In this Technical Tuesday installment, Jim Roberts, president of U.S. Ignition, examines various flame profiles in heat treat operations. Today’s Combustion Corner compares gravitational lift, premix burners, fuel nozzle fixed air mixing burners, and nozzle mixing burners, while exploring design improvements to keep you well informed.

This informative piece was first released in Heat Treat Today’s August 2025 Automotive Heat Treating print edition.

A furnace guy walks into a bar and shouts, “Straighten UP!” The other furnace guys respond, “It won’t work!”

Thus begins another wander down combustion lane where we try to figure out what I’m talking about. We have discussed in other articles how various fuels and sources of air (and everything else) can affect the heating rates produced by our combustion equipment. We have talked about fire. We haven’t talked about what fire looks like.

So, in the following column and subsequent releases we are going to talk about flames and fire, and why there are a fairly substantial number of flame profiles available to heat treaters, steel makers, and all of you high-temp-type people. Why are there different flame shapes, and what does flame color do for you?

Burner Types

Firstly, let’s start with the various types of burners commonly used in the art of high-temp processing work.

- Gravitational lift: This type of burner is exactly what it sounds like; it works just like a candle. The fuel/air mix is naturally rising with the thermal current of the flame and combusting as the flame rises, climbing the heat column.

- Premix burners: This is where the fuel and air are mixed together and then ignited. By controlling the percentages of fuel and air in the mixture, we control the characteristics of this flame.

- Fuel nozzle fixed air mixing burners: This is where a steady stream of oxidant (air) is flowing, and the fuel is throttled up and down to affect ignition and capacity of fuel.

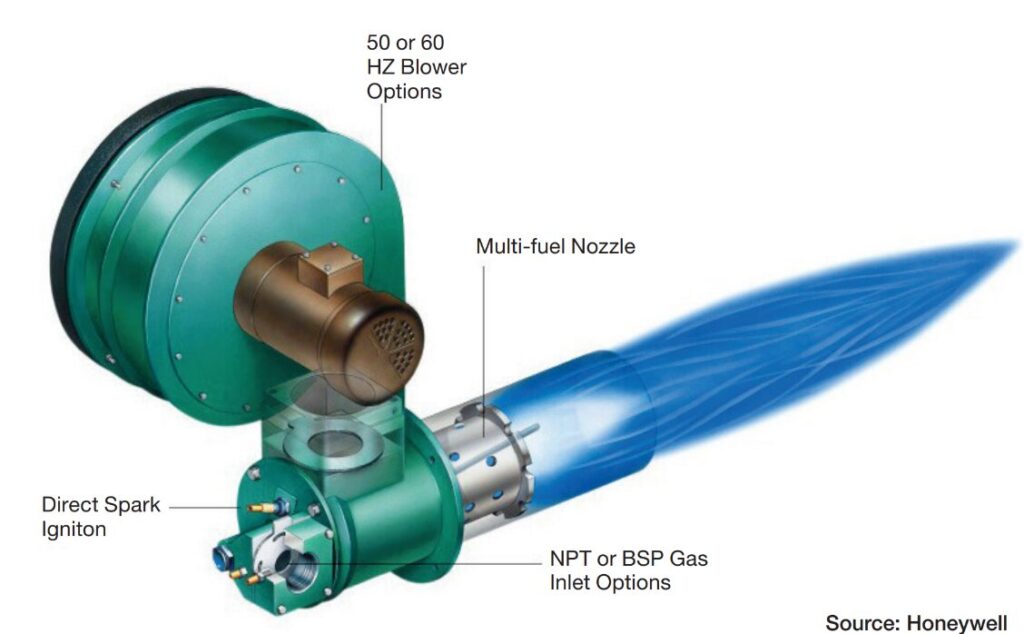

- Nozzle mixing burner: Finally, and by far the most used in our industry, this is where the fuel and oxidant mix internally in the burner, and a flame configuration is determined by the burner outlet or the mixing nozzle. (See Figures 1 and 2.) You may hear burner nozzles referred to as a cup, a spinner, flame retainer, just about any type of reference. You may also hear them referred to as a danged hot thing — an accurate description as well — so don’t touch.

Design Improvements

With development of the nozzle mixing burner 60+ years ago, design improvements began in earnest. One of the first patents for nozzle mixing industrial burners was issued to Eclipse Fuel Engineering in 1967. Pretty soon there were all sorts of designs and patents, as burner companies raced to improve reliability, performance, and heat delivery characteristics.

Some of the concepts that came along in the subsequent years were “air staged” burners. In this design feature, the fuel is delivered in the center of the flame nozzle. Progressively changing air holes in the nozzle stages the combustion of the fuel as it makes contact with the air. As the gas burns and the exhaust gas expands, it will often increase volumetrically by up to seven to eight times its cold state condition. That’s a lot of expansion, and it forces the pressure in the burner body to increase at an amazing rate. As the flame progresses through the burner and seeks the exit point (the part we see, you know, the fire), it can be moving along at — get this — flame speeds up to 400 feet per second!

That’s enough for today. We’ll pick this conversation back up next month.

President

US Ignition

For more information:

Contact Jim Roberts at jim@usignition.com