A heat treating services and metallurgical solutions company recently announced the arrival of three new gas nitride units at its corporate headquarters, doubling the gas nitriding capacity at this location and allowing the company to expand its UltraGlow® gas nitriding and UltraOx® surface treatment solutions.

The three new gas nitride units at Advanced Heat Treat Corp’s Waterloo, Iowa, corporate facility vary in size, allowing for the accommodation of various industries and applications including, but not limited to: aerospace, automotive, oil and energy, agriculture, construction, and firearms.

One nitride unit will be operational this month, and the additional two units will be running in February. AHT also has plans to design and build an additional unit later in 2019.

“I’m excited on many accounts,” said AHT President, Mikel Woods. “One, we’re adding capacity/back-up to an already growing agriculture/construction market. Two, we have plans to add a new Nadcap process in order to expand further into the aerospace market and meet our customer requirements/requests. And three, we’re gearing up to go even bigger in 2019 with additional equipment.”

The new units will house AHT’s UltraGlow Gas Nitriding and UltraOx services, commonly used in manufacturing to prevent corrosion and improve wear resistance.

“UltraOx is rapidly replacing processes like QPQ/salt bath, chrome plating, and nickel plating; therefore, it was pivotal for us to invest in more equipment so that we can accommodate the growing demand and continue to provide our customers with the quality and service they have come to expect from AHT,” said Woods.

AHT is currently Nadcap accredited for ion nitriding at their corporate location, but with the additional capacity, AHT plans to gain accreditation in gas nitriding by this summer as well. The additional Nadcap accreditation will help AHT to accommodate additional aerospace needs and grow their UltraGlow gas nitriding service.

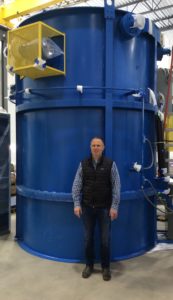

Photo caption (main): John Ludeman, AHT Quality and Continuous Improvement Manager; Dan Sager, Assistant Operations Manager; Jill Manning, AHT accountant; Carlos Urzagaste, AHT maintenance supervisor