In this Technical Tuesday installment Christoph Bollgen, industry manager for Thermal Processing Technology, JUMO GmbH & Co. describes how global industries accelerate towards greener, smarter manufacturing. Thermal processing is at a pivotal crossroads of advances in industrial furnace technology, energy efficiency, and sustainable operations set to transform how materials are hardened, strengthened, and perfected.

This feature presents these important developments in thermal processing — from technological developments and energy efficiency measures to digitization, sustainability, regulation, and market growth — supported by current analyses, statistics, and case studies.

This informative piece was first released in Heat Treat Today’s August 2025 Automotive Heat Treating print edition.

Introduction

Thermal processing technology, specifically industrial furnaces and heat treatment processes, are the backbone of numerous industries from steel and ceramics to automotive and electronic components. Over the last five years, this sector has developed rapidly. Driven by new technical possibilities and increasing requirements relating to efficiency and sustainability, significant trends have arisen in industrial furnaces, heat treatment processes, and the market as a whole.

Industrial process heat is essential for many industries, which is why increasing energy costs, regulatory requirements, the shortage of skilled professionals, and international competition pose challenges for companies.

Electrification is increasing in importance, as it offers high process efficiency, emissions reductions, and tried-and-tested technologies. Nevertheless, there are technical and economic obstacles for high temperature processes where limited heat flux densities and high operating costs make complete electrification more difficult.

Hydrogen is being investigated as a possible option for decarbonization in industries that currently use natural gas. However, for the switch to take place, changes to process conditions and material properties are required, while the availability and cost of hydrogen remain decisive factors.

Future decarbonization strategies must be developed for specific industries, as not all processes can be electrified. Both hydrogen and electrical energy require significant changes to the infrastructure to ensure supply security in the long term. The choice between electrification and hydrogen depends on underlying technological, economic, and infrastructure conditions.

Advances in Industrial Furnaces and Heat Treatment Processes

State-of-the-art industrial furnaces and heat treatment systems have made huge advances in a short period of time. Key examples are the new, altered material and product requirements in the automotive industry; more lightweight components and electromobility place higher demands on components, such as rolling bearings. This has resulted in process innovations.

Carbonitriding of bearing steel has therefore experienced somewhat of a renaissance, as it facilitates higher levels of power density and temperature resistance. At the same time, low-distortion steels are being developed for lightweight construction, and modular heat treatment processes (e.g., nitriding and low-pressure carburizing) are being introduced to adapt processes more flexibly to different workpieces.

Progress has also been achieved when it comes to the furnace technologies themselves. New furnace designs combine multiple process steps in a single plant and make better use of energy. For example, pre-heating, heating up, and melting are combined in a single furnace shaft in modern shaft furnace designs. This makes maximum energy yield possible, thanks the smart geometry and burner technology. Due to the installation of these types of new melting furnaces, gas consumption and therefore energy costs can be reduced significantly.

In addition, compact furnace constructions are gaining in importance, as space-saving, modular furnaces enable integration in confined production environments, without compromising capacity or temperature homogeneity.

Finally, induction technology is also increasingly being used in heat treatment — for example for inductive hardening of complex components — as it combines precise local heating with high energy efficiency. Overall, technical progress aims at achieving higher product quality with lower side effects (e.g., distortion, energy consumption, scrappage).

Measures for Improving Energy Efficiency

In light of increasing energy costs and strict climate targets, energy efficiency in thermal processing plants is once again in the spotlight. Over the past five years, various measures have been established to reduce the energy consumption of furnaces and heat treatment processes.

Optimized Furnace Insulation and Construction

Manufacturers are increasingly relying on improved insulating materials and energy-efficient furnace constructions to minimize heat loss. State-of-the-art industrial furnaces have highly effective insulation and sophisticated flow guidance, meaning less unused energy escapes. This therefore significantly reduces the specific energy demand per processed piece.

