Source: Light Metal Age

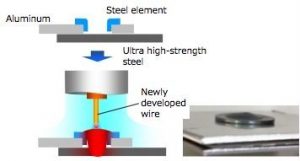

A steel manufacturer and a corporation that provides automation and robotics technologies, both from Japan, recently announced that automakers are the target users for a jointly developed experimental robotic welding system that will join dissimilar metals — such as aluminum and high strength steel — with the goal of bypassing traditional methods of assembly, including rivets, fasteners, and adhesive bonding.

Kobe Steel developed the EASW process (element arc spot welding) and FANUC Corporation adapted it to high-speed application in assembly-based manufacturing.

“Specifically, the system performs a series of actions at high speeds, including position detection, smooth and accurate movement of the robot, pressurization, feed and engagement of the rivets, and arc welding.” — Light Metal Age

Read more: “Kobe Steel and FANUC Jointly Develop Robot to Join Dissimilar Metals”