![]() Technology is ever evolving. Will you be able to keep up with all the new developments? Discover the tech trends these heat treat industry leaders are excited about and how they will impact you and your company.

Technology is ever evolving. Will you be able to keep up with all the new developments? Discover the tech trends these heat treat industry leaders are excited about and how they will impact you and your company.

This article first appeared in Heat Treat Today’s February 2022 Air & Atmosphere Furnace Systems print edition.

AFC-Holcroft LLC

Sales Engineer

AFC-Holcroft

Heat treaters are taking part in sustainability initiatives aimed at reducing greenhouse gases and achieving carbon neutrality. Whether larger or smaller-scale, commercial or captive, customers are seeking ongoing collaboration and ultimately equipment solutions aimed at sustainability. While much of these initiatives remain targets rather than requirements, there is steady momentum commercially, politically, and socially for them. Understanding the targets with respect to your business’ goals — and the technologies available to meet them — will help determine appropriate strategic plans. Specific trends in this context include:

Trend 1:

Latest high efficiency burner technologies such as our Aichelin Group’s Noxmat products are continually growing in popularity. Moreover, secondary energy recovery systems are used for preheating products or external processes. These solutions all improve thermal efficiency, thereby reducing overall carbon footprint.

Trend 2:

Although natural gas heating still has a sizeable operating cost advantage, additional users are instead opting for electric heating systems on new equipment and conversions of existing equipment. As electric utility providers add renewable energy options for business customers, the carbon footprint for heating can be reduced or even net zero.

Trend 3:

AFC-Holcroft has long been an advocate of molten salt quenchants for superior distortion control and for the improved properties of austempered materials they can also produce. Much to do with those same thermal stability properties, these molten salt baths can be used for years without deteriorating whereby only salt drag out needs to be made up in the quench tanks. Yet with modern salt reclamation systems, the salt drag out on parts and tooling is quickly recaptured in a post washer where it can be separated and recycled back into the very same quench tank over and over.

Air Products

Heat Treat Gas Smart Monitoring: Maximizes Productivity and Safety with Advanced Monitoring Systems

Now, more than ever, technology needs to come into play to maximize efficiency in the workplace and monitor key indicators on production lines. This includes remote monitoring, using sensors and wireless communications technology to track process efficiency, production rates, machine settings, and parameters. It allows manufacturers to see whether processes are running as smoothly as they could be, or if there is a way to boost efficiency. Using real time and historical data allows optimization of production processes, saving time and money by providing the information needed to minimize gas and utility usage while ensuring product quality remains high. In addition, a visual overview of how the equipment is performing helps to guard against unsafe practices and allows for preventative maintenance processes to be carried out before operational failures occur.

Now, more than ever, technology needs to come into play to maximize efficiency in the workplace and monitor key indicators on production lines. This includes remote monitoring, using sensors and wireless communications technology to track process efficiency, production rates, machine settings, and parameters. It allows manufacturers to see whether processes are running as smoothly as they could be, or if there is a way to boost efficiency. Using real time and historical data allows optimization of production processes, saving time and money by providing the information needed to minimize gas and utility usage while ensuring product quality remains high. In addition, a visual overview of how the equipment is performing helps to guard against unsafe practices and allows for preventative maintenance processes to be carried out before operational failures occur.

The Air Products Process Intelligence™ offering includes a cloud-based process optimization system developed for the metals processing industry. This Industry 4.0 tool enables recording and analysis of the production parameters and is linked to operational results, facilitating process optimization, and product quality improvement. Integrated with thermodynamic calculations, field experience, and documentation features, the tool provides process engineers with extended capabilities to manage production and support process troubleshooting. This will also help manufacturers comply with requirements such as CQI-9 and Nadcap.

Learn more about Air Products Process Intelligence™ at www.airproducts.com/APSmart.

Gasbarre Thermal Processing Systems

The team at Gasbarre is always looking to improve the designs and technology of our equipment.

President, Industrial Furnace Systems

Gasbarre Thermal Processing Systems

Advancements in heating systems, insulation packages, and controls are key to improving efficiency and process control. With the updates to these systems, it is common for new equipment to be justified on utility savings alone. Control systems are upgraded for predictive and preventative maintenance activities, precise process control, and conformance to the latest CQI-9 and AMS-2750 standards.