Heat Recovery

Nowadays, unavoidable waste heat is better exploited. New technologies (e.g., high-temperature heat pumps or ORC systems) can raise waste heat to a usable temperature and guide it back into the process or use it for electricity generation. This waste heat recycling reduces the use of primary energy and, accordingly, emissions. McKinsey & Company (2022) estimates the global waste heat potential that can be exploited to be at least 3,100 TWh annually, which could mean savings of up to €140 billion (US$164 billion) per year if used in full. In practice, recuperators, regenerative burners, and heat exchangers are part of the standard equipment of many furnaces to reuse energy from hot exhaust gases for pre-heating processes.

More Efficient Burners and Process Control

Progress in burner technology also plays a role in achieving savings. Industrial gas burners currently operate with improved air pre-heating or flameless oxidation (FLOX) modes, which increase efficiency and reduce losses. Precise digital control systems (with PID controllers and recipe programs) also ensure that furnaces remain in the target temperature range with increased accuracy. Avoiding overshoots (overheating) in heating-up and cooling-down phases saves energy and shortens process times. Intelligent control algorithms and sensor technology ensure that the temperature distribution is more even, meaning fewer readjustments are required.

Modernizing and Replacing Old Plants

Many companies are investing in replacing outdated furnaces with new, energy-optimized systems. These types of modernization efforts — often funded by state energy efficiency programs — boost productivity and reduce energy consumption by double digits in no time. Retrofits (e.g., improved insulation, speed-controlled drives for fans, automatic door locks) also noticeably boost the efficiency of existing furnaces.

These measures pay off both economically (thanks to reduced operating costs) and environmentally (thanks to reduced emissions). Efficient thermal processing technology has therefore become a core concern for the industry.

Digitization and Automation in Thermal Processing Technology

Industry 4.0 has reached thermal processing technology over the last few years. Automation and digitization are now the most important drivers of growth in this sector. Specifically, a range of state-of-the-art technologies are used in furnaces and heat treatment systems.

IoT-Capable Furnaces and Interconnected Sensor Technology

New industrial furnaces are equipped with sensors (e.g., temperature, pressure, atmospheric composition, wear monitors) and communicate their operating data in real time. These types of smart furnaces enable the process to be continuously monitored and fine-tuned. The data gathered is evaluated in control systems, which boosts operating efficiency and reduces downtimes. For example, trends in temperature curves or burner parameters can provide early indication that maintenance is required. Operators can therefore achieve interruption-free production processes thanks to predictive maintenance.

Predictive Maintenance and Digital Twins

Instead of reactive maintenance, many companies rely on predictive maintenance. Upcoming plant failures can be predicted using machine learning from sensor data. Digital models (twins) also simulate the furnace behavior and facilitate parameter optimization, without interrupting real-time operation. According to a market analysis, these types of virtual simulations are used to plan preventative maintenance and optimize processes. This boosts plant availability and extends maintenance intervals.

Consistent Automation and Reliable Control Systems

Today, thermal processing plants use PLC/CS systems to automatically control operations and can coordinate multiple connected furnaces or burners centrally. State-of-the-art control systems meet high safety standards (e.g., according to EN 746-2 or ISO 13577 for burner safety), meaning that even complex plants can be operated in compliance with standards and fail safety. This trend toward safely automated thermal processing plants has been further advanced thanks to new standards and digital control technology, among other things.

Integration of AI and Autotuning Systems

The first AI-based optimization systems are being implemented to improve thermal processing in real time. Systems like this learn from process data and adapt parameters (e.g. furnace atmosphere, power control) automatically to further reduce energy consumption or throughput time.

Robots and Automation of Handling

Alongside furnace control itself, the material handling process is also increasingly being automated. In modern hardening plants and foundries, robots deal with the loading and unloading of furnaces and transport workpieces between process steps, thereby boosting process reliability and reproducibility. This reduces errors due to manual interventions and enables low-personnel or lights-out operating concepts.

Overall, digitization results in higher flexibility, quality, and availability in thermal processing technology. Companies that make use of heat treatment 4.0 can respond to new production requirements more quickly and operate their plants more cost-effectively as a whole. The industry is transitioning toward data-driven, intelligent systems that are transforming traditional furnaces into high-tech interconnected systems.

Developments in the Field of Sustainable and Environmentally Friendly Technologies

Against the backdrop of climate change and environmental requirements, thermal processing providers are increasingly promoting sustainable technologies. A key aim is to decarbonize industrial heating processes — in other words to drastically reduce CO₂ emissions and other pollutants. Multiple developments over the last few years should be highlighted here.

