Optimizing Your Induction Heating System

Whether you need insight on enhancing your energy utilization, managing induction systems (troubleshooting), or prolonging equipment longevity, today’s Technical Tuesday original content feature will keep you well-informed.

Heat Treat Today has coalesced technical information across articles from key experts, including tips to improve your energy efficiency, a walk-through guide for troubleshooting your induction system, and ten practical tips for improving your equipment longevity.

Induction and Sustainability Tips Part 2: Efficient Power

As energy efficiency becomes a driving force in modern heat treating, manufacturers are turning to smarter induction technologies to cut waste and lower costs. In this second installment of Heat Treat Today’s sustainability series, explore how AC-to-DC conversion, intelligent power feedback systems, and advanced diagnostics can transform your induction heating setup into a cleaner, more consistent, and cost-effective process.

“Furthermore, transformers operate at optimal efficiency when under a reduced load – i.e., less than 70% output in steady-state heating – rather than ramping up to the full operating temperature. Another advantage of the DC-type transformer is that its operating power factor is very close to 1.0, which lowers the utility company’s calculation of peak demand surcharges.”

Read the full article here: Induction and Sustainability Tips Part 2: Efficient Power

10 Steps To Troubleshoot Your Induction System

Facing erratic heating, poor consistency, or unexpected shutdowns in your induction system? This comprehensive guide walks heat‑treat operators through a ten‑step diagnostic framework for identifying and resolving common induction issues.

Source: Contour Hardening, Inc.

“The induction process involves many characteristics such as: position of the piece within the induction coil, load positions, cooling positions, cycle times, applied electric power, and others. It is important that the professional can identify the failure and the particular situation at the moment in which it is occurring.

On some occasions, the failures are not evident and therefore it is essential to analyze the part that has been treated. This analysis can be key to understanding situations such as poor depth due to electrical power or decrease in output frequency, among other possible scenarios.”

Read the full article here: 10 Steps To Troubleshoot Your Induction System

New and Improved Tips for Induction Equipment Longevity

Heat treaters are always looking for ways to extend the life of their induction tools, but what methods are proven maintenance strategies? Focusing on the durability of coils, bus bars, inductors, and quench components, this technical article will give you practical and reliable tips to promote longevity in your equipment.

“More than coils — When working to optimize the life of induction equipment, don’t focus solely on the coils. Bus bars, inductors, and quenching equipment are also key to success.

Austenitic stainless steel — Use austenitic stainless steel for fasteners, fittings, and hose clamps, and remember, non-ferrous is the way to go.

CNC machining — Manufacturing with a 5-axis CNC machine ensures quality and consistency.

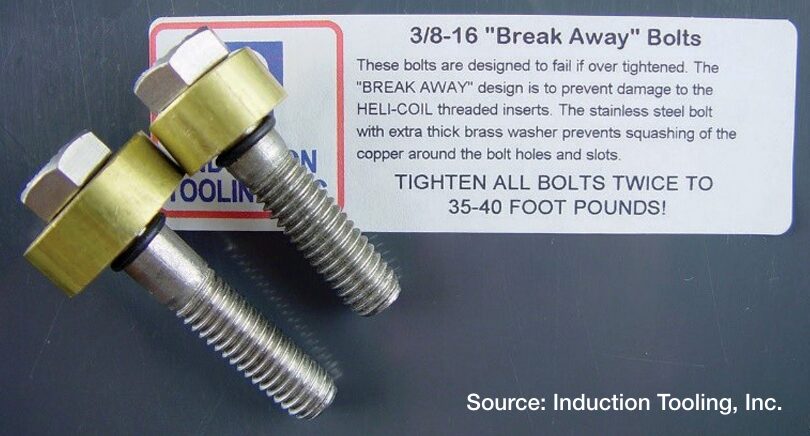

“Break-Away” bolts — For fasteners, use “Break-Away” bolts on contact surfaces. These bolts are designed to fail beneath the washer if they are overtightened, a design that prevents damage to the threaded insert inside the copper contact.”

Read the full article here: New and Improved Tips for Induction Equipment Longevity

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Optimizing Your Induction Heating System Read More »