Like it or not, companies are being forced to look for ways to reduce their carbon footprint and become more energy efficient in their manufacturing processes. Gasbarre has identified ways to consider improving your operation of your continuous furnace system. We can integrate sensors and controls into almost all aspects of an existing or new furnace to give you the ability to monitor and manage your inputs. This includes production speed, cooling water, natural gas, electricity, and atmosphere. Converting a furnace to run hydrogen and nitrogen atmosphere versus generating atmospheres (i.e., endothermic or exothermic generators) will greatly reduce your carbon footprint, while helping to reduce on-site utility and maintenance costs.

Gasbarre’s continuous vacuum furnace system takes energy efficiency and furnace performance to a new level. Vacuum furnace systems off er many advantages over conventional atmosphere furnace systems. We discuss this in terms of the 4-Es:

1. Effects on material properties due to the pure environment of the furnace

2. Energy efficiency due to its ability to be turned on and off when not in use, limited furnace conditioning, and focused heating system

3. Environmentally friendly as there are little to no emissions, either zero or more efficient atmosphere consumption, and no atmosphere burn-off requirements

4. Elevated temperatures can be achieved supporting more process flexibility and improved cycle times

Gasbarre Thermal Processing Systems has been designing and manufacturing continuous furnace systems for nearly 50 years. As a leading manufacturer of both atmosphere and vacuum continuous furnace systems, Gasbarre has the knowledge and expertise to help drive your success now and into the future.

Noble Industrial Furnace

The Latest in Continuous Furnace Systems from Noble Industrial Furnace

In recent years Noble Industrial Furnace manufactured extensive continuous furnace lines for customers in New England, along the East Coast, and in the Midwest.

Our gas-fired or electric tube furnace projects included burnout (800–1450°F), hardening (1600–2100°F), and tempering (300–1200°F) process lines with material continuously running through multiple furnaces. Silicon carbide or alloy tubes strategically positioned within the proportionally dimensioned multi-zoned furnaces allowed for extremely tight temperature control and uniformity. Additional components in the line included chillers, cooling dies, and temperature-controlled nitrogen.

Noble delivered numerous gas-fired indexing belt burnout furnaces (800–1450°F) heated with high velocity burners. Design allows for parts to automatically index through the load station, burnout chamber, and cooling and unload station with necessary temperature sensing and data logging on individual parts and/or batches.

Traditionally designed continuous belt furnaces (600–1900°F) both electric and gas-fired, included options such as internal stainless steel shrouding, flame curtain or doors, forced air cooling or drop chute quench.

Control systems for the equipment met industry specific and customer required standards and integrations with PLC’s, HMI’s, controllers, and related components from leading manufacturers, including Allen Bradley, Honeywell, Yokogawa, and Eurotherm.

Noble has positioned itself for continuous growth in our industry for decades to come.

Yokogawa

Digital Transformation Enhances High Temperature Fan Bearing Monitoring

Maintaining reliable performance of furnace fans is critical to the heat-treating process; however, these fans are vulnerable to failures which can be difficult to predict. Increasing vibration in motor bearings is most commonly the first sign of a problem. Running the fans at the fringes of their specified operating ranges is a typical root cause. Temperature and vibration levels can be monitored either by handheld measurement devices or via sensors. Key challenges for heat-treat operators include the ability to efficiently maintain records of temperature and vibration data, determine trends in the data, and accurately predict problems before they arise.

Digital transformation and IIoT technologies can be quite beneficial to the monitoring and maintenance strategies for these furnace fans and other assets, especially those that are manually monitored or unmonitored. The first step is adding wireless sensors to regularly gather data about the equipment status. For process heating fans, vibration and surface temperature sensors are most beneficial and can be installed very easily with magnetic mounts. For other equipment and processes, temperature and pressure are among the additional measurements that are available. Data from these devices can be sent to on-premise systems, cloud-based systems, or both for visualization and analysis. This is where the real value comes into play, as these systems can provide early anomaly detection that enables operators to address equipment issues before they interrupt the process, impact the batch quality, or result in expensive repairs. Taking it a step further, artificial intelligence (AI) and machine learning (ML) algorithms can “learn” the normal equipment operating conditions, detect signs of problems very early in their development, and predict failures. These enable a more efficient condition-based maintenance process, which can considerably reduce facility downtime and operating costs.

Yokogawa’s Sushi Sensor solution exemplifies this technology. Learn more about the Sushi Sensor solution by visiting https://www.yokogawa.com/us/solutions/products-platforms/field-instruments/sushi-sensor-e/#Details .