Electrification of Heating Processes

Wherever possible, fossil fuel-fired furnaces are being replaced by electric heating processes. Electric heat (e.g. induction furnaces, resistance heating furnaces, or electric arc furnaces) does not cause any direct emissions locally and can be operated practically CO₂-neutrally using green electricity. Electric high-temperature heat pumps, electric boilers, and furnaces are increasingly gaining in popularity, particularly for low temperature ranges or discontinuous processes.

However, there are challenges. In some industries, gas-fired furnaces are still more cost-effective due to higher electricity prices — even though electric furnaces often operate more efficiently. Although fully electric melting furnaces in the glass industry may be more energy-efficient, they cannot yet achieve the capacities of larger gas furnaces and may result in higher operating costs depending on the region. Nevertheless, the proportion of electric heat treatment systems is continuously rising, especially as the investment costs are often lower (no fuel storage, no exhaust gas cleaning required).

Hydrogen and Alternative Fuels

High hopes are resting on green hydrogen as a replacement for natural gas or oil in industrial furnaces. Hydrogen burns without producing any CO₂ if it originates from renewable sources — the only product that is created is water vapor. However, hydrogen requires a modified furnace design and safety precautions due to different combustion properties (faster flames, higher temperature peak). Nonetheless, initial pilot plants such as those in the steel and brick industry, successfully demonstrate operation with hydrogen burners. Ammonia is also being trialed as a storable hydrogen carrier (in particular in Japan) in order to provide carbon-neutral process heat.

Emission-Free Combustion Technologies

Regardless of the fuel, there is a focus on reducing harmful gases such as NOx. Technologies such as flameless oxidation (FLOX) and staged combustion drastically reduce NOx formation by smoothing combustion peaks. Some manufacturers are making their names as pioneers in low-emission technologies in furnace construction. Improved filter and afterburning systems are also being integrated to remove particles, VOC, and CO from exhaust gases. State-of-the-art thermal processing plants therefore often significantly fall below current limit values and minimize local air pollutants.

Energy Management and Renewable Integration

Sustainability is also reflected in plant energy management. Many companies are integrating their furnaces into energy recovery cycles or using excess heat to heat other plant components or buildings. Some heat treatment companies are investing in their own renewable energy sources (photovoltaics, wind) or are purchasing green electricity to lower the CO₂ footprint of their processes.

For example, in the aluminum recycling industry, AI systems (as mentioned above) are used to reduce the use of new aluminum and melt more scrap, which saves a significant amount of energy. These types of holistic approaches — closing the material cycle, using waste heat, employing green electricity — play a role in ensuring environmentally friendly thermal processing technology.

As a whole, the industry is making significant strides toward climate neutrality and resource conservation. Numerous providers and industrial companies have set voluntary targets or commitments to reduce their process-related emissions by large percentages by 2030 or 2040. The course is set in terms of technology (electric processes, hydrogen as an option, highly efficient furnaces) to make this transformation possible.

Regulatory Developments and Underlying Legal Conditions

The trends described are strongly impacted by laws and regulations. Over the last few years, legislators around the world have enacted an increasing number of rules which also impact thermal processing technology.

