In this Technical Tuesday installment of Combustion Corner, Jim Roberts, president of U.S. Ignition, examines various burner nozzle shapes, sizes, and effects. Use this helpful resource to evaluate whether your own in-house heat treat burners are the right choice for your applications.

This informative piece was first released in Heat Treat Today’s September 2025 Annual People of Heat Treat print edition.

A furnace guy walks into a bar and shouts “Straighten UP!” The other furnace guys turn to furnace guy #1: “It won’t work!” Just like last month. Let’s continue this topic.

What would you say if I asked you, “What does fire look like?” How would you describe fire to me — color, size, smell, temperature? It’s kind of a weird thing to try and do.

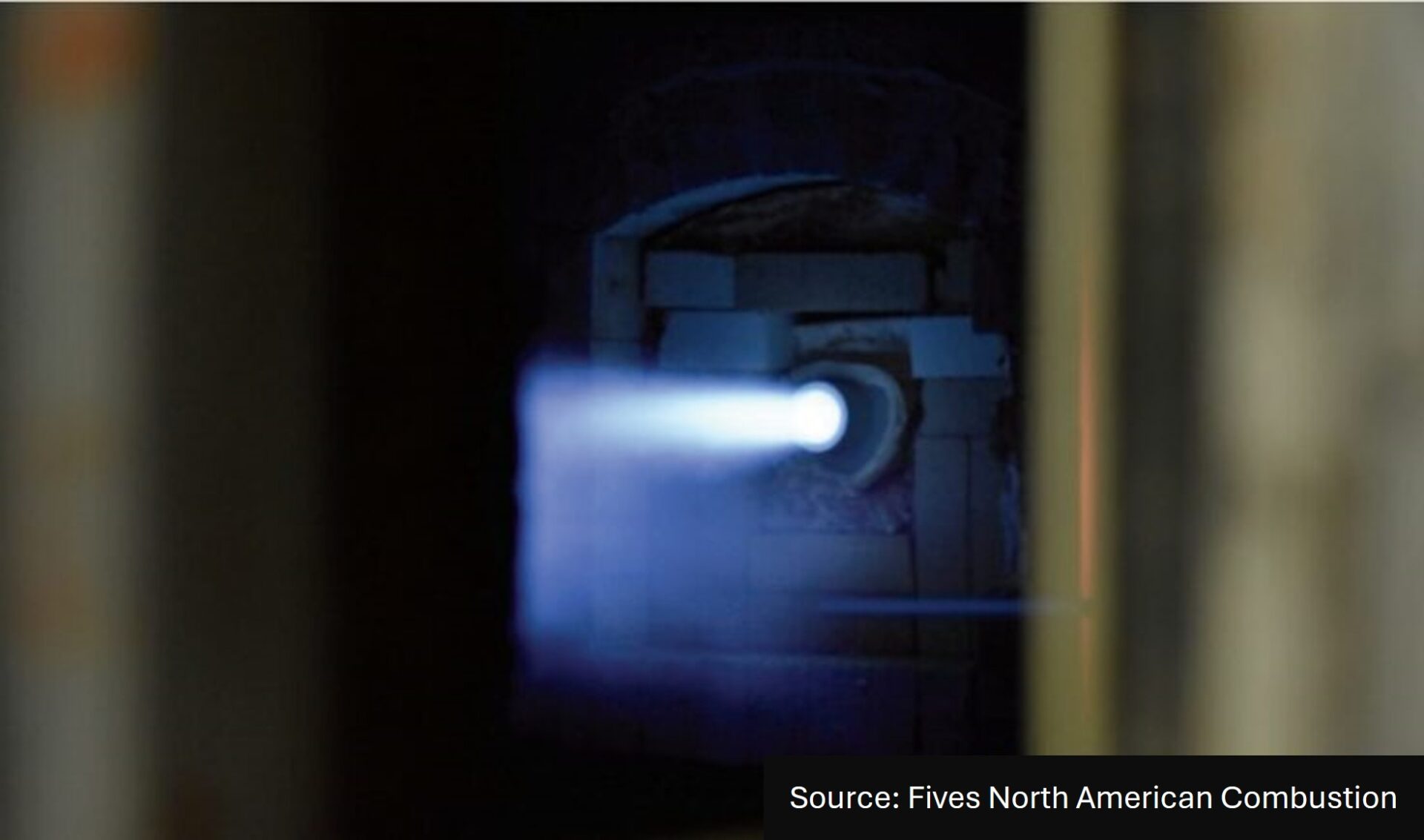

Last month, we ended by talking about how “air staged” burner design can make the flame exit the nozzle at a whopping 270 mph. There’s a reason that trade names for some of these burners are “Therm-Jet” and “Tempest” and “Hot Shot.” In these instances, velocity and turbulence are the game. The flame appearance is almost always a pinpoint tip, not dissimilar to what we have all seen spitting out of the tail of a fighter jet aircraft.

And, as an interesting aside, these high-velocity industrial burners can be victims of the same phenomena as a jet engine: flameouts. A tremendous amount of design time and testing has been dedicated to keeping the flame “retained” on the nozzle. If the flame lifts off the nozzle, cup, etc., it risks being blown out by the high-velocity stream of gases being produced in the guts of the burner. At these speeds, you cannot count on the burner backlighting, so a flame failure is imminent.

More Burner Types

The other types of nozzle-mixing burners are flat flame burners. These are sometimes called wall huggers or radiant wall burners. In these designs the idea is to have as little forward momentum to the flame as possible and to run the burners in a fuel-rich or highly luminous state. The design features are such that the whole wall of the furnace will be glowing radiantly and using radiation from the glowing walls to heat the product.

There are also infrared burners, where the burners are like a porous foam or screen grid and flame just glows on these surfaces. Again, the intent is radiant heat as opposed to velocity gases. These are very prevalent continuous production processes where radiant, consistent heat is required.

There are also radiant tube burners, where the flames are fired through an alloy or ceramic tube, and the flame is isolated from the process completely. The idea here is that the tube does not allow the products of combustion to make contact with the parts. Also, in most radiant tube furnaces, some sort of process atmospheres — comprised of a variety of gases to protect the products in the furnace from oxidation or to impart a metallurgic property to those parts — have been introduced to the chamber and the process.

As such, burner design engineers have to figure out how to give a very uniform heat delivery to the tube they are firing into. Many times, a burner will need to mix the air and gas very slowly (compared to direct fired furnace burners) to ensure the flame releases its radiation at a very uniform rate, so as to not distort the radiant tube itself. And the users of these variety of burners range from flame hardening to direct fired to indirect fired atmosphere processes and many more.

We will continue this discussion point in subsequent columns because understanding these burners is critical to using them correctly. As for the original idea that flame shapes can affect all sorts of process performance, we will revisit this topic and others, because it’s all important. Different flame shapes can significantly impact combustion performance by influencing factors like flame speed, stability, heat release, and certainly one of the big design goals now, emissions reductions. We’ll tackle these topics in future columns.

Until then, I would suggest that you take a walk into the plant and check out the variety of burners that you may have. Let’s endeavor to find more about them and consider, “What would make this burner the right choice for this application?” Then, discover what you can learn about them and their history. We will tie that all together when we discuss the next installment.

President

US Ignition

Contact Jim Roberts at jim@usignition.com