This week’s Technical Tuesday installment is a Heat Treat Today original from our upcoming Automotive magazine, which is scheduled to be released in June.

This week’s Technical Tuesday installment is a Heat Treat Today original from our upcoming Automotive magazine, which is scheduled to be released in June.

Deciding on a process cooling system for your automotive heat treat needs is an important process that needs intentional consideration. Check out this practical and valuable guidance from Bob Smith, director of product management at Thermal Care to help you make an informed decision.

When considering which type of process fluid cooling system is best for your automotive heat treat application, it is important to determine the process fluid medium, desired temperature, and the significance of operating cost versus initial investment. There are often multiple solutions to a process cooling application, and the following is intended to provide a basic outline of the types of systems available and where they are best used.

Process cooling is moving heat from where it is not wanted (the process), and putting it into the air outside the manufacturing facility. Heat transfer usually involves the use of some sort of heat transfer media, usually a fluid like water or a glycol solution, to transport the heat from the process equipment to the cooling system.

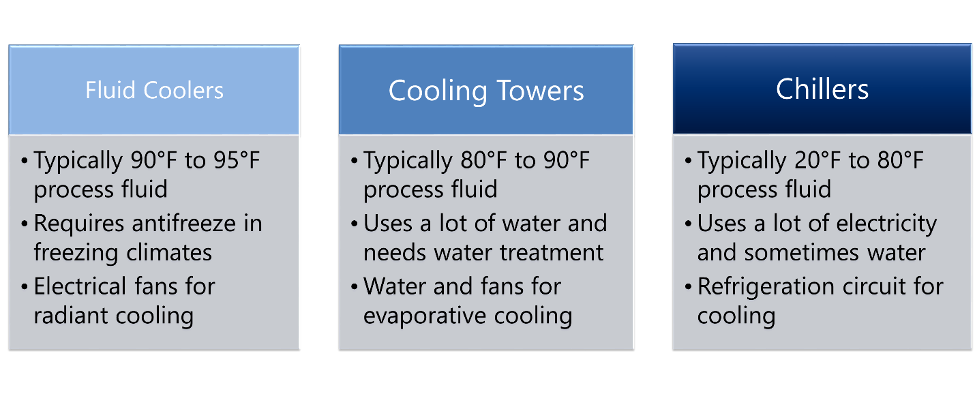

The first step is to understand the required temperature for the process cooling fluid in order to properly remove heat from the process. This is typically specified by the process machine manufacturer and is based on the flow of fluid and the required temperatures of their heat exchangers. There are three basic types of process cooling systems to consider.

Fluid cooler systems are commonly used for applications with warmer temperatures. They consist of copper tubes with aluminum fins and fans that act like a radiator to cool the process fluid using ambient air. The coolest practical leaving fluid temperature is about 10°F warmer than the air entering the fluid cooler. Compared to cooling towers, fluid coolers are not as energy efficient, have a higher initial cost, and have a larger footprint; however, they have much lower maintenance requirements and use less water than cooling towers. Of the three types of process cooling systems, the operating cost and capital investment of fluid cooler systems typically fall somewhere between that of a cooling tower and chiller system.

Cooling Towers

Cooling tower systems are used for applications where a fluid cooler is not able to get cold enough. A cooling tower system can provide a reliable source of cool water year-round in the 70°F to 100°F temperature range. Cooling towers work through the process of evaporation. Water is sprayed over plastic cooling tower fill, which creates a large surface for water to evaporate from. A fan moves air through the tower to induce evaporation, which in turn cools the water. The coolest practical leaving water temperature in summer is about 80°F due to air temperature and humidity. Cooling tower systems are typically the least expensive of the three types of systems to operate; however, the maintenance requirements for filtration and water treatment are the highest of the three.

Chillers

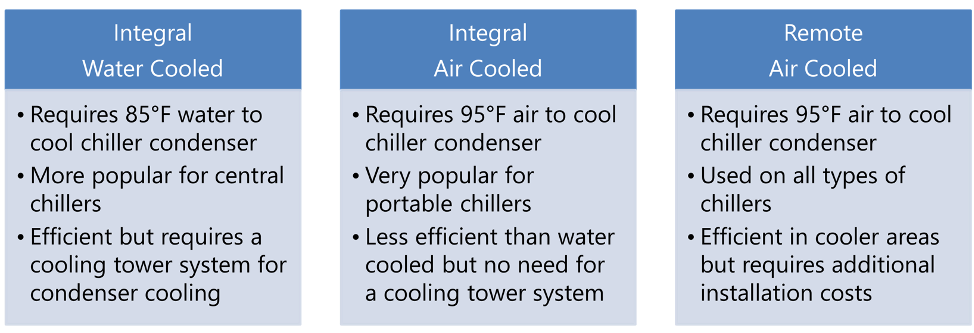

Chiller systems are used in applications where neither a fluid cooler, nor cooling tower system, can get cool enough to meet the requirements for the process. In a chiller, refrigerant is used to pull heat from the process fluid and transfer it to ambient air or cooling tower water. Most applications are for 50°F water, but most chillers have a practical process fluid set point range of 20°F to 80°F. Of the three types of cooling systems, chiller systems are the most expensive to purchase and operate. Chillers require some form of cooling to their condensers, which is where the refrigerant gas that was boiled using the process heat is condensed back to a liquid. The three types of chiller condensers are shown below.

Chillers that use air-cooled condensers have less maintenance and less installation costs than water-cooled condensers, because water-cooled condenser chillers require a fluid cooler or cooling tower system to generate 85°F to 90°F fluid to cool the condenser of the chiller.

With the above basics you will be able to choose which type of cooling system you should consider to cool your process. Once that is known it is best to work with a manufacturer who specializes in that type of process cooling equipment. They will have the expertise and knowledge to help you configure the best system solution and ensure you are able to meet your purchase and operating cost objectives.

Bob Smith, director of Product Management, has over 30 years of experience at Thermal Care having begun as a sales engineer. He has grown with the company over the years serving in a number of different roles such as project manager, inside sales manager, OEM market manager, and director of Plastics Markets.

For more information, contact: www.thermalcare.com or (888)-828-7387