18 News Chatter To Keep You Current

Heat Treat Today offers News Chatter, a feature highlighting representative moves, transactions, and kudos from around the industry. Enjoy these 18 news items.

Equipment

- A Canadian automotive components manufacturer recently expanded its operations with an electrically heated small batch oven to be used for curing arts. The small batch oven was manufactured by Wisconsin Oven, designed to utilize combination airflow to maximum heating rates of 650°F and temperature uniformity.

- With the successful conversion to a four-stand finishing mill, Henan Yirui New Materials Technology Co, Ltd, officially began production. SMS Group converted an existing hot rolling mill into a tandem finishing mill by adding three new finishing mill stands, developed for refurbishing and integrating components.

- KALLER, a manufacturer of gas springs and gas hydraulic systems based in Sweden, recently launched its fully automated line of hardening furnaces for surface coatings on gas springs. The hardening systems were supplied by Ipsen International.

Source: Wisconsin Oven

Source: LinkedIn

L-R: Rüdiger Roger Wiechmann, Project Manager at SMS group, with Zheng Guoqiang, Project Manager at Henan Mingtai Aluminium).

Source: SMS Group

Company & Personnel

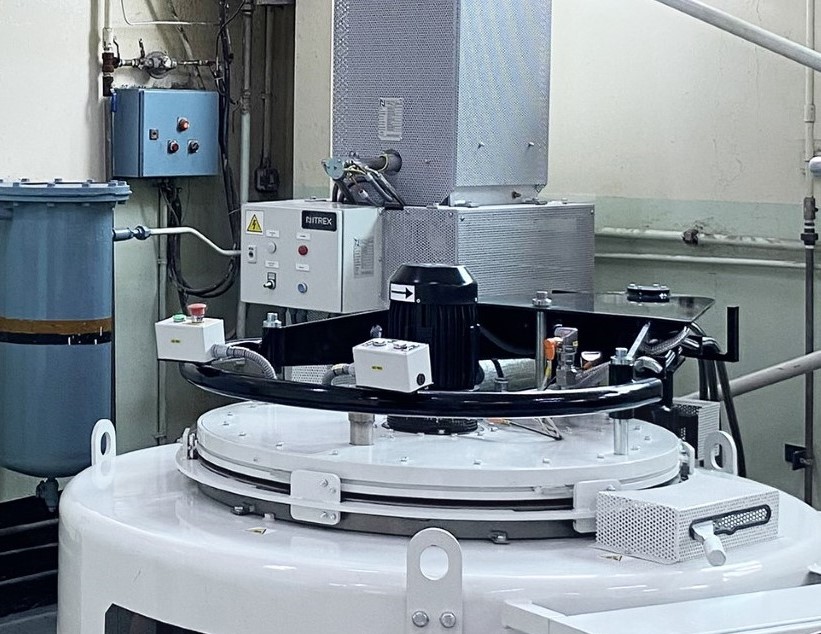

- Steve Fuller has joined the team at Nitrex HTS as the new plant general manager at their Michigan location. He brings 45 years of experience in commercial heat treating, machine tool manufacturing, fabrication, quality management, and more.

- Bobby Boom, Tim Litchauer, and Wade Sholmire, have been added to the Superheat team as business development managers. Wade is the new National BDM, Tim will oversee the Greater Houston Area, and Bobby will manage the Southeast Texas, Louisiana, and Arkansas regions.

- Chris Martin has been promoted to regional sales manager for the Southeast by Ipsen. Chris will be responsible for leading a team of seven that includes six field service engineers and one service administrator.

- Adam Woelber has been promoted to manager of aftermarket parts and service at AFC-Holcroft.

- Ethan Castle has been appointed the St. Louis plant manager for Paulo Heat Treating, Brazing, and Metal Finishing, recognized for his leadership, technical capability, and mentoring role, in addition to representing the company within the North American Diecasting Association and National Tooling and Machining Association. Ethan has also been named to Heat Treat Today‘s 40 Under 40 Class of 2024.

