Curious about proper gas atmospheres needed to meet high-tolerance standards for additive manufactured parts before, during, and after the heat treating process?

Learn about them in this detailed original content article from Heat Treat Today’s Aerospace 2021 print magazine. The author, Lisa Mercando, Ph.D., is the marketing manager of strategic marketing & development at Air Products. You can access the other articles in our digital edition here. Enjoy the Technical Tuesday!

Marketing Manager, Strategic Marketing & Development

Air Products

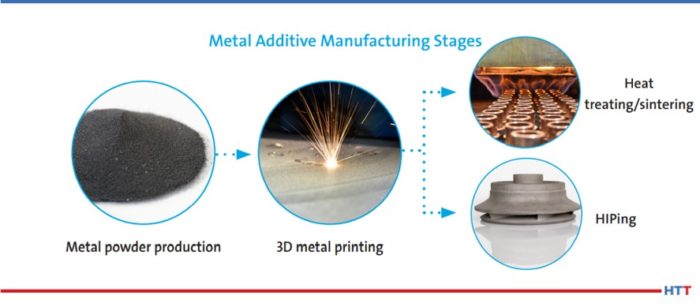

In a world of rapid prototyping and production of metal components, it is imperative to have the proper gas atmosphere to produce quality parts. Argon, nitrogen, and helium are commonly used to create inert atmospheres in order to meet the high-tolerance standards required for additive manufactured (AM) aerospace parts. Industrial gases are used every step of the way from powder production to various additive manufacturing techniques to finishing processes that include heat treating and hot isostatic pressing (HIPing).

Inert gas atomization is the best method to obtain dense, spherical particles, which are best for AM applications where the desired particle size is usually less than 100 microns. Additionally, inert gas atomization greatly reduces risk for oxidation, providing a high level of powder purity and quality. Helium provides the best results when its superior heat transfer capabilities are needed. This process achieves the following properties: dense and spherical particles; high quality and purity metal powders; and narrow particle size distribution. We can provide high pressure gases for powder atomization and hydrogen-based atmospheres for powder reduction and annealing.

To meet the high-tolerance standards required in additive manufacturing–particularly for aerospace–nitrogen and argon are commonly used to provide inert atmospheres. The use of helium, with its high thermal conductivity, offers an interesting option for minimizing the thermal distortion of elongated parts during printing. An inert atmosphere provides numerous benefits on a printed part by:

- reducing oxidation of printed parts by lowering the oxygen concentration in the build chamber

- improving safety through the inerting of combustible dust during powder handling and sieving

- creating a stable printing environment by maintaining constant pressure in the print chamber

- mitigating powder clumping in the feed tube

- preventing part deformation by controlling thermal stress through effective cooling

Gas requirements differ based on the process being used and the material being printed.

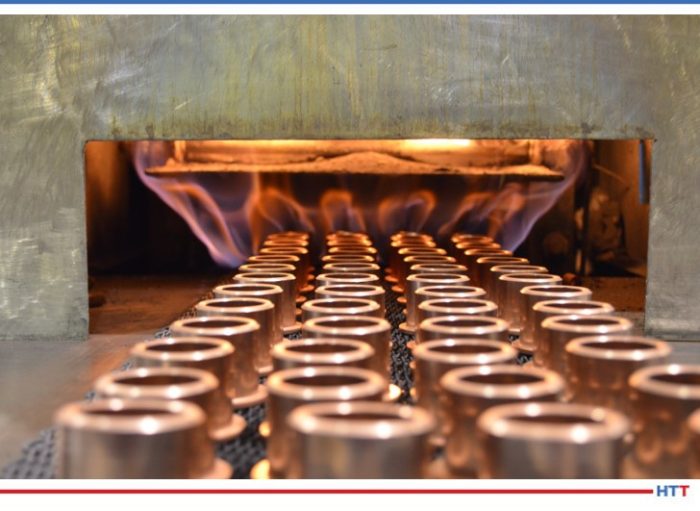

Often, AM aerospace parts require additional processing to achieve the desired final properties. This is done mainly in the form of heat treating, sintering, or HIPing. All three processes have industrial gas requirements for preventing oxidation. Heat treating with argon, nitrogen, hydrogen, or a nitrogen/hydrogen blend can relieve internal stresses and enhance part properties such as strength, ductility, and hardness. In sintering applications, nitrogen/hydrogen blends or argon/hydrogen blends are important in producing near-net shape parts with increased strength and uniformity. High pressure argon is used in HIPing applications to provide fully dense parts with increased strength and reliability.

In addition to providing the bulk industrial gases required, the company has developed state-of-the-art process intelligence systems. These systems monitor atmosphere composition parameters to ensure the process is running with the desired gas atmospheres and provide alerts for any needed maintenance or adjustments. Decades of metals processing experience in gas supply, applications, process knowledge, and safety are applied to help improve heat treating efficiency and part quality.

Remote tank monitoring is one example of the company’s Process Intelligence™. Operators increasingly rely on data to closely track critical process parameters, such as the use and inventory of vital industrial gases. This tank monitoring system enables operators to remotely check their supply levels and monitor usage from a touch screen in the plant, on their laptop, or on their mobile device. Customized daily reports are a common way to stay current on their industrial gas supply.

For heat treatment operations using a furnace atmosphere that is flammable or potentially flammable, an inert purge gas – typically nitrogen – is utilized to help ensure safe operation. This system alerts operators to the condition of the liquid nitrogen supply and helps them remotely track their supply and usage of gases. Optional system alarms allow operators to safely initiate a controlled purge shutdown, enabling compliance with NFPA 86 by confirming they have adequate liquid storage levels, or ensuring their nitrogen piping temperature remains at a safe level. Typically installed near the furnace operation, the remote touch screen on the base station displays conditions of all bulk gas storage tanks and can use both audible and visual alarms to warn the operator of a potentially critical situation.

In addition to using inert gases, such as nitrogen and argon for the 3D printing processes, GE Additive Manufacturing, located in Cincinnati, OH and a major manufacturing center for additive manufacturing, also performs post processing heat treatment/sintering on the metal parts to enhance part quality. Their capabilities allow for the production of quick, precise parts with high levels of accuracy, even on intricate shapes and geometries across multiple applications.

Conclusion

If you are prototyping and producing metal components, be sure to consider the importance of achieving the optimum gas atmosphere to efficiently make quality parts. The heat treat postprocessing of AM metal parts is often required to produce the high-quality parts specified for the aerospace industry.

About the Author: Dr. Lisa Mercando is the marketing manager, Strategic Marketing & Development, for Air Products’ metals processing industry. She has worked at Air Products for 28 years in a variety of roles and responsibilities and is the author of several patents and technical articles.

All images were provided by Air Products.