![]() Source: Manufacturing Engineering

Source: Manufacturing Engineering

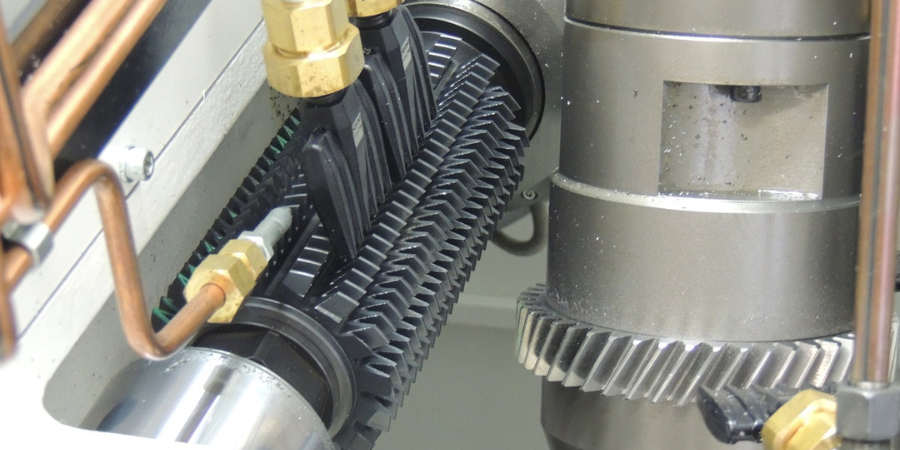

“Another dramatic change in the process itself is the move away from first hobbing a gear, then shaving it and then heat treating it. Hobbing is a multipoint cutting process that rotates both tool and workpiece in precise relations to each other. It is used to rough cut multiple gear teeth at once. “Today, automakers are hobbing gears, heat treating them and then grinding them post-heat treat. This provides a harder, more robust gear. Post-heat treat finishing of these gears eliminates distortion or changes of geometry in that gear set. The tolerance requirement after grinding is pretty critical,” he said.”

Read More: Automotive Gears and their Opportunities and Challenges