corkscrew tails, are susceptible to spinal problems caused by misshapen bones. Fortunately, if diagnosed in time, these conditions can be treated with surgery, but with such small animals, corrective surgery to drill and cut bones, stabilize vertebrae or reposition limbs is a laborious and intricate process.

Two animal specialists from Britain, Dr. Kevin Parsons, an orthopaedic vet based at the small animal hospital at Langford Vets, in Bristol, and a former colleague Tom Shaw a neurosurgeon, now at Willows Veterinary Centre and Referral Service in Solihull are pushing the boundaries of additive manufacturing in veterinary science and are applying it to both scenarios. They have been exploring the world of 3D-printed anatomical guides and titanium implants, manufactured on a GE Additive Arcam EBM Q10plus in South Wales, as a means to provide animals suffering from malformation an opportunity to live longer, pain-free lives.

Integral to Langford Vets’ additive journey has been its partnership with Swansea-based CBM Wales (CBM) – a commercially focused advanced research, product development and batch manufacturing facility, established by the University of Wales Trinity Saint David.

Dr. Ffion O’Malley and an experienced team of additive manufacturing designers and engineers at Swansea-based CBM Wales (CBM) — a commercially focused advanced research, product development and batch manufacturing facility, established by the University of Wales Trinity Saint David — oversee production of bespoke surgical guides (either in polymer or metal) and titanium implants to match exactly to each individual patient’s anatomy to restore mechanical and/or aesthetical functions. Each implant design, follows precise specifications from the Langford Vets’ surgical team, using CT or MRI diagnostic imaging data.

The Q10plus is particularly well-suited for medical implant manufacture and has been developed for easy powder handling and fast turnaround times. The EBM process takes place in a vacuum and at elevated temperatures, which results in stress-relieved implants with properties better than cast and comparable to wrought materials.

The bespoke implants are built in Titanium Ti6Al4V ELI, which is certified to the USP Class VI standard for biocompatibility and is extensively used for FDA and CE marked implants. CBM has ISO 9001:2015 certification for the provision of a design, prototyping and small batch manufacturing service and ISO 13485:2016 & EN ISO 13485:2016 certification for the design and manufacture of custom made 3D-printed surgical guides and implants.

Click here for additional images and more information.

Photo credit: Langford Vets, CBM Wales