In heat treating, the choice of power supply is a critical decision. Whether you’re using an AC transformer or a rectified DC system (AC transformer rectifier), this decision plays a significant role in process efficiency, equipment longevity, and operational costs. While AC transformers have been the industry standard for decades, rectified DC power is becoming more relevant due to its distinct electrical and thermal characteristics. Understanding the differences between these two power sources helps in-house heat treaters optimize furnace performance based on their specific application needs.

This informative piece was first released in Heat Treat Today’s May 2025 Sustainable Heat Treat Technologies print edition.

Electrical Differences: AC vs. Rectified DC Power

AC Transformer Systems

In a traditional setup, an AC transformer steps down high-voltage grid power to the appropriate level for the heating elements. These elements operate on an alternating current waveform, where voltage and current fluctuate between positive and negative cycles at a standard frequency (typically 50 or 60 Hz).

Rectified DC Systems

In a rectified DC system setup, an AC transformer is combined with a rectifier to convert the stepped-down AC voltage into a pulsating or smoothed DC supply. This provides a continuous electrical current rather than an alternating waveform, changing how heat is delivered to the furnace.

Heat Distribution and Process Stability

One of the key differences between AC and rectified DC power in furnace heating is how each affects heat distribution within heating elements.

AC Heating

The alternating nature of AC power means the voltage crosses zero multiple times per second, leading to cyclic fluctuations in power delivery. In heat treating, this can create small but notable variations in temperature stability, especially in high-precision applications where uniform heating is critical.

Rectified DC Heating

Because DC power provides a continuous voltage and current, it eliminates these fluctuations. This results in more stable and consistent heating, which can be beneficial in processes that require tight thermal tolerances, such as carburizing, nitriding, and annealing.

Heating Element Performance and Longevity

The type of power supply can also impact the lifespan and efficiency of heating

elements.

AC-Powered Heating Elements

Alternating current can cause thermal cycling effects within the heating elements, leading to mechanical stress over time. This may contribute to faster wear, increased oxidation, and potential premature failure of heating elements in some applications. However, for many general heat treating processes, AC remains a cost-effective and widely accepted solution.

Rectified DC-Powered Heating Elements

The stable power flow of rectified DC reduces thermal cycling stress on heating elements, allowing for longer operating life and more efficient heat transfer. This is particularly relevant for graphite and silicon carbide heating elements, which perform better with steady-state power input.

Power System Efficiency and Infrastructure Considerations

When integrating AC vs. rectified DC systems into a heat treating operation, several infrastructure and efficiency factors come into play.

- AC Transformer Systems:

- Standard in industrial settings and require minimal modification to existing electrical infrastructure

- Simpler and often lower cost installation compared to rectified DC systems

- More efficient for long-distance power transmission, which can be a factor in large industrial operations with multiple furnaces

- Rectified DC Systems:

- Require a rectifier in addition to the transformer, adding to equipment costs and complexity

- Potentially higher efficiency in localized heating applications by reducing resistive losses in certain furnace designs

- Reduced electromagnetic interference (EMI) compared to AC, which can be beneficial in sensitive heat treating processes

Process Suitability: When to Use AC vs. Rectified DC Power

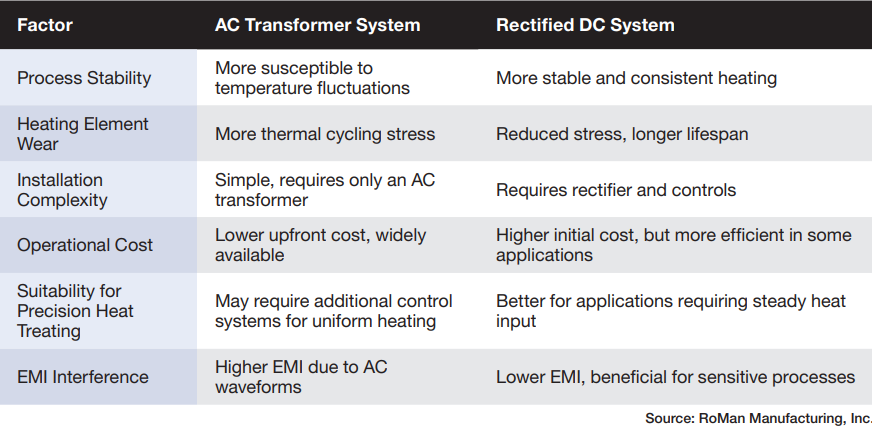

Temperature stability, heating uniformity, and process sensitivity are important factors to consider when choosing between AC and rectified DC power for different heat treatment processes.

Conclusion

Both AC and rectified DC power play important roles in heat treating, and the choice depends on process requirements, equipment lifespan, and infrastructure considerations. AC transformer-powered systems remain the standard due to their low cost, compatibility with existing grids, and simpler installation. They are ideal for general heat treating applications that do not require extreme precision in thermal control. However, rectified DC systems offer more stable heating, reducing wear on heating elements and improving temperature uniformity. While they require additional equipment, they can be beneficial in high-precision applications or when maximizing furnace efficiency is a priority.

Understanding the strengths and limitations of both AC and rectified DC power sources enables heat treaters to

select the optimal system for their specific production needs, balancing cost, efficiency, and process performance.

About The Author:

Sales Applications Engineer

RoMan Manufacturing, Inc.

For more information: Contact Brian Turner at bturner@romanmfg.com.