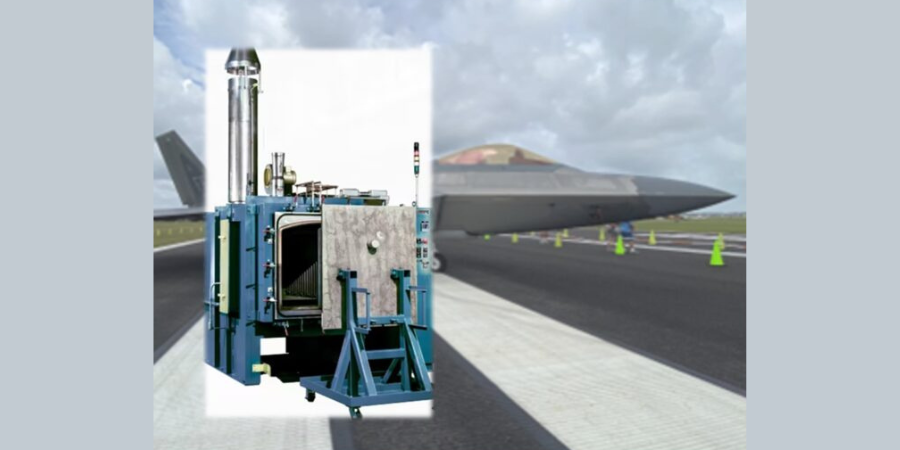

A heat treat furnace has been delivered to a Midwest manufacturer of ceramic matrix parts. This system will be used for aerospace and military purposes.

A heat treat furnace has been delivered to a Midwest manufacturer of ceramic matrix parts. This system will be used for aerospace and military purposes.

Source: L&L Special Furnace Company, Inc.

Ceramic matrix parts materialize when nanofibers of silicon carbide or other ceramic nano threads are wound together, forming various sheets and 3D-printed shapes. The nano threads in the process are coated with proprietary resins that must be completely removed from the substructure using heat. The resulting finished product is lighter and stronger than titanium.

L&L Special Furnace Company, Inc.'s Model XLC3672 has a work zone of 32” wide by 32” high by 66” deep. It has a single zone of control with a temperature gradient of ±20°F at 1,100°F using four zones of temperature control with biasing to balance any temperature gradients. The Model XLC3672 is controlled by a Eurotherm Nanodac Mini 8 program mechanism with overtemperature protection.