- Gary Doyon has stepped down from his role as CEO of Inductotherm Group, after 15 years in the position and 38 years with the company. Mick Nallen and Satyen Prabhu have taken as co‐leaders at the company, which provides thermal processing technologies. Mr. Doyon will remain actively involved with the company, assisting with specific operational needs of other businesses owned by the Rowan family and pursuing new business avenues and opportunities for the Inductotherm Group.

- Ipsen USA has launched its Field Service Engineer Academy, designed to be a 20-week in-depth program with classroom training and experience in the field with veteran service technicians. Darci Johnson, program and transformation manager at the company, is leading the implementation of the FSE Academy. Content will focus on the fundamentals of vacuum furnace repair.

- Industrial furnace equipment manufacturer Gasbarre welcomed Dan Hill as product development manager; he will be based at the company’s Livonia, Michigan, facility. A licensed professional engineer, Dan brings a diverse background in capital equipment, spanning material handling, control systems, boilers and furnaces, combustion systems, and industrial washing/deburring equipment.

- The U.S. Navy recently selected StandardAero to serve as its engine depot-level repair prime contractor to perform Rolls-Royce T56-A-427A engine MRO services, supporting the Navy’s fleet of E-2D Advanced Hawkeye aircraft. The aerospace aftermarket service supplier has also announced that Turkish and European Boeing 737 Operator Corendon Airlines has extended its contract for the support of CFM LEAP-18 engines.

- Ipsen USA recently announced the formal launch of its Service HUB model, marking a significant shift in how the company delivers customer service and support across the United States. The program has been under the direction of Geoffrey Somary, the company’s global CEO. Currently being led by John Dykstra, chief service officer, the HUBs now provide services across a large portion of the Midwest and Southeastern United States. Lu Chouraki, manager of business development, is leading the implementation of the HUBs.

Plant General Manager

Nitrex HTS

Source: Nitrex

National Business Development Manager

Superheat

Source: Superheat

Business Development Manager for the Greater Houston Area

Superheat

Source: Superheat

Business Development Manager for Southeast Texas, Louisiana, and Arkansas

Superheat

Source: Superheat

Regional Service Manager for the Southeast

Ipsen

Source: Ipsen

Manager of Aftermarket Parts and Service

AFC-Holcroft

Source: AFC-Holcroft

St Louis Plant Manager

Source: Paulo

Retiring CEO

Inductotherm Group

Source: Inductotherm Group

Source: Ipsen USA

Product Development Manager

Gasbarre

Source: Gasbarre

Kudos

- James Wellborn, gas nitride manager at Advanced Heat Treat Corp, celebrates 25 years with the company.

- Patricia Miller, director of technical services at Uddeholm, has been named the Technical Committee Member of the Year by North American Die Casting Association (NADCA).

- Denise Blaubach, who is known as the resident flow meter assembly expert at UPC-Marathon in Wisconsin, recently celebrated 35 years with the company.

- Constellium today announced it has achieved Aluminum Stewardship Initiative (ASI) Performance Standard Certification for all its operations, and for its corporate office in Paris.

- Sinosteel E&T and Tenova have successfully completed the performance test for the ENERGIRON DRI Plant at the Baosteel Zhanjiang site in China. The sustainable hydrogen-based 1,000,000 tonnes/year ENERGIRON Direct Reduction (DR) plant demonstrated the nominal production of DRI, reducing carbon dioxide emissions and marking a significant step in the green steel industry.

Gas Nitride Manager

Advanced Heat Treat Corp

Source: Advanced Heat Treat Corporation

Director of Technical Services

Uddeholm

Source: Uddeholm

Source: UPC-Marathon

Source: Tenova

Find Heat Treating Products And Services When You Search On Heat Treat Buyers Guide.Com

18 News Chatter To Keep You Current Read More »