Quaker Houghton

Aqua-Quench™ 260 solves distortion and residual stress issues in aluminum quenching.

Aqua-Quench™ 260 is a readily available AMS 3025 Type I certified quenchant, ideal to quench difficult aluminum parts. This product is used throughout the world in aerospace, automotive, and transportation to control distortion and residual stress in forgings, extrusions, castings, and plates.

Engine components are heat treated for wear and durability. Aircraft components are heat treated for strength and fracture toughness. Even bicycle frames are heat treated for strength, lightness, and durability. In each case, control of distortion and residual stresses are critical to efficient manufacture and long life of the product. By far the largest source of problems for heat treaters is distortion of parts after heat treatment.

Aqua-Quench™ 260 and Aqua-Quench™ 251 polymer quenchants are used in the industry to control and minimize the distortion occurring during the quenching of aluminum. Typically, these quenchants are governed by AMS 3025, and are either Type I (Aqua-Quench™ 260) or Type II (Aqua-Quench™ 251). Type I quenchants are single polyalkylene glycol polymers, while Type II quenchants are multiple molecular weight polyalkylene glycol polymers (PAG). Each offers different benefits. Because of the higher molecular weight of the Type II PAG quenchants, lower concentrations can be used.

For additional information, contact your local Quaker Houghton representative, or visit www.QuakerHoughton.com.

Idemitsu Lubricants America

Senior Key Account Manager

Idemitsu Lubricants America

Many commercial and captive heat treaters have a common problem with part cleanliness. Whether the post quench wash is a spray dunk cabinet or a spray washer, the use of the proper alkaline cleaner is critical to obtaining clean parts that meet or exceed expectations.

There are two basic types of cleaners: cleaners that emulsify the quench oil and those that split the quench oil. In the typical spray dunk washer, the load enters the washer and is then immersed and agitated. This agitation forms a mechanical emulsion as the cleaner removes the quench oil from the parts.

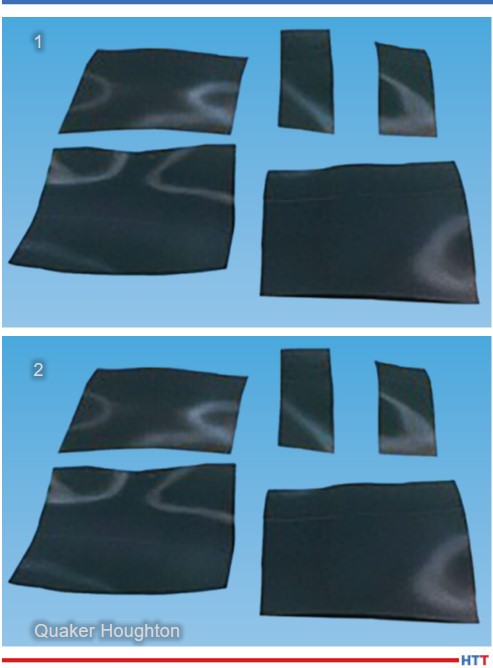

The next step is for the cleaner to enter a quiescent stage to allow the oil to break away from the mechanical emulsion and float to the top of the cleaner tank. At this point the floating oil is moved via a spray or air knife to a skimming chamber and the oil is brought up through the now oil-free surface into the spray chamber. A cleaner forming a chemical emulsion will combine the quench oil and cleaner into a single emulsion that is then sprayed onto the load. This redeposits the oil back onto the load. When the load exits the washer, the deposition of the oil onto the load is not obvious. However, when the load exits temper and the water portion of the emulsion and the oil have evaporated, the deposition of the oil is obvious. This redepositing of oil can be seen in the image below.

The same phenomena can occur in multistage belt and spray washers as well. In these continuous washers, the constant agitation from the spray creates a mechanical emulsion that does not allow the oil to separate out of the cleaner. In short, to optimize any post quench washer system the alkaline cleaner should not emulsify the quench oil. Instead, the oil should be allowed to float to the surface in a quiescent tank to be removed via a skimmer. The alkaline builders should also be liquid instead of a powder to eliminate clogged spray nozzles and housekeeping issues.