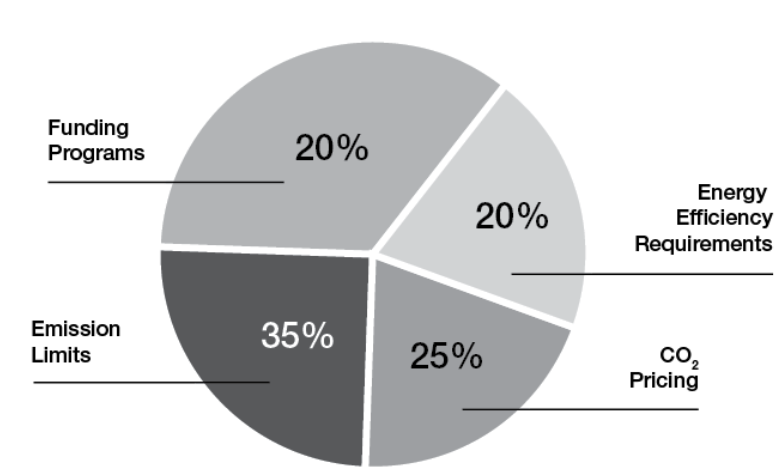

Environmental Regulations and Emission Limits

There are now strict limit values for exhaust gases from industrial furnaces (NOx, CO, particulate matter, etc.) in many regions. For example, the permitted emissions have been tightened up further in the EU with the Technical Instruction on Air Quality Control 2021 and the Industrial Emissions Directive. Manufacturers are responding to this with the low NOx technologies mentioned above as well as more efficient combustion in order to adhere to the strict environmental regulations. The permitted CO₂ emissions are also being limited indirectly — by such means as national CO₂ prices or emission trading schemes which make fossil fuels more expensive. This creates an economic incentive for switching over to more efficient or CO₂-free technologies (electric heat, H₂).

For example, China’s state “dual carbon” strategy aims at reaching peak CO₂ early and then becoming climate-neutral – which is pushing the local heat treatment industry to upgrade to energy-efficient and environmentally friendly plants quickly. Similar climate protection programs in Europe (Green Deal/Fit for 55) and the U.S. (Industrial Heat Shot, 85% emission reductions by 2035) exert pressure globally to make thermal processing plants greener.

Energy Efficiency Requirements and Promotion

Many countries have legal targets for reducing industrial energy consumption. For example, the Energy Efficiency Directive in the EU means large companies are obligated to carry out audits which often uncover potential for greater efficiency in thermal processing. Germany and other countries are funding investment in energy-efficient interdisciplinary technologies — explicitly including industrial furnaces.

Companies receive subsidies or tax breaks if they replace old plants with efficient ones or introduce utilization of waste heat. For example, in the case of Hattori in Japan, a state funding program helped it to finance the purchase a new melting furnace. This type of funding significantly speeds up the market penetration of state-of-the-art technologies.

Safety and Quality Standards

These underlying legal conditions not only relate to the environment, but also to safety and quality. The EN standards series 746 (or ISO 13577 et seqq.) for thermal processing plants has recently been updated to represent the current state of technology — for example with respect to the functional safety of burner controls. Operators are instructed to equip their plants according to these standards, which makes the use of advanced control technology necessary. In safety-critical industries (e.g., aerospace), standards and customer requirements also require each heat treatment process to be documented in detail (AMS2750 or Nadcap in heat treatment). This promotes digitization (for example electronic batch reports, traceable sensor technology calibrations) and ensures that new technologies operate reliably and in a reproducible manner.

All in all, regulations both put pressure on companies and create incentives: on the one hand, stricter laws force companies to make changes (any company which operates inefficiently or produces a high level of emissions, risks penalties or competitive disadvantages); on the other hand, funding programs mean that making the switch is easier. The thermal processing technology industry is current operating in an environment which is strongly influenced by climate and industrial policy objectives — and therefore responds with innovations to meet these objectives.

Market Growth and Predictions for the Years Ahead

The thermal processing technology market is characterized by solid growth thanks to the above-mentioned trends. Around the world, the market volume of industrial furnaces and heat treatment systems is expected to grow further. According to a current analysis (Future Market Insights), the global market grew to a volume of around USD 10.26 billion in 2024 and is expected to grow to above USD 17.1 billion by 2035; this corresponds to an average annual growth rate of around 4.8% (2025–2035).

Industries and regions: almost all user industries contribute to market growth, in particular the automotive industry. Significant markets such as Europe and North America are experiencing somewhat more moderate growth but are increasingly carrying out high-tech upgrades to existing plants.

Market character and outlook: the thermal processing technology market is highly diversified, spanning large continuous furnaces for mass production to specialized laboratory furnaces. Customized solutions are gaining in importance, as manufacturers are increasingly having furnaces tailored precisely to their process requirements.

Conclusion

The thermal processing industry has noticeably changed over the last five years. Modern industrial furnaces and heat treatment processes are more efficient, digitally networked, and significantly more environmentally friendly than their predecessors. Companies are investing in energy-efficient, automated plants to both reduce costs as well as meet regulatory and climate-relevant requirements. These trends will continue over the upcoming years.

