For this release from our September print edition, specifically concerned with the different “People of Heat Treat,” Heat Treat Today was curious what a group of distinguished women taking the lead in North America’s heat treat industry had to say about their experiences in a space where women are the minority. Hear a bit of their personal stories of challenge and success in the roundtable below.

This article originally appears in Heat Treat Today's September 2023 The People of Heat Treat print edition.

1. What is your “origin story” of entering the

heat treat industry?

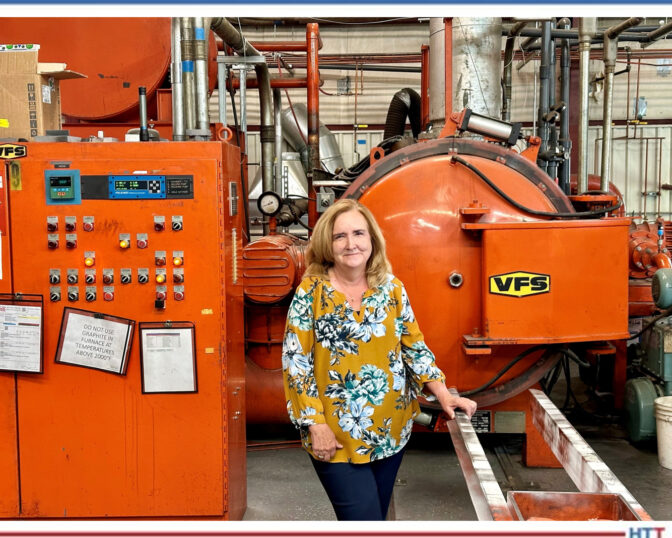

Deidra Minerd, Operations Manager & Metallurgical/Process Engineer, The Euclid Heat Treating Company: I entered the heat treating industry because it was a family business. That wasn’t my original plan, though, as I started my college career in pharmacy. Summer jobs were at the family heat treating business that my grandfather started, and one summer I decided to change schools and study metallurgical engineering, with the intent to join the business after college.

Debra James, President/CEO at METALEX THERMAL SPECIALTIES: I began working for a company that did ion nitriding in 2012. I was hired as the office administrator, but it was a small company, so we wore many hats that included helping the guys in the shop loading and unloading parts when they needed a hand. From there, it was a learning process of understanding the heat treating industry, working with customers to meet their expectations, and developing business relationships.

The gentleman that owned the company was a great mentor who encouraged growth and development. He wanted me to purchase the company, and we had started down that path when he passed away. In 2019, his successors took over the company, but they did not focus on customer service, growing the company, or making improvements.

That is when we began looking for an outside company to purchase. We were able to purchase a small heat treating company in Berthoud, Colorado. Immediately, we took steps to focus on customer service and offering updated processes to our customers. We have received very good feedback from our customers, and we have been able to grow our sales by 20% each year. We also took steps to get our Women’s Business Enterprise National Council (WBENC) certification, as well as our AS9100 certification. In addition, we were able to relocate the business to a much larger facility that will enable us to continue to grow and expand.

Mary Springer, Executive Vice President at ThermTech Of Waukesha, Inc: In 1968, my dad started his own heat treating company called Midland Metal Treating in Franklin, WI. I was 10 years old. He had worked as a tool and die heat treater at Simmons Company, and other places. He was very proud of his heat treat journeymen’s card.

Midland was very much a family endeavor. There were four of us and we all went to work with dad, mostly to spend time with him. I became an expert at running the induction hardening department. I was a tomboy, so I loved the shop environment. I worked as much as I could, in the beginning for root beer and Cheetos! However, spending hours and hours pushing a button and watching a part heat up became pretty monotonous.

My dad never dissuaded me from working with him, but I got the sense that he wanted me to go to college, yet the subject of engineering never really came up. I wanted to be an oceanographer and follow Jaques Cousteau around the globe, but found that I really did not want to leave my family. So, I ended up with several of my friends in nursing school, working for dad in the summer.

After obtaining a master’s degree in Nursing and a minor in Business Management, I worked as a nurse educator for a large hospital system and taught at the local university. In the late 1970s, the recession took its toll on Midland, and my dad had sold the company under duress.

A year later, at the age of 54, he decided to roll the dice again and started ThermTech. My brother was studying metallurgy at UW-Madison, and my older sister was working in the office. I felt a longing to be a part of it again. In 1987, I left my job at the hospital and joined my dad and siblings. Everyone did everything they could to make a go of it and little by little, we grew ThermTech. I kept a job working weekends as a home IV oncology nurse until 2004, as I did miss my old job!

As ThermTech grew, my older sister left, and my brother and I learned to work together sharing the duties of running a business. My dad retired when he was 70, and my brother and I became equal stock owners.

2. Have there been any challenges that you’ve

encountered in heat treat?

