An aerospace manufacturer is expanding with a vacuum furnace for brazing fuel system components for aircraft engines. The single-chamber vacuum furnace has a molybdenum heating chamber and gas cooling up to 1.5 bar abs.

SECO/WARWICK, which has U.S. locations, spent years in collaboration with this manufacturer to ensure it met their high precision needs.

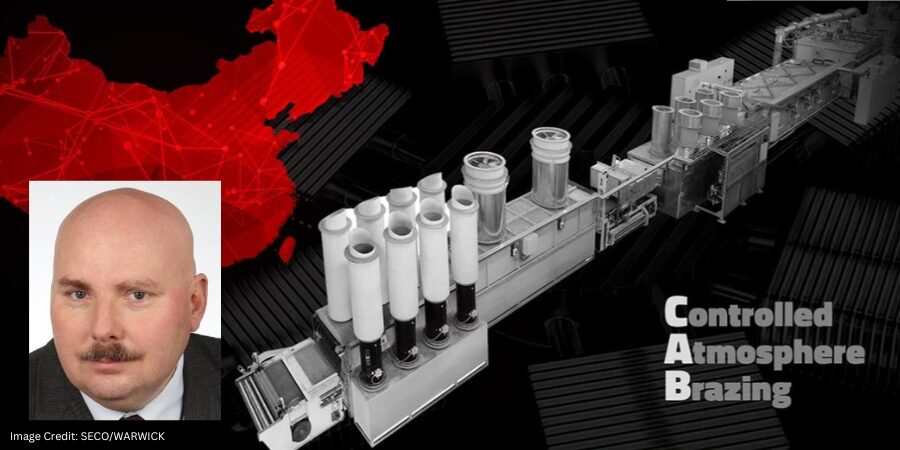

Vice President of Business of the Vacuum Furnace Segment

SECO/WARWICK

“This partner is one of the most specialized production centers in Europe when it comes to precision elements of fuel installations for aircraft engines. The fact that they once again chose SECO/WARWICK technology is the highest form of appreciation,” says Maciej Korecki, vice president of the Vacuum Segment at SECO/WARWICK. “Our solution is the result of technical dialogue, adaptation to the client’s requirements and optimization for process cleanliness, high vacuum, and the size of the parts to be manufactured.”

The vacuum furnace has been significantly modified to meet the client’s specific technological requirements. It includes a molybdenum heating chamber with shield insulation, which reduces heat loss and provides purity for thermal processes. A temperature uniformity of ±6°C (±11°F) ensures uniform conditions throughout the heating zone, which is crucial when brazing tubular components for fuel systems.

The device’s vacuum system, built on mechanical pumps, a roots pump, and a diffusion pump, maintains a stable and deep operating vacuum at the level of 10⁻⁴ to 10⁻5 mbar. A partial pressure system for protective gases (hydrogen, argon) has also been implemented, preventing the sublimation of alloying elements and protecting the quality of the load. A dew point sensor installed at the gas inlet secures the process against contamination from the atmosphere.

The new furnace will provide full production capabilities, handling an increased number of components for fuel systems in aircraft engines. Its implementation will have an impact on the efficiency, quality, and stability of brazing processes.

Press release is available in its original form here.