Honeywell

Enabled Combustion for the Heat Treat Market

In most heat treat processes, performance data gets trapped at the equipment level. To catch alerts or be aware of problems, a plant worker usually needs to physically stand next to the equipment. That’s impractical when organizations are under pressure to be more productive. Owners and operators know that to maximize productivity, they need to minimize unplanned downtime that can result in tens of thousands of dollars of lost revenue per hour. To this end, they need production and process systems that operate in a smart, efficient, and sustainable manner.

With diminishing numbers of combustion specialists, rising energy costs, reduced profit margins, and increased demand for better product quality, manufacturers with thermal processing assets are striving to increase productivity and reduce operating expenses.

Today, heat processing operations can harness the power of connectivity and information sharing to transform their operations. They can use connectable control devices and next generation control systems to capture critical, real-time process information and provide insight into the state of their thermal processes.

One such connected solution is Honeywell’s Thermal IQ. Part of Honeywell’s cyber-secure portfolio, Thermal IQ turns data into actionable insight so that users can optimize operations, predict equipment or process failures, and prevent unplanned downtime.

Remote monitoring enables organizations to closely monitor the operation of thermal processes, see real-time and trending data, and receive alerts when critical parameters stray outside normal limits. Meanwhile, users can maximize their thermal intelligence quotient by connecting everyone from management to maintenance group with insights that drive smarter decisions.

The result is that companies must no longer wait for faults or failures that can lead to shutdowns — instead, they can enable themselves to get ahead of trouble and take proactive steps to maximize uptime, productivity, and profitability.

Kanthal

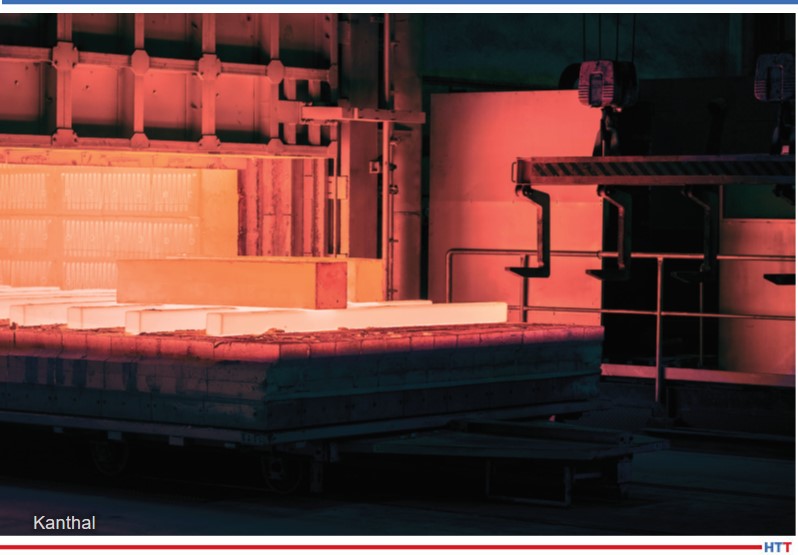

Electric heating helps steel industry fight climate change.

Sales Area Manager

Kanthal

To achieve its goal of fossil-free steel, the industry must stop using fossil fuels for its own heating processes. Electric heating is an existing alternative that has become increasingly attractive considering the growing focus on climate change. Electric heating is highly efficient, provides precise temperature control, and can remove carbon dioxide emissions completely when used with renewable electricity.

Steel is an essential material for the modern world, but it is also a major source of greenhouse gases. Today’s iron and steel industry accounts for six percent of global carbon dioxide emissions and eight percent of energy-related emissions, according to researchers at Columbia University’s Center on Global Energy Policy. The American iron and steel industry alone accounts for 62.1 million metric tons of direct carbon dioxide equivalent emissions annually, according to the U.S. Environmental Protection Agency.

“Electric heating can help the steel industry reduce its emissions while achieving high efficiency,” said Jon Hartmayer, sales area manager, NAFTA, at Kanthal. “If you use renewable electricity, you can get down to zero carbon dioxide emissions. Electric heating also removes emissions of nitrogen oxide and sulfur dioxide completely.”

A common misconception is that electric heat cannot create high enough temperatures, but that is not true. “Electrification gives a very high efficiency of up to 95 percent, with temperatures up to 3362°F (1850°C),” Hartmayer says. “Advanced control systems also allow you to get a precise temperature control, plus or minus one degree Celsius (+/- 1.8°F), while electricity provides a safer, cleaner and quieter production environment.”