Deidra Minerd: One challenge I faced when I started was translating what I learned in college to what was happening on the shop floor. I had a lot of book knowledge, but I didn’t know how to run a heat treating furnace. I had to make the effort to learn from people on the shop floor, ask questions (even if they sounded like stupid questions), and get my hands dirty so I could learn and earn their respect.

Debra James: Occasionally I encounter people who do not think women really belong in the heat treating industry and assume that I am just an employee rather than an owner of the business. The other major hurdle that we have encountered is getting financing for equipment. Our equipment purchases are usually used equipment due to the prohibitive costs of new equipment and being able to access financing for used equipment can be difficult.

Mary Springer: Heat treating is VERY challenging. Different problems every day. That is what I love about it. I work hard to develop relationships with employees. Currently, we employ 155 people, we run 3 shifts 24 hours/6 days a week. I love planning expansion, figuring out financing on large projects, and solving problems.

3. What solidified your leadership in this industry?

Deidra Minerd: While I certainly don’t feel like an expert, I’m reminded every now and then that I have certainly collected quite a bit of expertise over the years. An important lesson I learned, however, is that having the most technical knowledge does not necessarily make you the best leader. There is an additional set of skills necessary to successfully lead a group of people and/or a business, and that set includes humility, patience, integrity, good communication skills, and the ability to see the big picture and be open to change. Years ago, my mentor, Roger Fabian, suggested that I would be a good leader in my company, and that was an important moment for me. He had been a leader in the heat treating industry, and I valued his opinion and appreciated that he noticed that in me.

Debra James: The key factor that solidified my desire to own our heat treating business was first the support and encouragement that I had received from the gentleman that originally owned the ion nitriding company I worked for. He was a very knowledgeable person and knowing that he thought I could run my own heat treating business made me see that possibility. In addition, knowing that I could do a better job of owning, managing, and operating a company than the successors that took over his business was also a motivating factor.

Mary Springer: As a company, the realization that my brother and I have built a “brand” in the industry, watching our sales/profit grow, and knowing how proud our mom and dad would be of what we did with the great opportunity they afforded us . . . feels very nice. Also, we each have a son in the business, and they are coming into their own, hearing their ideas for the future . . . exciting! I guess I do not consider myself an expert in the industry, only someone who is hardworking and always curious!

4. Any advice you’d give to women in heat treat to enjoy and “own” their position?

Deidra Minerd: My advice to women would be to “own” their knowledge and be confident in it, but also be willing to ask questions. I think young people may be hesitant to say they don’t know something, for fear of not being perceived as “smart.” However, a lot of knowledge is gained from peers instead of from books, so the ability to constantly learn is important.

Debra James: First of all, embrace this industry and realize all that there is to learn. Always be looking at ways to improve what you do and how you can best meet your customer’s needs. Establish yourself as the person the customer/contact needs to talk to.

Mary Springer: For me this has never been about being a “woman in a man’s world.” I have never experienced anything but acceptance in this industry. Working hard is working hard. If you put your best effort forward, you will enjoy the fruits of that effort. Dedication earns respect, there’s no other way around it. Never stop learning, and remember, no one can “have it all.” Choices have consequences, good and not so good. But never complain about the consequences of your choices, you have to own it. Don’t do it if you don’t love it!

5. What is the best part of the heat treat industry?

Deidra Minerd: What I love about heat treating is the history and consistency of metallurgy. You can have a very fancy furnace that follows a program minute-by-minute with thermocouples to monitor the temperature of the part, or you could heat it up in an open-fire furnace and quench it with tongs in a 5 gallon bucket of oil, and it will respond the same way. New technology doesn’t change the basics of metallurgy.

Debra James: The best part of the industry is that there is always something to learn and new avenues to explore for growth and development of yourself personally and professionally. I truly enjoy our customers and the relationships that we have built with them. It is so rewarding when they tell us how much they appreciate what we do for them.

Mary Springer: In commercial heat treating, I find it very challenging to anticipate the needs of our regional market, to be able to reinvent ourselves technically to serve new demands. It is exciting to bring new equipment in and see the growth. I love to see our people grow and learn, prosper from their careers here. We have many people with over 15 years’ experience. Figuring out how to connect with the younger generation has been a journey . . . . Also, it is always interesting, but difficult to learn from mistakes. Surviving whatever! I remember in late 2019, my sales manager came in one day and said, “Do we have a plan for a pandemic? There is this COVID thing going on in China . . .” I kind of chuckled and said, “It’s just the flu!!!!” HA! You just never know where the next challenge will come from. Try always to keep a light heart.

About the Industry Leaders

Deidra Minerd is the Operations Manager & Metallurgical/Process Engineer at The Euclid Heat Treating Company.

Debra James is the president/CEO at METALEX THERMAL SPECIALTIES.

Mary Springer is the Executive Vice President at ThermTech of Waukesha, Inc.