Further market growth can be expected, while the technologies also evolve toward sustainability and smart manufacturing. The combination of innovation and adaptability mean that thermal processing technology will secure a central position in the industrial value chain in the future.

References

European Commission. 2025. EU Green Deal Industrial Heat Shot: Achieving 85% Emissions Reductions by 2035. March 2025. https://ec.europa.eu/green-deal-industrial-heat-shot.

Foundry-Planet. 2024. THERMPROCESS China 2024 – High Potential for the Global Thermal Process Industry on the Chinese Sales Market. February 17, 2024. https://www.foundry-planet.com/d/thermprocess-china-2024-high-potential-for-the-global-thermal-process-industry-on-the-chinese-sales-market/.

Future Market Insights, Inc. 2025. Industrial Furnace Market to Reach USD 17,108.4 Million by 2035, Driven by Energy Efficiency and Regional Growth. January 17, 2025. GlobeNewswire. https://www.globenewswire.com/news-release/2025/01/17/3011338/0/en/Industrial-Furnace-Market-to-Reach-USD-17-108-4-million-by-2035-Driven-by-Energy-Efficiency-and-Regional-Growth-Future-Market-Insights-Inc.html.

German Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection (BMUV). 2021. Technical Instructions on Air Quality Control (TA Luft). December 1, 2021. https://www.bmuv.de/en/topics/air/air-quality-control/technical-instructions-on-air-quality-control-ta-luft.

Kelly, Brian, and Jeff Rafter. 2024. “Hydrogen Basics for Industrial Burners.” Thermal Processing, January 2024. https://www.thermalprocessing.com/hydrogen-basics-for-industrial-burners/.

Leicher, Jörg, Anne Giese, and Christoph Wieland. 2024. “Electrification or Hydrogen? The Challenge of Decarbonizing Industrial (HighTemperature) Process Heat.” J 7 (4): 439–456. https://doi.org/10.3390/j7040026

McKinsey & Company. 2022. Waste Not: Unlocking the Potential of Waste Heat Recovery. August 24, 2022. https://www.mckinsey.com/capabilities/sustainability/our-insights/waste-not-unlocking-the-potential-of-waste-heat-recovery.

Neal Systems Incorporated. n.d. Top 10 Tips to Improve Efficiency in Heat Treatment Processes with Eurotherm. Accessed July 14, 2025. https://www.nealsystems.com/top-10-tips-to-improve-efficiency-in-heat-treatment-processes-with-eurotherm/

New Energy and Industrial Technology Development Organization (NEDO). 2023. Decarbonization of Thermal Processes in Manufacturing. March 28, 2023. https://green-innovation.nedo.go.jp/en/project/thermal-processes-in-manufacturing/.

PROZESSWÄRME. 2020. Wärmebehandlung & HärtereiPraxis: PROZESSWÄRME 5/2020. September 9, 2020. https://prozesswaerme.net/forschung/09-09-2020-prozesswaerme-52020-waermebehandlung-haertereipraxis/.

StrikoWestofen. 2019. First StrikoMelter for Hattori Diecast. April 2019. https://www.strikowestofen.com/de-de/whats-new/strikowestofen-case-studies/first-strikomelter-for-hattori-diecast.

About The Author:

Market Segment Manager

JUMO

Over the last eight years, Christoph Bollgen has made an incredible journey from a college teaching assistant to the Market Segment manager at JUMO Process Control. Along the way, Christoph earned a bachelor’s degree in automation and robotics from the University of Applied Science Fulda, Germany, and received a master’s degree in industrial engineering from the University of Texas in Arlington. After joining JUMO, Christoph successfully participated in the CQI-9 Process Auditor training in 2019 and in the 2019 SECO/WARWICK Heat Treatment 4.0 Seminar, gaining expertise about topics such as theoretical and practical issues of heat treatment 4.0 concerning aircraft, automotive, mass production, and hardening industries.

Christoph was also an honoree in Heat Treat Today’s 40 Under 40 Class of 2024.

For more information: Contact Christoph Bollgen at christoph.bollgen@jumo.net.