One steel company that has experienced the benefits of electric heating is Ovako, which has collaborated with Kanthal to electrify 14 of its heat-treatment furnaces in its plants in Sweden. The results have been excellent.

“The estimated carbon dioxide savings are about 1,400 to 2,000 tons per year per furnace,” Hartmayer says. “The electrification has also created a more stable production that has significantly reduced daily maintenance.”

CODINA

The CODINA Technical Team is involved in analyzing and studying ways to improve the lifetime of our belts to keep each industrial application functioning properly.

Companies using mesh belt furnaces are forced to change the mesh belts time after time due to the degradation from the service done. Finding ways to extend the lifetime of a mesh belt will be directly linked to a cost reduction of the operation and maintenance of the furnaces.

The CODINA Technical Team defines mesh belts as “the mirror of the furnace,” since it is the only part going in and out. Understanding what the belt is showing and reporting that observation — during the operation — can be helpful to elongate the lifetime and function of the mesh belt.

For that purpose, the CODINA Technical Team, with experience of more than 50 years, suggests the following tips to extend, as much as possible, the lifetime and service of a mesh belt:

For that purpose, the CODINA Technical Team, with experience of more than 50 years, suggests the following tips to extend, as much as possible, the lifetime and service of a mesh belt:

1. Check all the conveyor guides and cylinders (driving, return, tensioning, supports, etc.). All the cylinders must be at 90° in respect to the middle line of the conveyor and perfectly parallel to them.

2. Review the supports or sliding guides of the furnace. Ensure there are no sharp edges or elements that could rub and damage the belt.

3. Keep the furnace clean and free of parts that could stack the product and affect the mesh belt.

4. Ensure the temperature inside the furnace is always homogenous.

5. Maintain a homogeneous product loading (in terms of weight and dimension) during all belt lifetime and operation. Non-homogeneous loading on width and length will end with a non-desired deformation and a lifetime reduction.

6. Pay attention to the deformation and the elongation of the mesh belt during all mesh belt service. Unusual deformations and elongations give information about possible improper set ups or higher pressures on the traction systems.

7. Check the belt alignment continuously and if necessary, rectify alignment where appropriate.

Super Systems, Inc.

The Latest Developments & Technical Trends in Controls & Instrumentation

President

Super Systems, Inc.

The thermal processing industry continues to push forward with technology in the areas of controls and instrumentation to ensure the proper thermal process is performed to achieve the right metallurgy. The pillars in technology remain quality and efficiency with a growing emphasis on connectivity and carbon footprint visibility. The industry is benefitting from new technology that gives more input to the control process using more sensors, allowing for machine decision making. This trend is even more important today with a shrinking workforce and knowledgeable, aging employees retiring or switching jobs. With a smarter machine, there are fewer opportunities for error, shorter training periods for employees, and greater efficiencies.

There tends to be a more targeted use of software as it relates to decision-making and how to fully utilize this asset. More people are looking for quick access to information; not only on their laptop or desktop but using mobile devices as well. Many manufacturers and heat treaters are using critical notifications, pushed to them to address disruptions to the way a machine is operating. These notifications can ensure that machines have potential maintenance and safety issues addressed in a timely manner. It is well known by industry adopters of technology that there is almost too much data to sort through in a traditional way. With push notifications and user interface screens set up, users are finding the most efficient ways to sort through and take full advantage of the information presented to them.

Whether new capital equipment or technology updates to existing machines, the industry will continue to benefit from technology becoming more cost effective and easily implemented in the thermal processing industry.

Williams Industrial Service, Inc.

The Latest in Continuous Furnace Systems from Williams Industrial Service, Inc.

Over the past 50 years, Williams Industrial Service, Inc. has been designing and building high-performance industrial furnaces for the heat treating market. Some of our continuous products consist of Large Capacity Pusher Furnaces, Cast-Link Belt Furnaces, and our highly popular Mesh Belt Hardening Furnaces. They range in all sizes up to 6,000 lbs./hour and are designed for maximum performance while offering the latest features in the industry.

Below are some of the highlighted features for the Mesh Belt Hardening Furnaces by Williams:

No Part Loss or Mixing

One of the biggest challenges with a mesh belt furnace is part loss and/or part mixing. Due to the geometry of certain parts, they can roll off the side of the belt or get hung up in the quench chute area causing parts to get lost inside the furnace or mixed with other parts.

