Given the nature of this year's Furnaces North America (FNA) show, we are bringing updates from the event to you. What happened? What did they cover in the technical sessions? Who showed up? What is it like navigating a virtual platform? Learn about how the second day of the event went in the article below.

Given the nature of this year's Furnaces North America (FNA) show, we are bringing updates from the event to you. What happened? What did they cover in the technical sessions? Who showed up? What is it like navigating a virtual platform? Learn about how the second day of the event went in the article below.

If you have any videos, images, or thoughts from this year's event, email them to editor@heattreattoday.com!

Who's Who: Live Session

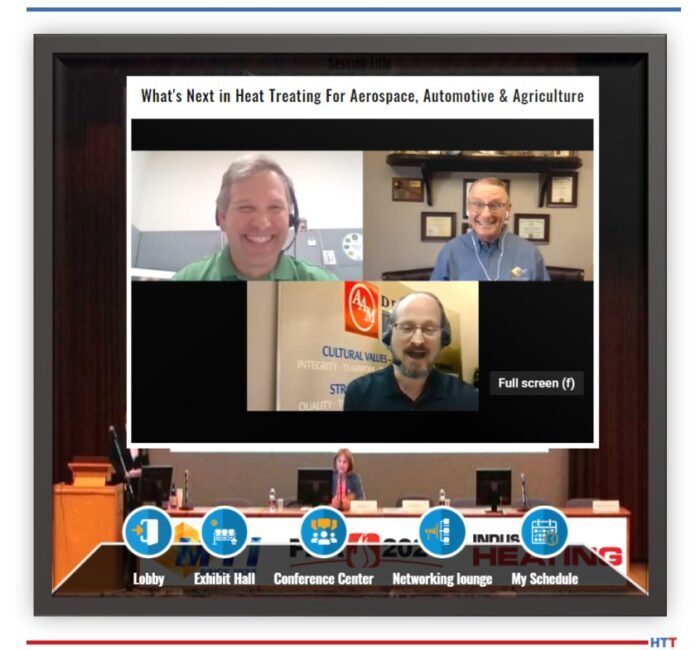

The live session on the second day was an enlightening look to the future as Tom Morrison of the Metal Treating Institute, Cory Padfield of American Axle & Manufacturing, and Chad Spore of John Deere discussed, "What's Next in Heat Treating For Aerospace, Automotive & Agriculture."

The audience heard Tom talk about how millions of dollars can be taken out of the heat treat supply chain with the advent of 3D printing, followed by Chad's assessment of current developments in the world of agriculture.

Cory shared that changes in the heat treat design within the automotive industry may look like "a shift [in the heat treat processes] from cast iron parts which have been used in automotive to steel that may need heat treatment, or heat treated cast iron, like austempered iron." He also noted that there will "definitely" be more salt quenching in the future for precision components. Furthermore, as heat treat moves away from traditional steel usage, aluminum will continue to be the material of choice. Looking to the future, Cory says to focus on part-to-part variation within the automotive industry.

Chad honed into the matured state of affairs with Industry 4.0, particularly with service components with lower volume output and needs a quicker turn around. Additionally, he talked about "measuring the green-part prior to heat treating" while using data tracking systems in order to minimize material waste to create a more specialized process. "Technology is key part...the connectivity between your equipment and the manufacturing processes is going to be a key aspect to utilize within the heat treating industry."

Check out today's schedule here.

Technical Sessions

These sessions are available 24/7 at the Furnaces North America Show. Be sure to stop by the speaker's chat room to follow-up on their talk! Note: You must register to attend Furnaces North America the Virtual Show in order to view these sessions. Click HERE.

-

Matt Clinite from Ipsen shares 5 basic principles for vacuum furnace peak performance in his session "Vacuum Furnace Best Practices for Greater Reliability and Efficiency." He recommends that we "kick the tires to make sure it is running well!" But truly, Clinite offers great advice to check the status of a seemingly perfectly fine, operational vacuum furnace. Within his 5 steps, he notes 3 signs to look for in the hot zone including checking for degrading insulation and bare steel showing through. Listen to more of his great illustrations ("furnaces are a bit like children") and follow up with him today in the FNA chat. Technical Session HERE.

-

Jenna Alder over at AFC-Holcroft. "Getting it Done Right: Manage Equipment Maintenance and Alarms with Integrated Software Solutions." Computerized Maintenance Management System alleviates the pressure of remembering and tracking every detail of maintenance processes. Alder emphasizes that should any operation go into lapse or run into error, the computerized system can track where a task was incomplete and when a task needs to be performed. More technical abilities of this type of system are elaborated in Alder's technical session. Watch it, and catch up with her today! Technical Session HERE.

-

"How Predictive Maintenance will Increase Your Profit Margins": Dan Herring -- you were waiting for us to mention him! -- talks about predictive (or preventative) maintenance that come in all shapes in sizes. Two distinct styles of maintenance practices? "Planned Preventative Maintenance Programs" (plan-execute-evaluate-revise) or "Repair As Needed Strategies" A key take-away: "Neither [maintenance style] has been proven to show a distinct cost advantage over the other," but the style of planned programs optimizes production demands of manufacturing. Technical Session HERE.

Check out today's schedule here.

Navigating the Virtual

Take advantage of...

- AFC-Holcroft’s exhibit features a brief “How Heat Treat Are You” quiz. Those who answer all the questions correctly are eligible for some really nice prizes! (Yes, another prize option!) Go to their booth HERE.

Screen capture from the FNA 2020 Virtual booth highlighting the bio section - (Again, stealth mode...) Check out the company bios to get the most out of your visit. These are great ways to learn if this is a company that you can do business with after the event.

Videos etc.

- Personal booth videos featuring drone footage (AFC-Holcroft) and golfing (Super Systems)

- Live Sessions can be accessed in the FNA after the are broadcasted, but attend live so that you can chat with other viewers and speakers.

- Technical walk-through of personal product are frequently shared on the front of an FNA booth. (Azbil North America, Inc.)

Looking for live updates of the event? Check out our social media pages @HeatTreatToday on Twitter ![]() and LinkedIn

and LinkedIn![]() to see the current happenings. Search #HeatTreatToday and #FNA2020 to watch our content!

to see the current happenings. Search #HeatTreatToday and #FNA2020 to watch our content!

original content