Williams has a proven design that prevents part loss or mixing. Our proprietary design allows both sides of the belt to ride on angled SIC shelves that run the entire length of the furnace continuing into the quench chute. This feature set has proven to be one of the most reliable solutions in the industry.

High Efficiency Heating Systems

Williams primarily uses single ended SIC radiant tubes in many sizes that can be electrically heated or gas fired. When properly maintained, tube life expectancy exceeds 15 years. With this configuration, if one eventually does fail the temperature uniformity is not affected. This keeps the furnace in CQI-9 compliance and maximizes uptime performance.

Mesh Belt Life

With our unique conveyance design, the life of the mesh belt in our furnaces typically lasts twice as long as the competitors. Our design includes driven return rolls and automatic clutching for precise ratio control to reduce friction on the belt for improved life.

SCADA Control System

Williams offers a fully automated, state of the art control system. This provides our customers with complete traceability of the parts including enhanced data collection and reporting capabilities.

C3 Data

website: C3data.com

CEO

C3 Data

C3 Data’s furnace compliance software continues its expansion, providing more capability and choices to help our customers meet the challenging/everchanging compliance needs of the heat treat world (Nadcap, CQI-9, etc.).

We begin 2022 by announcing that C3 Data now integrates with the heat treat industry’s leading MES/QMS software: Bluestreak. Now the furnace compliance status of any given furnace can directly inform Bluestreak and optionally prevent furnace operators from loading parts into non-compliant furnaces. Contact your C3 and/or Bluestreak representative for more information.

At C3, we understand that every heat treat job has its own unique requirements and preferred list of vendors. That’s why we’ve not only built the software specifically for the heat treat industry, but we’ve always made it work in every possible scenario. Whether you do all your pyrometry in-house, outsource it all, or a hybrid, C3 remains the flexible and configurable software for whatever your needs may be.

This past year we’ve made concerted efforts to provide even more choices for our customers. A growing list of over a dozen of the world’s best pyrometry labs now use C3 to perform on-site pyrometry services and to provide C3-integrated Field Test Instrument calibration services. This means Field Test Instrument data provided by these accredited labs is always 100% digital and free of human-error when you’re performing pyrometry tests using C3.

We’ve also very recently expanded the list of thermocouple manufacturers that C3 can digitally integrate with through a technology just released, using a “Good, Better, Best” approach. C3 customers will soon be hearing and seeing more about this and will be able to make a more informed decision about which thermocouple suppliers might be best for their specific situation.

We have lots more in the works for 2022! Check us out at: C3data.com and give the software a test drive by filling out this form: https://www.c3data.com/get-more-info/.

Nel Hydrogen

On-site Gas Generation Is a Tool for Success

Several trends are converging to renew the interest of metal thermal processors in on-site gases generation:

- Supply interruptions of delivered gases have impacted customers across all types of gases and usage segments. Unbelievably, a NASA/U.S. Space Force satellite launch was delayed by a week in September 2021 because there were not enough liquid nitrogen trailers and drivers to deliver the product to the California launch site. Delays of this sort have also become almost routine in liquid hydrogen, affecting customers nationwide.

- Reduction in carbon footprint has become a key measurable for major corporations and their supply chains. As ESG (Environmental, Sustainability, and Governance) criteria have become widespread through major corporations, the requirements are forced down through the supplier network. Whether you are getting loads of gases delivered by diesel tractor trailer or making your own atmospheres by endo or exo, be prepared to face challenges to measure and reduce your carbon footprint.

- Increasing community awareness of hazardous materials. As the scarcity of volunteer firefighters and other emergency responders has reached crisis proportions, regulators are increasingly unhappy with storage of hazardous raw materials at sites where a release can create a community emergency. Processors storing liquid ammonia for DA or liquified cryogenic hydrogen or nitrogen can expect increased scrutiny from local authorities having jurisdiction.

- Saving money and ensuring reliable production. The math is straightforward — on-site gas generation saves money versus delivered gases. It becomes compelling when delivered gases are increasing in price and becoming less reliable.

On-site generation gas technologies are advancing, becoming less expensive to own and operate, and are clearly environmentally superior. Especially for companies who are buying a green blend of electricity, on-site hydrogen and nitrogen generation is a way to simultaneously save money, reduce your carbon footprint, and win customer, worker, and environmental safety acclaim for your efforts.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com